Fluorescence intensity ratio temperature measurement method based on mixed temperature sensing material

A fluorescence intensity ratio and fluorescence band technology, applied in the field of fluorescence intensity ratio temperature measurement, can solve the problems of high sensitivity and low uncertainty, and achieve the effect of short response time, good repeatability, and changing temperature measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

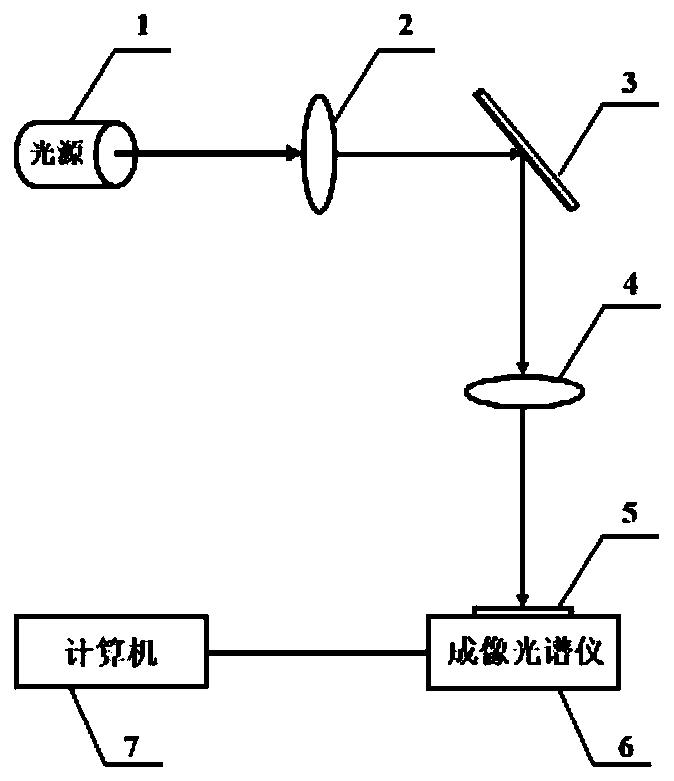

[0027] Specific embodiment one: In this embodiment, a method for measuring temperature based on the fluorescence intensity ratio of a mixed temperature-sensitive material is carried out according to the following steps:

[0028] One, the Eu 3+ : AVO 4 with Cr 3+ :Al 2 o 3 Mix to obtain a temperature-sensitive material;

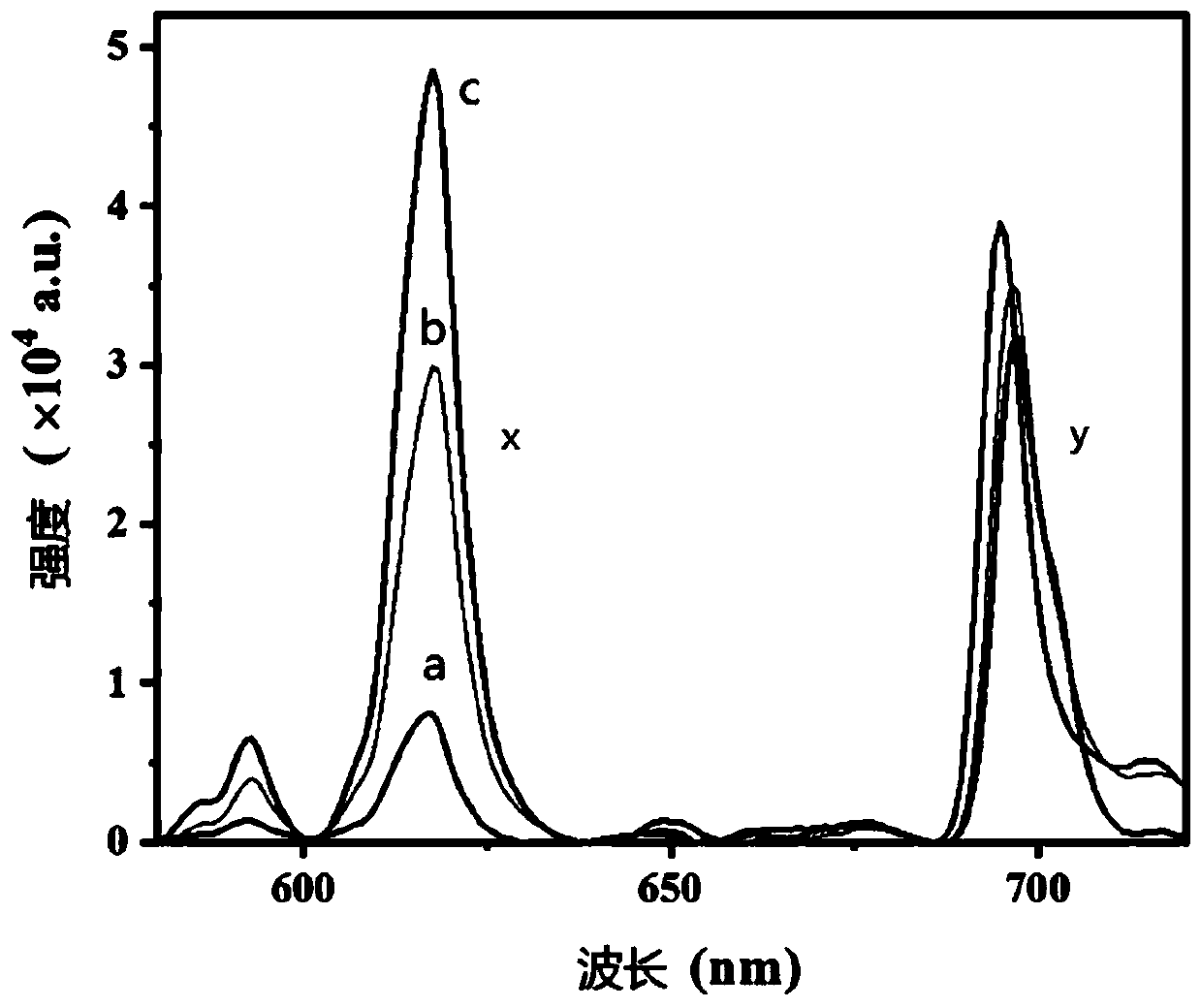

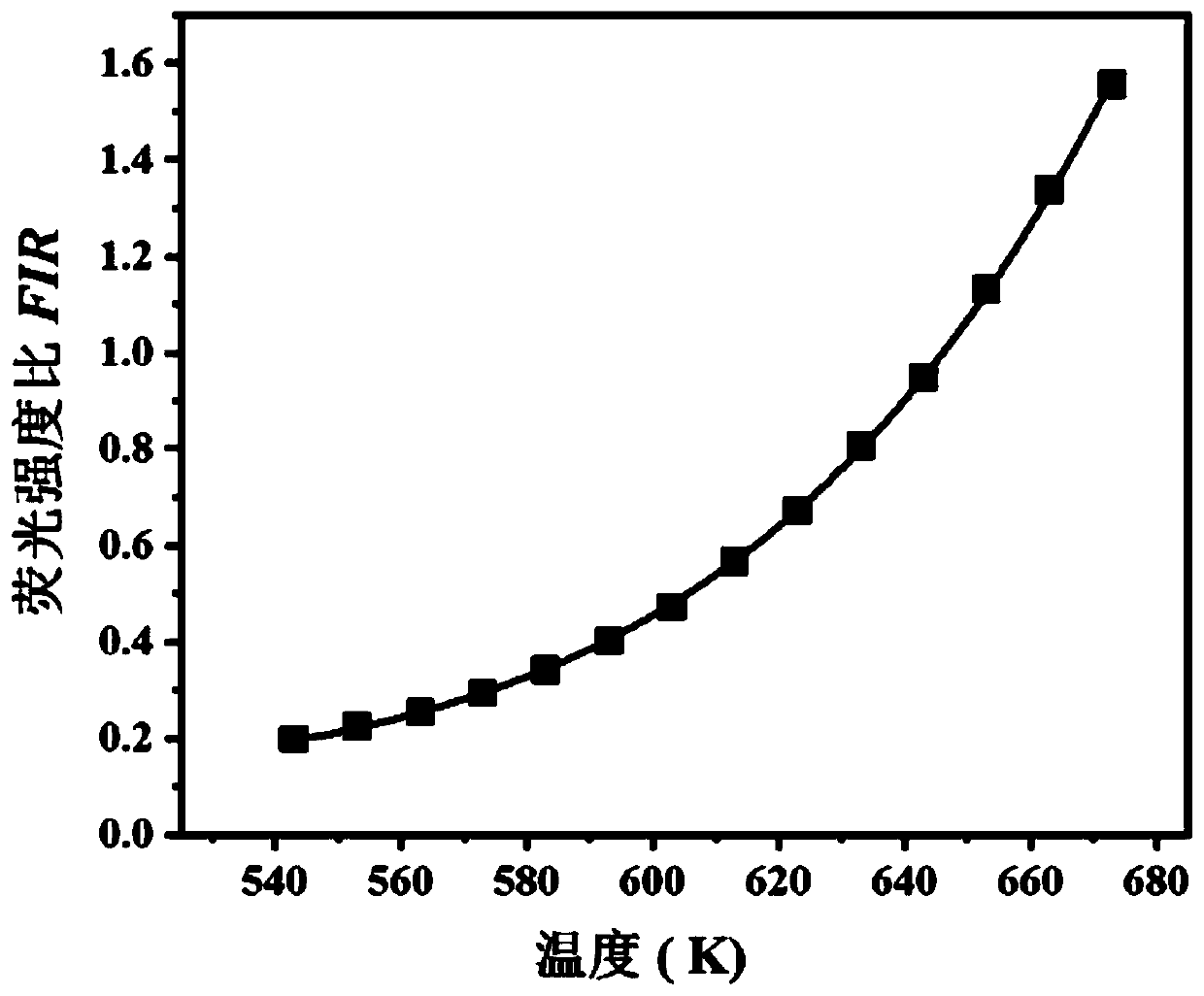

[0029] 2. Put the temperature-sensitive material into the hot and cold stage, use the near-ultraviolet light emitted by the 405nm laser as the excitation light source, and use the integral intensity ratio of the two fluorescent bands of 618nm and 694nm to perform temperature calibration in the temperature range of 543 to 673K, and obtain Temperature calibration curve;

[0030] 3. Place the temperature-sensing material in the environment to be measured, and use the temperature calibration curve to measure the temperature to be measured, that is, complete the temperature measurement method.

[0031] The Eu selected in this embodiment 3+ : AVO 4 / Cr 3+ :...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, Eu 3+ : AVO 4 and Cr 3+ :Al 2 o 3 The preparation methods are all high-temperature solid-phase methods. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, Eu 3+ : AVO 4 with Cr 3+ :Al 2 o 3 Grind into powder, then mix and press into tablets to obtain the temperature-sensitive material. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com