Anti-overflow rice cooker

A rice cooker and anti-overflow technology, which is applied in the direction of anti-overflow, cooking utensils, household utensils, etc., can solve problems such as the unsatisfactory bubble breaking effect of convex ribs, the inability to effectively solve the overflow problem, and easy to hinder the normal rotation of fan blades, etc., so as to prevent The effects of bubble overflow, safe use and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

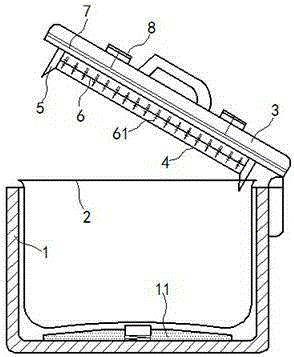

[0012] exist figure 1 In the shown embodiment, the anti-overflow electric rice cooker includes a pot body 1, an inner container 2 and a cover body 3; a heating plate 11 is installed on the inner bottom surface of the pot body 1; A hard orifice 4 is installed, and an annular guide groove 5 is also installed on the outer edge of the hard orifice 4. On the side wall where the guide groove 5 is connected with the hard orifice 4, there are Guide holes; a defoaming plate 6 is installed between the hard orifice plate 4 and the cover 3, and defoaming needles 61 are equidistantly arrayed on the defoaming plate 6, and the defoaming needles 61 Made of ferromagnetic material, the defoaming needle 61 can vibrate up and down in the vertical direction; the defoaming needle 61 is a hollow structure, and the aperture of the defoaming needle 61 is 0.5-1.5mm; the defoaming needle 61 The aperture at the upper end is large and the aperture at the lower end is small; a drive screen 7 is also insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com