Environmental-protection treatment equipment

A technology for environmental protection treatment and equipment, applied in waste heat treatment, grain treatment, lighting and heating equipment, etc., can solve the problems of high energy consumption, complicated process, failure to meet emission standards, etc., and achieve the effect of reasonable structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

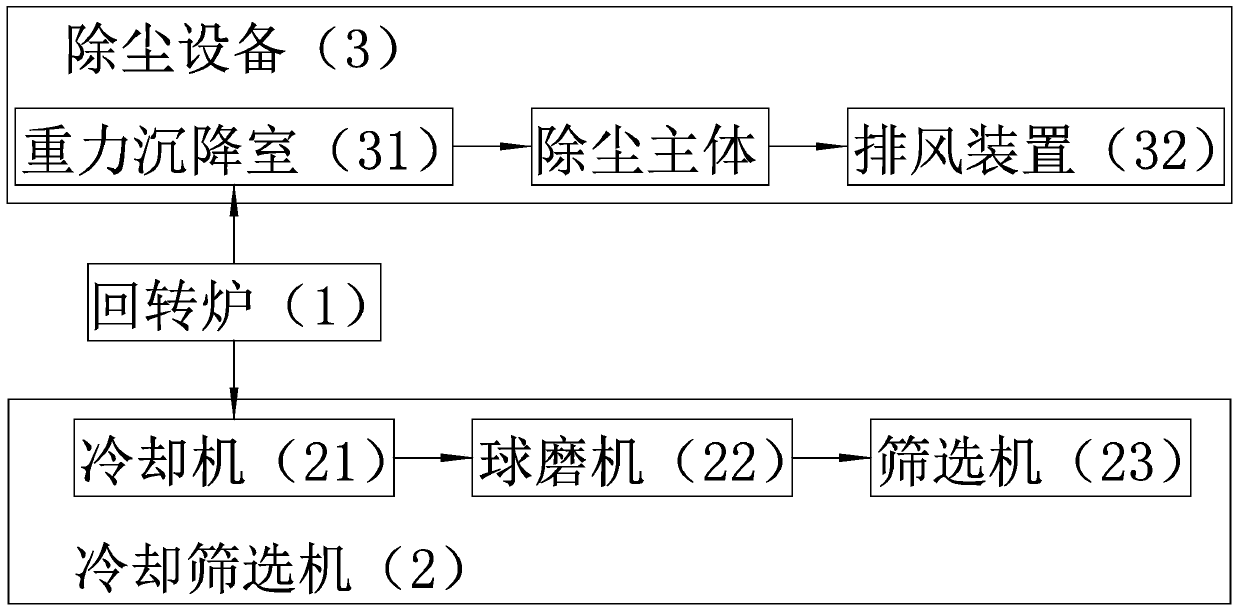

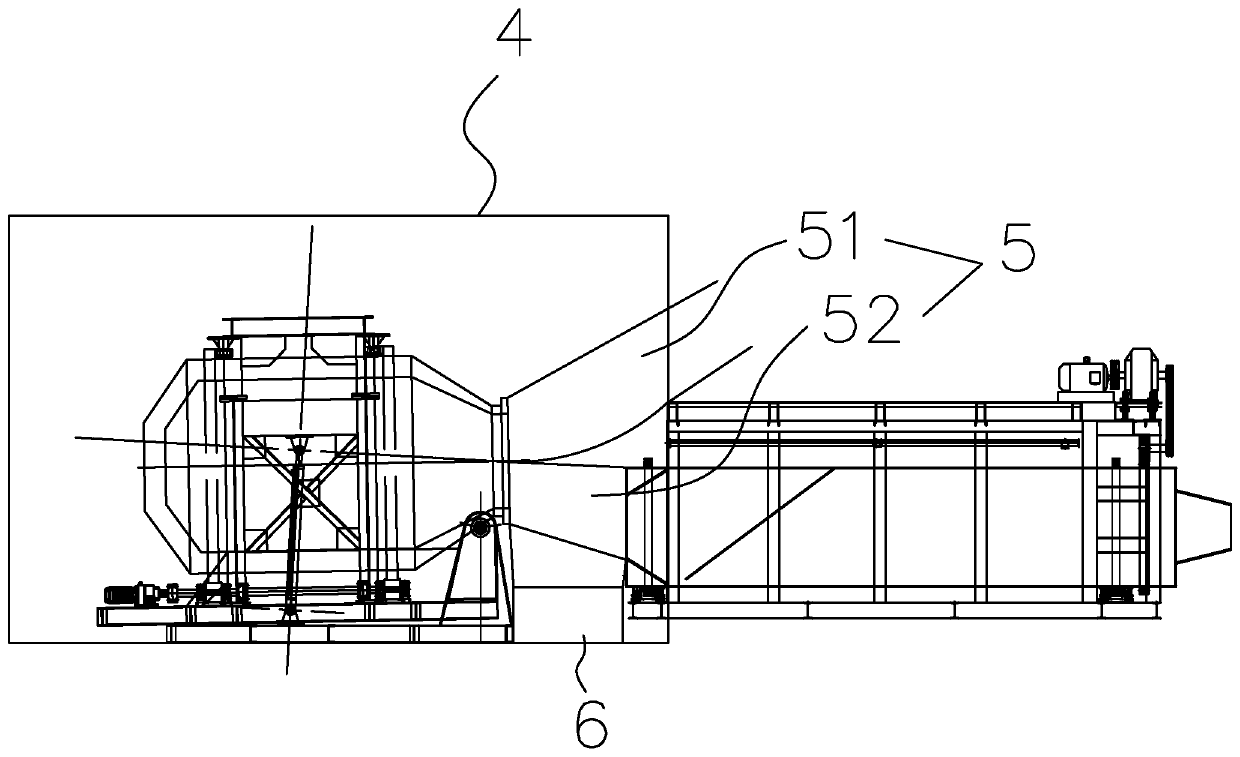

[0030] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a kind of environmental protection processing equipment, including a rotary kiln 1, a cooling screening machine 2 connected to the furnace mouth of the rotary kiln 1, and a dust removal device 3 connected to the exhaust port of the rotary kiln 1. The rotary kiln 1 It is arranged in the airtight building 4, the door is opened on the airtight building 4, and the connecting pipe 5 is arranged between the rotary kiln 1 and the cooling screening machine 2, and the connecting pipe 5 includes the upper and lower layered The feed pipe 51 and the discharge pipe 52, the bottom of the discharge pipe 52 is a mesh structure, the feed pipe 51 and the discharge pipe 52 adopt a downward sloping structure, the feed pipe 51 and the discharge pipe 52 The feed inlet of the feed pipe 51 is inclined downward toward the discharge port, and the discharge port of the feed pipe 51 is arranged at an end close to the rotary kiln 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com