Optical fiber temperature sensor based on nano fluorescent material and measuring system

A nano-fluorescence and optical fiber temperature technology, applied in the field of optical fiber sensing, can solve the problems of low temperature sensitivity and low optical signal intensity, and achieve the effect of simple production, simple structure, and reduction of temperature cross-sensitivity problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

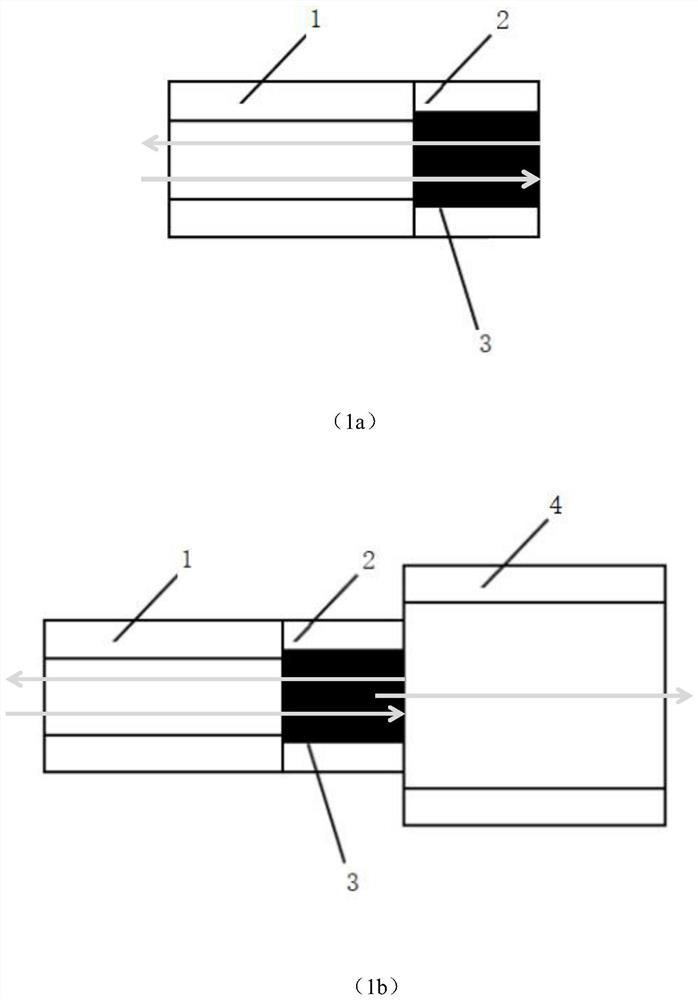

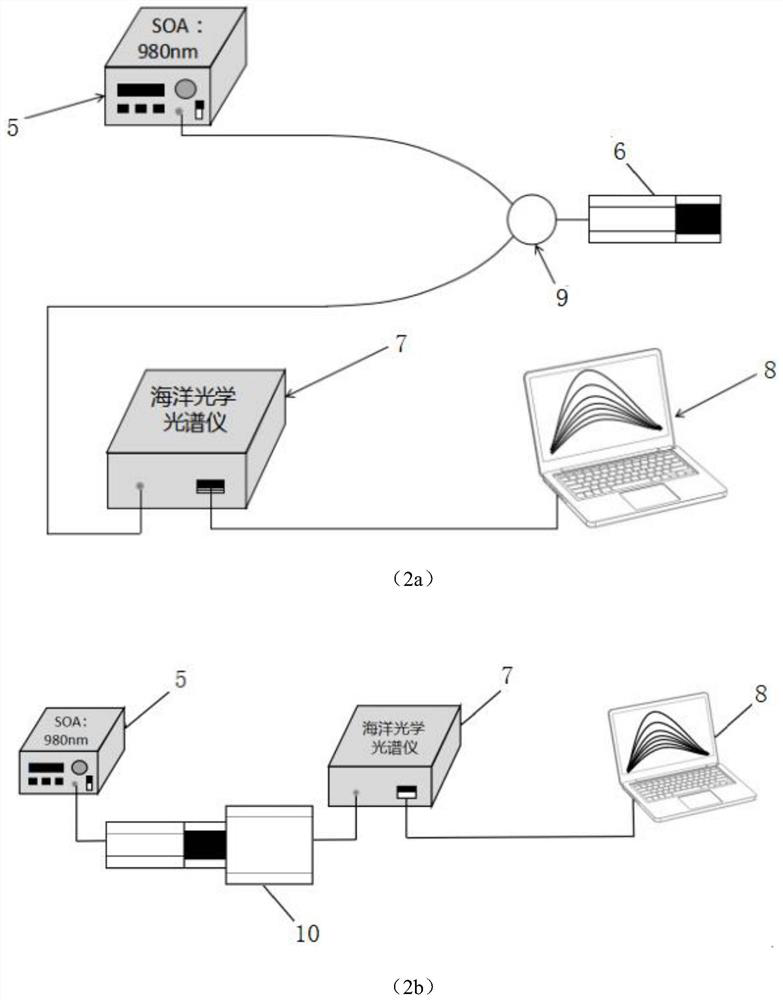

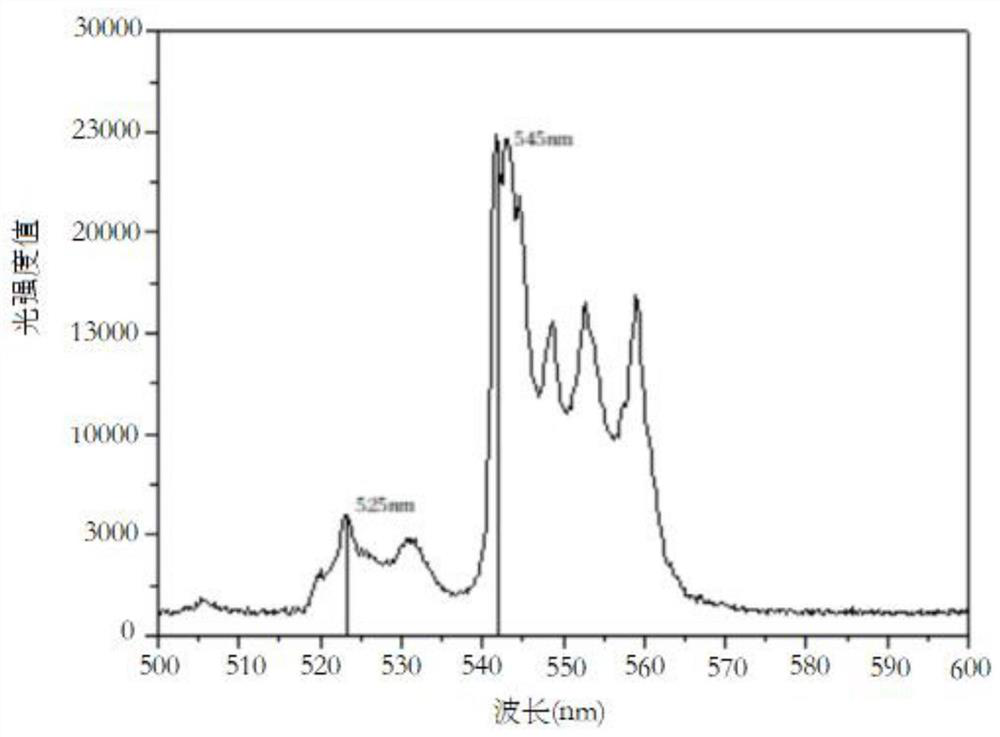

[0039] Such as figure 1 As shown, it is a structural schematic diagram of the optical fiber temperature sensor based on the nano fluorescent material of the present invention. The optical fiber temperature sensor comprises a first multimode optical fiber 1 with a flat end face connected to each other and a hollow core optical fiber 2 , and a hollow core cavity of the hollow core optical fiber 2 is filled with a fluorescent material body 4 . Among them, the hollow-core optical fiber 2 selects an optical fiber with an inner diameter of about 75 microns and an outer diameter of about 125 microns, and the first multimode optical fiber 1 selects an optical fiber with a core diameter of about 62.5 microns and an outer diameter of about 125 microns. The optical fiber temperature sensor structure of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com