Carbon nitride compounded chromium sesquioxide oxygen-vacancy-containing photo-thermal catalyst as well as preparation method and application thereof

A technology of chromium trioxide and carbon nitride, which is used in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as low catalytic activity, achieve no environmental pollution, reduce costs, and inhibit current-carrying. The effect of subcompositing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Photothermal Catalysts Containing Oxygen Defects in Chromium Trioxide Composite with Carbon Nitride

[0022] (1) The preparation method is as follows

[0023] Dissolve 2.52g of melamine and 4g of chromium nitrate nonahydrate in 80ml of deionized water, stir for 1 hour, and dry at 60°C to obtain a precursor.

[0024] The precursor was ground and calcined at 500°C for 2h in the air environment with a heating rate of 5°C / min to obtain a carbon nitride composite chromium trioxide photothermal catalyst containing oxygen defects, marked as 500-CN.

[0025] (2) Detection

[0026] figure 1 500-CN prepared for Example 1 and pure Cr 2 o 3 The XRD test pattern, by figure 1 It can be seen that the sample 500-CN has diffraction peaks at 24.6°C, 33.7°C, 36.3°C, 40.0°C and 41.5°C, which are different from pure Cr 2 o 3 The characteristic peaks are similar, which proves that 500-CN has been successfully synthesized, and the sample 500-CN does not have two diffraction peaks at 13...

Embodiment 2

[0028] Photothermal Catalysts Containing Oxygen Defects in Chromium Trioxide Composite with Carbon Nitride

[0029] (1) The preparation method is as follows

[0030] Dissolve 2.52g of melamine and 4g of chromium nitrate nonahydrate in 80ml of deionized water, stir for 1 hour, and dry at 60°C to obtain a precursor.

[0031] The precursor was ground and calcined at 600°C for 2 hours in an air environment with a heating rate of 5°C / min to obtain a carbon nitride composite chromium trioxide photothermal catalyst containing oxygen defects, marked as 600-CN.

[0032] (2) Detection

[0033] figure 2 600-CN prepared for Example 2 and pure Cr 2 o 3 The XRD test pattern, by figure 2 It can be seen that the sample 600-CN has diffraction peaks at 24.6°C, 33.7°C, 36.3°C, 40.0°C and 41.5°C, which is similar to that of pure Cr 2 o 3 The characteristic peaks are similar, which proves that 600-CN has been successfully synthesized, and the sample 600-CN does not have two diffraction pe...

Embodiment 3

[0035] Photothermal Catalysts Containing Oxygen Defects in Chromium Trioxide Composite with Carbon Nitride

[0036] (1) The preparation method is as follows

[0037] Dissolve 2.52g of melamine and 4g of chromium nitrate nonahydrate in 80ml of deionized water, stir for 1 hour, and dry at 60°C to obtain a precursor.

[0038] The precursor was ground and calcined at 800°C for 2h in the air environment with a heating rate of 5°C / min to obtain a carbon nitride composite chromium trioxide photothermal catalyst containing oxygen defects, marked as 800-CN.

[0039] (2) Detection

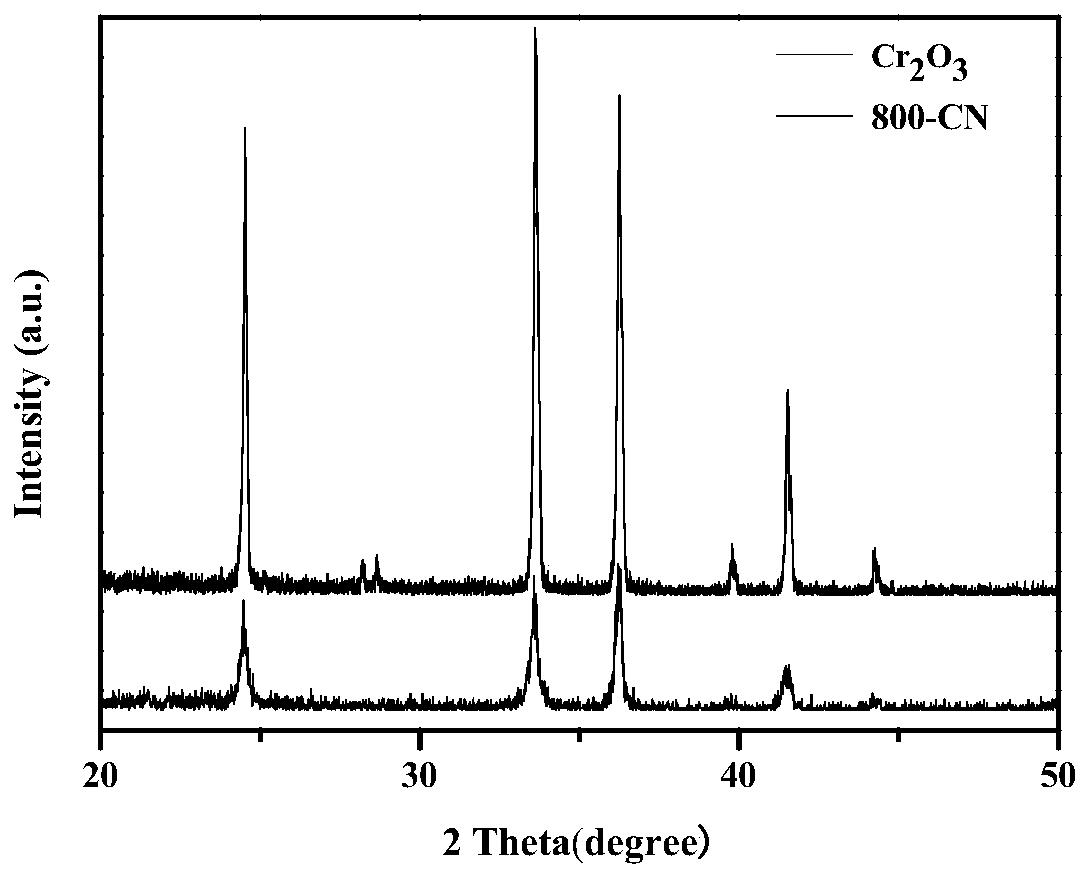

[0040] image 3 500-CN prepared for Example 3 and pure Cr 2 o 3 The XRD test pattern, by image 3 It can be seen that the sample 800-CN has diffraction peaks at 24.6°C, 33.7°C, 36.3°C, 40.0°C and 41.5°C, which are different from pure Cr 2 o 3 The characteristic peaks are similar, which proves that 800-CN has been successfully synthesized, and the sample 800-CN does not have two diffraction peaks at 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com