Pretreatment method of high-pressure liquid component

A high-pressure liquid and pretreatment technology, which is applied in the direction of material separation, material analysis, measuring devices, etc., can solve the problems that it is difficult to control the pressure of the sample to be tested, the heat capacity is large, and the quantitative analysis of liquid components cannot be reacted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0051] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

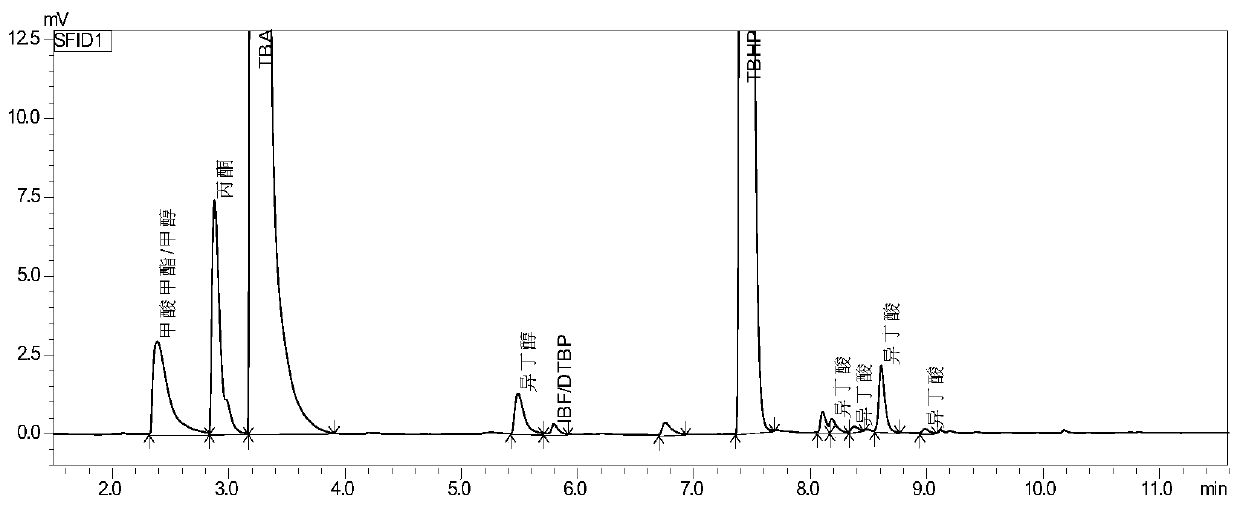

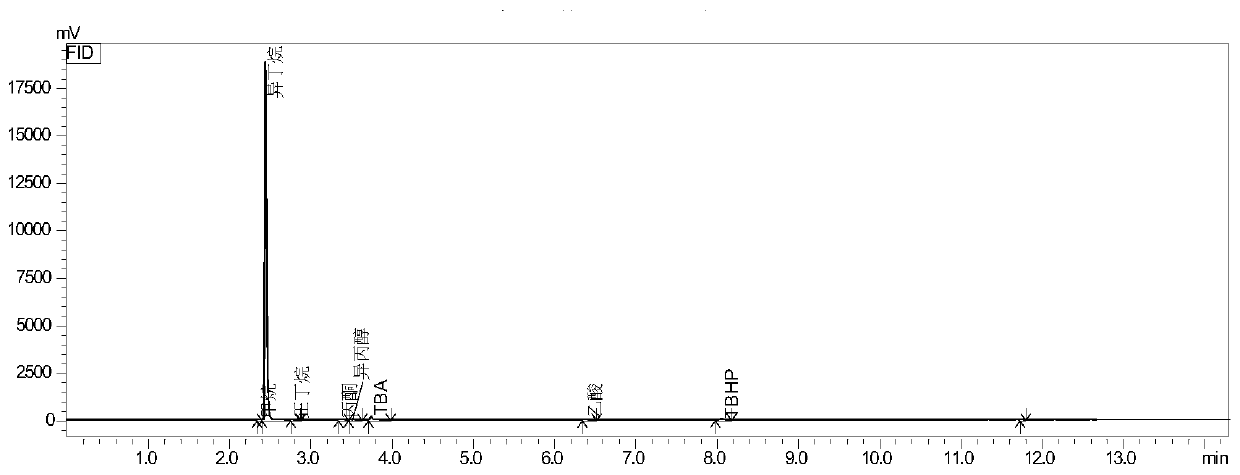

[0053] 1 The sample is the high-pressure liquid component obtained after the pilot test of isobutane oxidation

[0054] 2 Pretreatment of samples

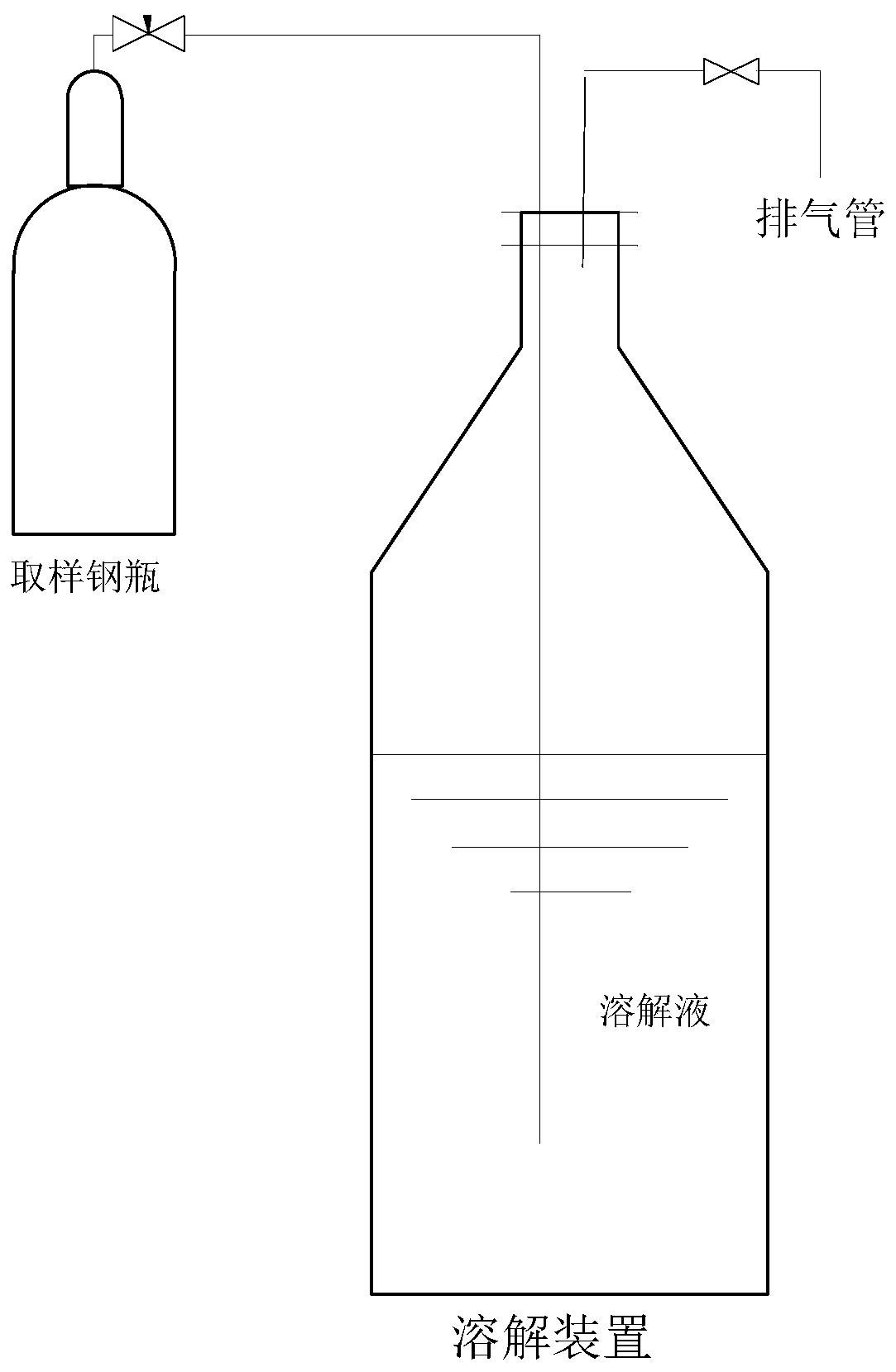

[0055] Weigh the sampling cylinder, accurate to 0.01g, recorded as m 0 . Add about 150g of water to a three-necked flask with a shut-off valve, accurate to 0.01g, and record the weight as M 1 ; Weigh the total mass of the cylinders that have been sampled m 1 , accurate to 0.01g. Connect the three-necked flask to the sampling small steel cylinder, and connect the sampling bag to the other port of the three-necked flask. After the connection is completed, the whole system is evacuated. Then fill the whole system with high-purity nitrogen to replace the air in the system. After the replacement is completed, close the nitrogen filling valve. Slowly open the outlet valve of the steel cylinder to avoid splashing of bubbles emerging from the liquid surface, and release the liquid within 8-10 minutes. Replace the nitrogen in the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com