Terafluoroethylene-propylene rubber composition resistant to hydrogen sulfide corrosion and application thereof

A tetrapropylene fluoride rubber and hydrogen sulfide-resistant technology, which is applied in the field of polymer rubber materials, can solve the problems of low hardness, poor low temperature resistance of tetrapropylene fluorine rubber, and the inability to meet the requirements of anti-implosion and anti-extrusion deformation. The effect of excellent hydrogen sulfide corrosion, optimized vulcanization system, and excellent hydrogen sulfide corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

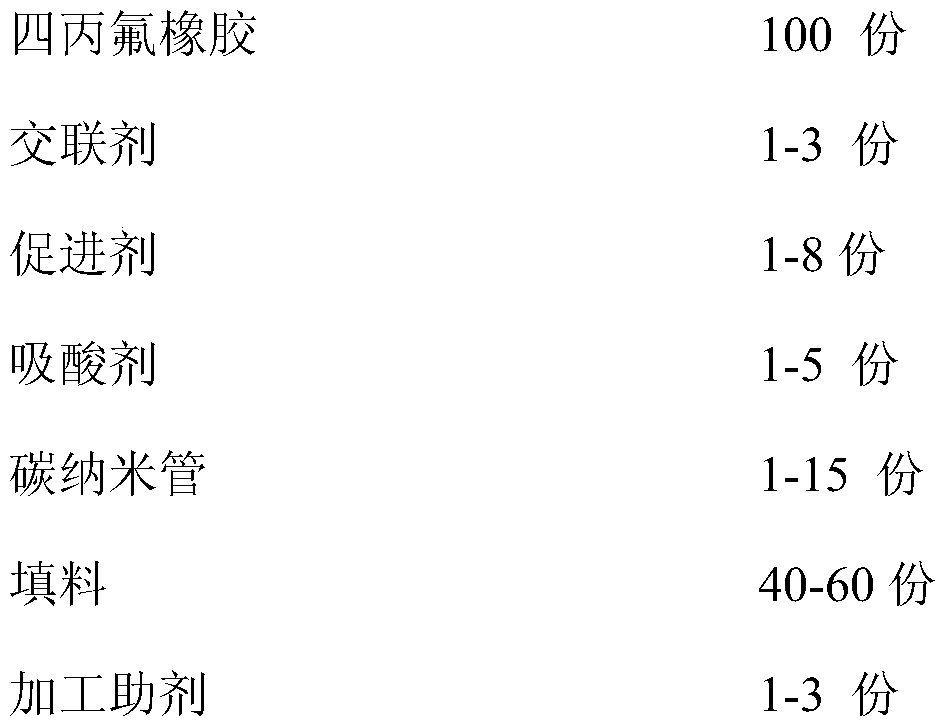

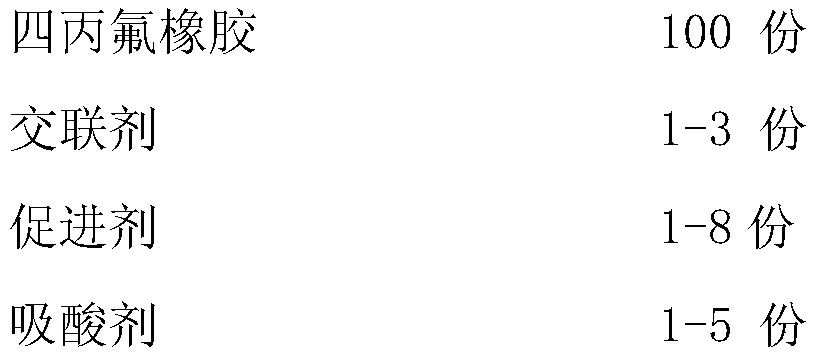

[0025] Embodiment 1: a kind of tetrapropylene fluororubber composition resistant to hydrogen sulfide corrosion

[0026] Table 1 is the formulation of No. 1 to No. 6 tetrapropylene fluororubber compositions, wherein the detailed weight ratio of each component in the raw material is shown in Table 1.

[0027] Table 1 No. 1-6 tetrapropylene fluororubber composition formula

[0028] serial number number 1 number 2 number 3 No 4 Number 5 number 6 FEPM Rubber Aflas 100S 100.00 100.00 100.00 100.00 FEPM Rubber Viton ETP600S 100.00 100.00 carbon nanotube GTR 5.00 10.00 5.00 Accelerator TAIC-S70 7.00 7.00 7.00 7.00 4.00 4.00 Crosslinker P14-40 2.50 2.50 2.50 2.50 Crosslinker 101XL-45 1.50 1.50 Zinc oxide META-Z 102 3.00 3.00 Carbon Black N990 20.00 15.00 20.00 20.00 50.00 20.00 Carbon black N774 25.00 Carbon Black N550 35.00 30.00 30.00 ...

Embodiment 2

[0030] (1) Performance test of tetrapropylene fluororubber composition

[0031] Each component was weighed according to the proportions of No. 1 to No. 6 formulations (parts by weight) in Example 1, and the tetrapropylene fluororubber was rolled on a double-bar opener, and carbon nanotubes, cross-linking agents, accelerators, suction Add the auxiliary materials such as acid agent, carbon black and processing aids into the open mill and mix with tetrapropylene fluororubber. Cut the rubber mixture on the left and right sides of the rolls 8 times each, adjust the roll distance of the mill to the smallest, roll or make triangles. The bag method is 10 times, the entire mixing time is controlled within 15 minutes, and the roll temperature of the open mill is controlled below 80 ° C, so that the rubber material is mixed evenly and then sliced to obtain a tetrapropylene fluororubber compounded rubber. After the propylene fluoride rubber compound was aged for 16 hours, it was returne...

Embodiment 3

[0048] Example 3: Preparation of tetrapropylene fluororubber composition

[0049] (1) 100 parts by weight of tetrafluoroethylene-propylene polymer Aflas 100S was uniformly masticated on a two-roll mill and rolled, and then 15 parts by weight of carbon nanotubes, 1 part by weight of 1,3-bis( tert-butylperoxy) dicumylbenzene, 1 part by weight of triallyl isocyanurate, 40 parts by weight of filler carbon black N990, 1 part by weight of sodium stearate were mixed uniformly in advance, and gradually Add it to the open mill, and mix the tetrapropylene fluororubber with the auxiliary materials;

[0050] (2) After mixing the tetrapropylene fluororubber with the auxiliary materials, cut the rubber mixture on the left and right sides of the roll wrapping knives 5 times each, adjust the roll distance of the open mill to the minimum, roll or roll the triangular wrapping method 10 times, and control the whole mixing time at Between 15 minutes, the roll temperature of the open mill is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com