Bamboo charcoal slurry for viscose collagen solution spinning and preparation method thereof

A technology for viscose collagen liquid and bamboo charcoal pulp is applied in the fields of bamboo charcoal pulp and its preparation, bamboo charcoal pulp for viscose collagen liquid spinning and its preparation, which can solve problems such as poor dispersion performance, and achieve good stability, mild irritation and the like. Small, well-sourced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

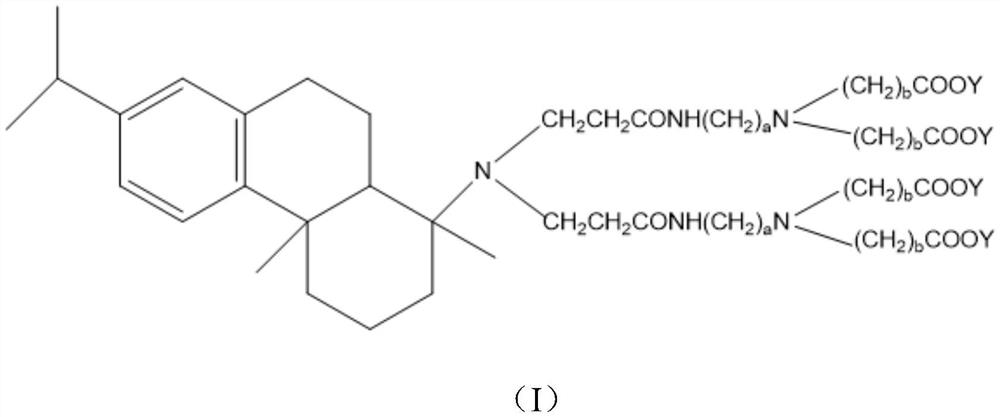

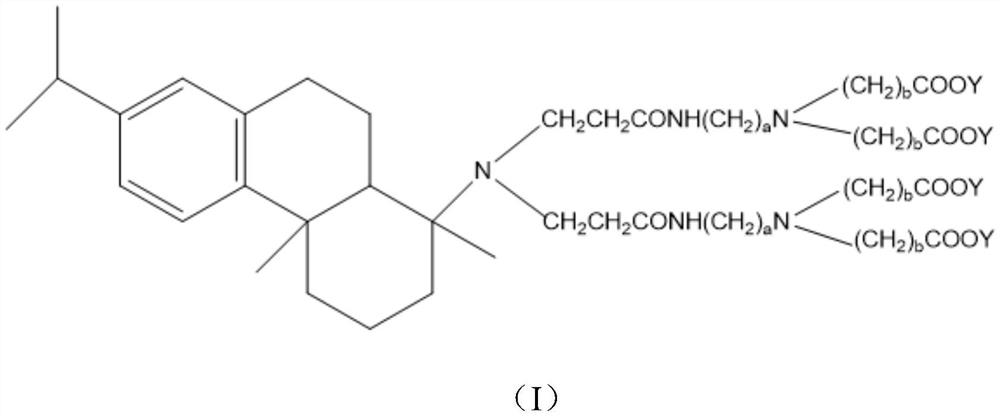

Method used

Image

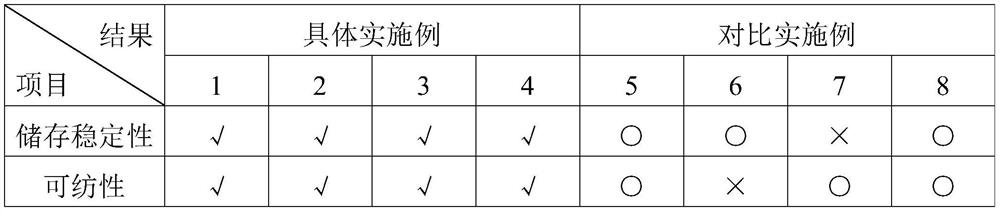

Examples

specific Embodiment 1

[0037]After dissolving 0.1 mass parts of protein-type surfactant, 0.6 mass parts of rosin-based hyperbranched surfactant B1, 3 mass parts of hydroxymethyl cellulose, and 0.5 mass parts of imidazole antifungal and fungicide into 74.3 mass parts of water, use hydrogen Sodium oxide is used as a pH value regulator to adjust the pH value of the solution to 8.0, and mix evenly; 21 parts by mass of bamboo charcoal powder are added to the mixed solution, and the bamboo charcoal slurry is obtained through dispersion, grinding, and filtration, wherein 0.5 parts by mass of polyether compound are added during the grinding process defoamer.

specific Embodiment 2

[0039] 0.2 parts by mass of protein surfactant, 0.05 part by mass of rosin-based hyperbranched surfactant B2, 1 part by mass of hydroxyethyl cellulose and 1 part by mass of hydroxypropyl methylcellulose, 0.05 part by mass of thiazoles for mildew and sterilization After the agent is dissolved in 87.5 parts by mass of water, potassium hydroxide is used as a pH regulator to adjust the pH value of the solution to 9.0, and mixed uniformly; 10 parts by mass of bamboo charcoal powder are added in the mixed solution, and the bamboo charcoal slurry is obtained through dispersion, grinding and filtration. In the grinding process, 0.05 parts by mass of polysiloxane ether copolymer and 0.15 parts by mass of polyether compound defoamer are added.

specific Embodiment 3

[0041] 0.9 parts by mass of protein surfactant, 0.6 parts by mass of rosin-based hyperbranched surfactant B3, 1 part by mass of methyl hydroxyethyl cellulose, and 0.3 parts by mass of isothiazolone derivative antifungal and fungicide are dissolved to 66.9 parts by mass After being in water, use ammonia water as a pH value regulator to adjust the pH value of the solution to 10.0, and mix evenly; 30 parts by mass of bamboo charcoal powder are added to the mixed solution, and the bamboo charcoal slurry is obtained through dispersion, grinding, and filtration, wherein 0.3 parts by mass of polycarbonate are added during the grinding process. Silicone ether copolymer defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com