Granulation processing device for compound fertilizer and granulation processing method of device

A processing device and compound fertilizer technology, applied in the field of compound fertilizer, can solve the problems of unbalanced particle size and quality, shorten the life of production equipment, and poor absorption of crops, so as to reduce drying energy consumption, increase product selling point and cost, and strengthen The effect of market competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

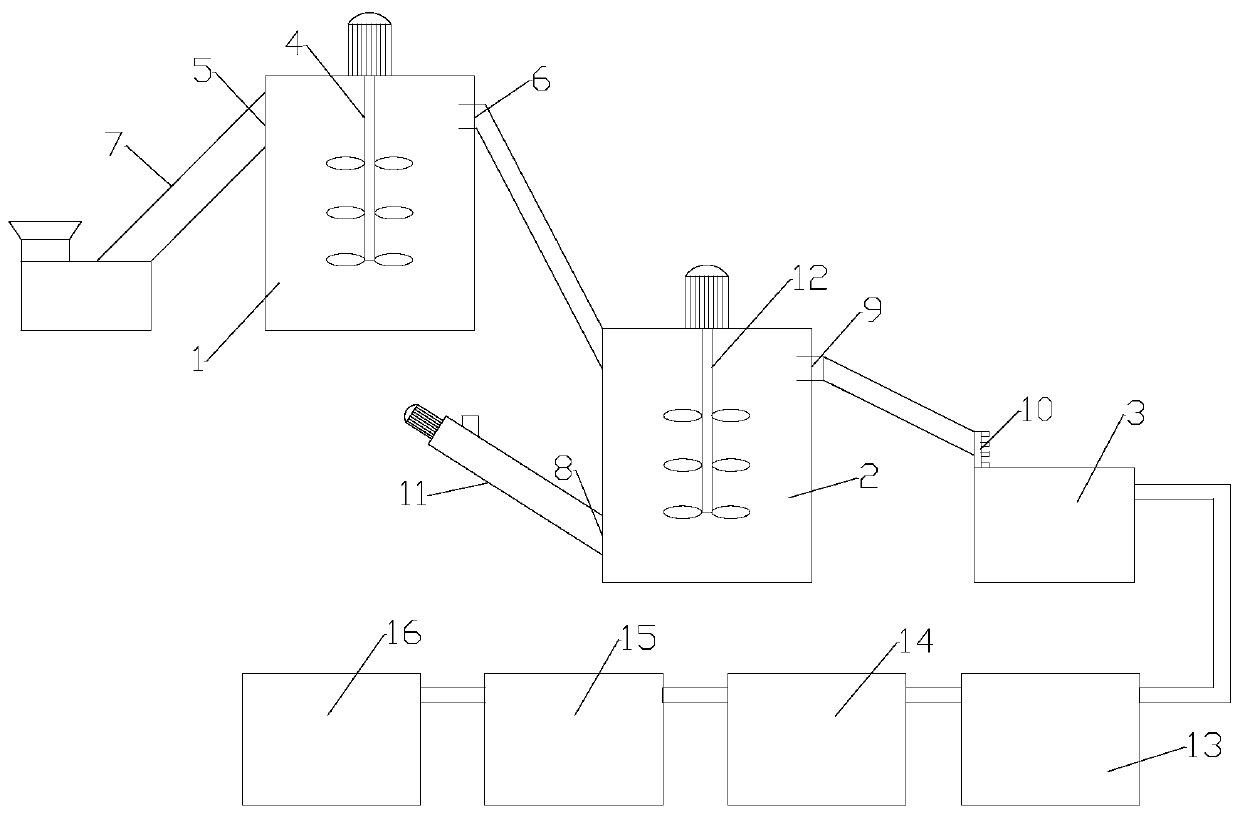

[0019] Embodiment 1: as figure 1 As shown, a compound fertilizer granulation processing device includes a urea dissolving tank 1, a mixing dissolving tank 2, a drum granulator 3, a first mixer 4 is arranged on the top of the urea dissolving tank, and a urea dissolving tank is provided on the upper side of the urea dissolving tank. Feed port 5, the other side of the urea dissolving tank is provided with a first overflow port 6, the first overflow port is connected to the mixing and dissolving tank 2 through pipelines, the top of the mixing and dissolving tank is provided with a second stirrer 12, the mixing and dissolving tank The side is provided with a powder feed port 8, the side of the mixing and dissolving tank is also provided with a second overflow port 9, and the drum granulator is provided with a spray head 10, and the second overflow port is connected to the spray head through a pipeline superior. The powder feed port is located under the side of the mixing and disso...

Embodiment 2

[0028] Embodiment 2: as figure 1 As shown, a compound fertilizer granulation processing device includes a urea dissolving tank 1, a mixing dissolving tank 2, a drum granulator 3, a first mixer 4 is arranged on the top of the urea dissolving tank, and a urea dissolving tank is provided on the upper side of the urea dissolving tank. Feed port 5, the other side of the urea dissolving tank is provided with a first overflow port 6, the first overflow port is connected to the mixing and dissolving tank 2 through pipelines, the top of the mixing and dissolving tank is provided with a second stirrer 12, the mixing and dissolving tank The side is provided with a powder feed port 8, the side of the mixing and dissolving tank is also provided with a second overflow port 9, and the drum granulator is provided with a spray nozzle 10, and the second overflow port 9 is connected to the spray nozzle through a pipeline. on the head. The powder feed port is located under the side of the mixing...

Embodiment 3

[0037] Embodiment 3: as figure 1 As shown, a compound fertilizer granulation processing device includes a urea dissolving tank 1, a mixing dissolving tank 2, a drum granulator 3, a first mixer 4 is arranged on the top of the urea dissolving tank, and a urea dissolving tank is provided on the upper side of the urea dissolving tank. Feed port 5, the other side of the urea dissolving tank is provided with a first overflow port 6, the first overflow port 6 is connected to the mixing and dissolving tank 2 through pipelines, the top of the mixing and dissolving tank is provided with a second stirrer, the mixing and dissolving tank The side is provided with a powder feed port 8, and the side of the mixing and dissolving tank is also provided with a second overflow port 9. The drum granulator 3 is provided with a spray head 10, and the second overflow port 9 is connected to the On the spray head 10. The powder feed port 8 is located at the side of the mixing and dissolving tank, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com