High-conductivity polymer-carbon-based composite aerogel and production method thereof

A composite airgel, high conductivity technology, applied in the field of nanometer and material chemistry, can solve the problems of production cost and commercial application, and achieve the effect of good structural integrity, high surface area-volume ratio, and enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The preparation of the polymer precursor adopts a polymer with at least one carboxyl functional group and a polymer with at least one alcohol group, and the ratio of water and ethanol (or other organic solvents) is 0:1~99.9:1v / v (volume ratio ), the temperature range is 40 ℃ ~ 95 ℃ solution, with hydroiodic acid as a catalyst to form under stirring. The former uses, for example (but not limited to), 4-carboxybenzaldehyde (CAS: 619-66-9), and the latter uses, for example (but not limited to), polyvinyl alcohol (CAS: 9002-89-5). Firstly, 4-carboxybenzaldehyde (selected according to the ratio) was dissolved in ethanol and vigorously stirred at 55°C for at least 30 minutes. When completely dissolved, the corresponding polyvinyl alcohol was added to the solution and stirred at 80 °C for at least 4 hours. The use of hydriodic acid dehydrogenates two precursor polymer molecules while forming a conjugated bond in the main polymer chain. In the examples presented here, polyviny...

Embodiment 1

[0038] Obtain dry graphite oxide through graphite oxide flakes by Hummers method, then add dry graphite oxide into 99.9% ethanol solution, and mildly sonicate to form a 7.5 mg / mL dispersion. The dispersion was poured into a 100 mL beaker, and combined with the prepared polymer precursor at a mass ratio of 10:1. In this step, it is very important to maintain relatively high concentrations of the two solutions in order to allow easier aggregation of graphene oxide sheets with the polymer and to avoid monolithic dispersion in the dispersion medium. Then react the obtained solution in a water bath not higher than 85° C. for about 60 minutes to obtain tough graphene oxide wet gel. The wet gel has formed a network structure inside, but all the pores are filled by the dispersion medium. Then with supercritical CO 2 Dry the wet gel to extract the dispersion medium. Put the wet gel into the extraction chamber, under the pressure of 7.5MPa and the temperature of 50℃, with liquid CO ...

Embodiment 2

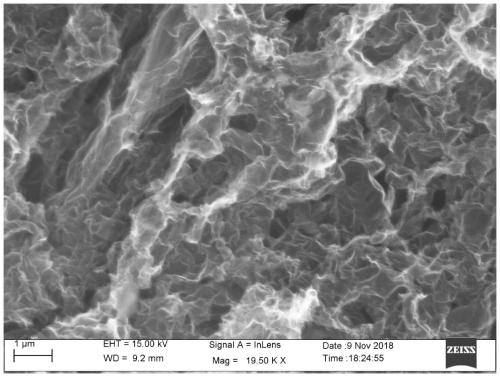

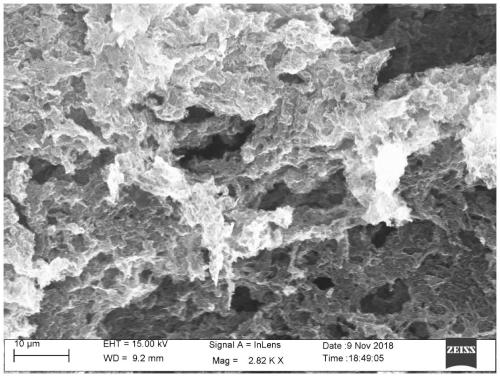

[0041] Another graphene oxide airgel was prepared in the same manner as in Example 1, except that the polymer solution was added to the dispersion at a ratio of 2.5:1. The resulting polymer-graphene oxide composite airgel is as figure 1 (middle), it has a more compact and less brittle structure than other aerogels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com