Modification process and device for hot molten copper slag

A hot-melting slag and modification technology, which is applied in hot-melting copper slag modification device and hot-melting copper slag modification technology field, can solve the problem of unsatisfactory iron concentrate grade and recovery rate indicators, difficulty in selling iron concentrate, and inability to Achieving problems such as separation of iron and silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the invention is to provide a hot-melt copper slag modification process to improve the refining precision of iron. Another core of the present invention is to provide a hot-melt copper slag modification device for performing the above-mentioned hot-melt copper slag modification process.

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

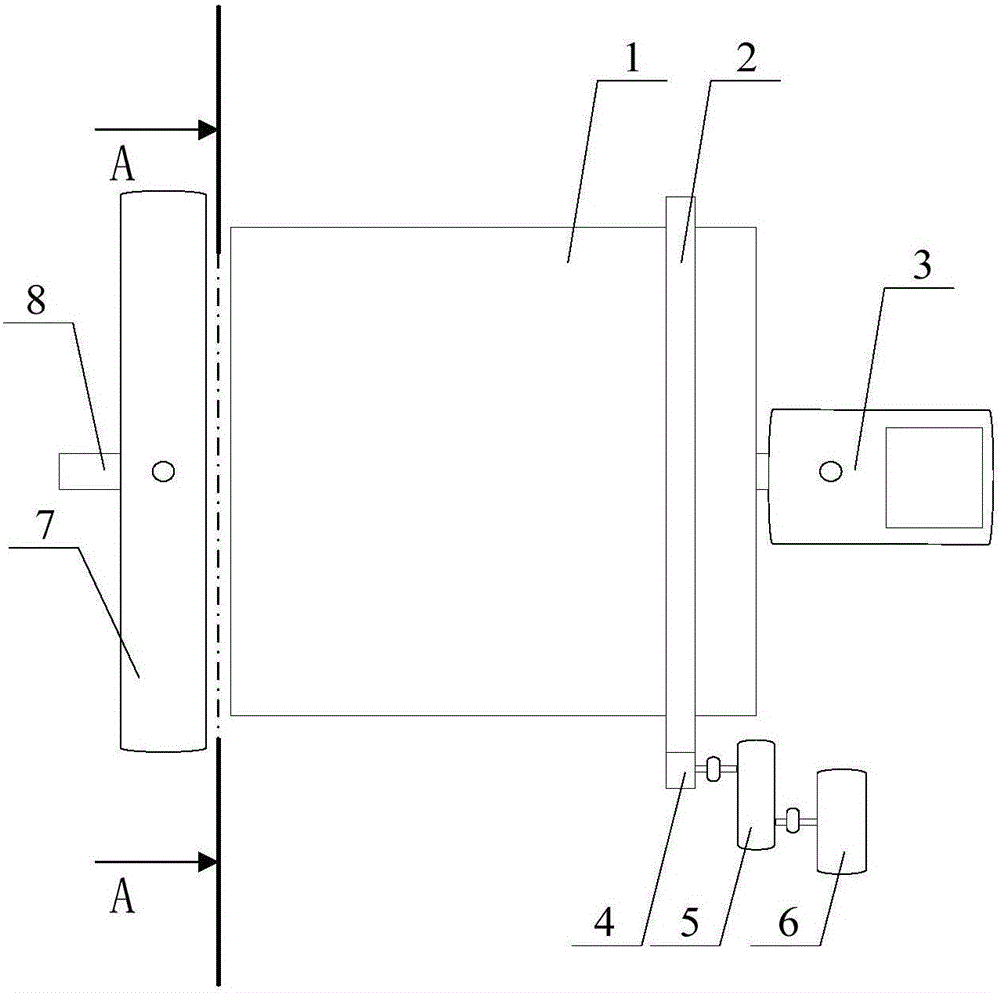

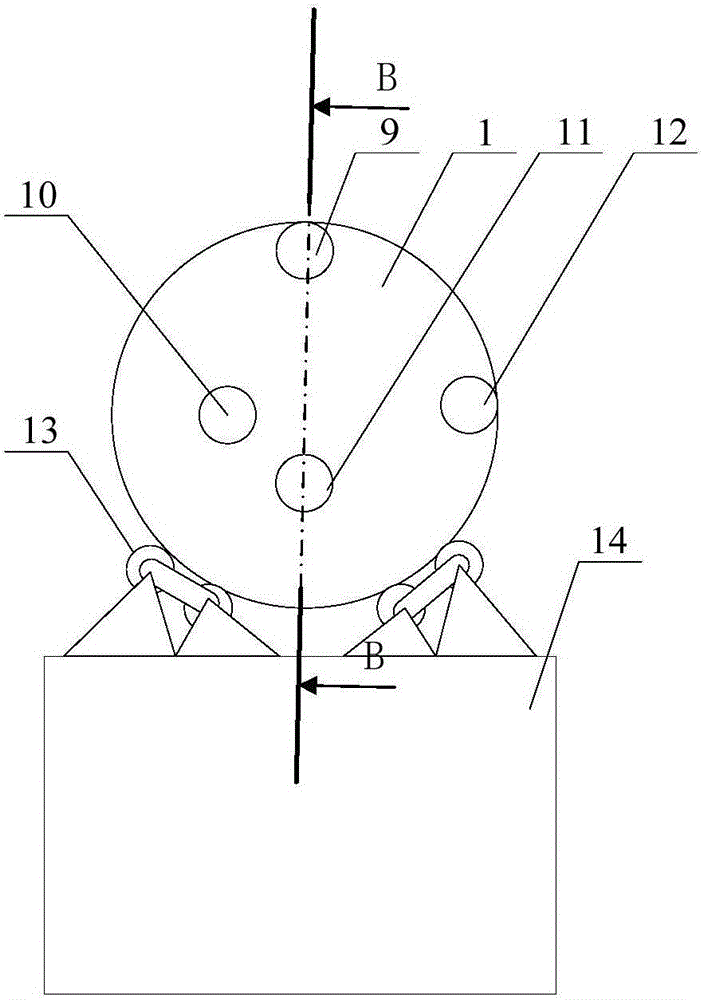

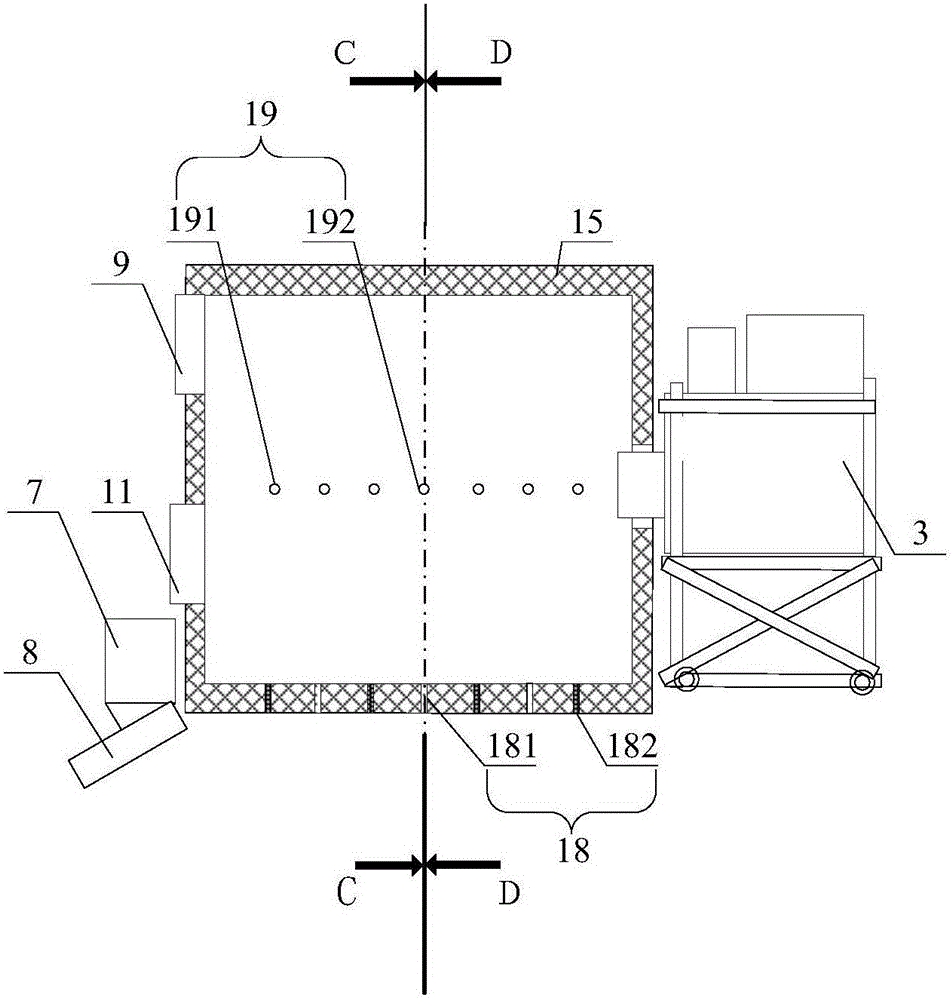

[0032] Please refer to Figure 1 to Figure 7 , in a specific embodiment, the hot melt copper slag modification process provided by the present invention includes the steps of: carrying out oxidation treatment on the slag at the discharge port of the liquid hot molten slag by inputting oxygen; The slag is slowly cooled.

[0033] It can be seen from the above description that in the hot-melt copper slag modification process pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com