Wax remover used for metal polishing part and preparation process thereof

A technology for removing wax water and metal, applied in the field of wax removing water and its preparation process, can solve the problems of poor wax cleaning effect, difficulty in achieving clean and bright, eutrophication of water body, etc. Water-based and dirt-repellent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A kind of dewaxing water for metal polishing parts, each component and its corresponding parts by weight are shown in Table 1. Among them, the surfactant is compounded by polyether-modified polysiloxane and isomeric alcohol oleic acid soap, and its mass ratio is 1:5; the organic base is diethanolamine and diethylenetriamine, and its mass ratio 1:1, were purchased from diethanolamine D112359 of Shanghai Aladdin Technology Co., Ltd. and diethylenetriamine 111-40-0 of Nanjing Mangyuan Asahi Chemical Co., Ltd.; isomeric alcohol oleic acid soap was purchased from Shenzhen Canon Isomerized alcohol oleic acid soap JN-108 from Detergent Co., Ltd.; phosphorus-free chelating agent was purchased from Hebei Synergy Environmental Technology Co., Ltd. iminodisuccinic acid sodium salt IDS; organic solvent was purchased from Shanghai Yuanyi Chemical Co., Ltd. Glycerol 56-81-5.

[0029] The preparation technology of polyether modified polysilane comprises the following st...

Embodiment 2-5

[0038] Example 2-5: a wax removal water for metal polishing parts. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

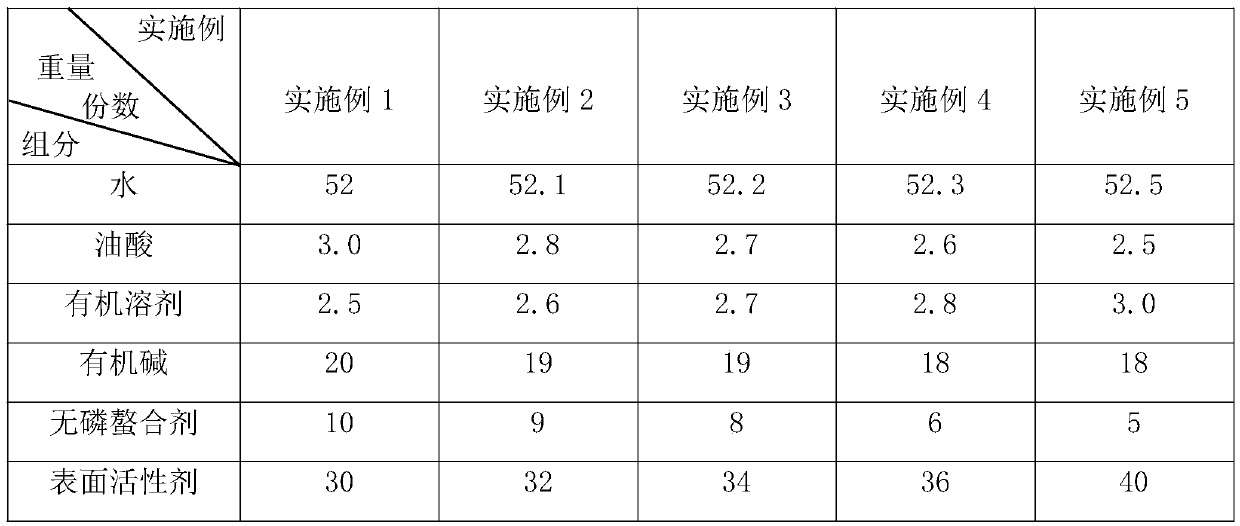

[0039] Each component and parts by weight thereof in table 1 embodiment 1-5

[0040]

Embodiment 6

[0041] Embodiment 6: A kind of wax removal water for metal polishing parts, the difference from Example 1 is that in the preparation process of wax removal water, polyether modified polysiloxane and polyether modified polysiloxane in the surfactant of step 1 The mass ratio of isomeric alcohol oleic acid soap is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com