Underground mining method for gently-inclined medium-thick or thick phosphorus ore bodies

A technology with a gentle slope and medium thickness and mining methods, which is applied in underground mining, ground mining, mining equipment, etc., and can solve problems such as natural caving of upper layered ore bodies, destruction of upper layered production arrangements, and low strength of phosphate ore bodies , to achieve the effect of reducing the exposed area, improving safety and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] Embodiment 2 Application example of the present invention

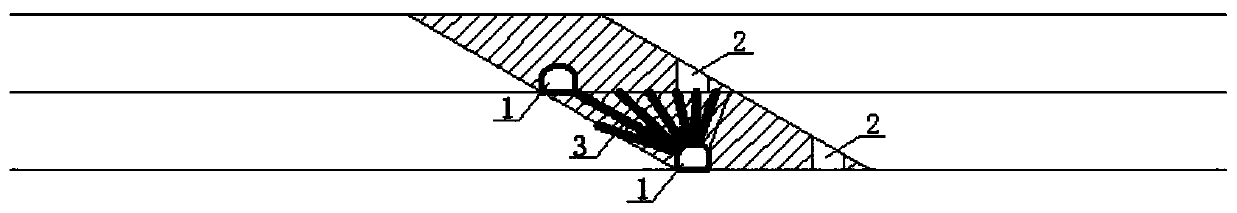

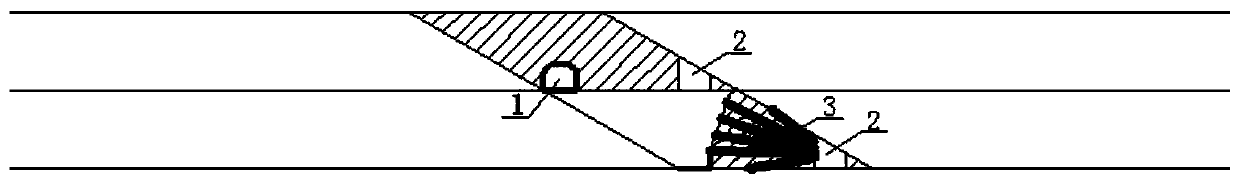

[0032] Take the mining of the N5# ore house at the 490 layer in the south fourth panel area of the 480 middle section of the Shaba soil mine of Guizhou Kailin Group as an example: the ore body dip angle of the mine house is 30-32°, and the ore body thickness is 10-15m, which is a typical gently inclined thickness. The ore body has a geological reserve of 15,985 tons. Before mining, two rock-drilling roadways will be constructed. When mining, the bottom part of the ore body will be mined first, and then the roof part of the ore body will be mined.

[0033] Its mining steps include:

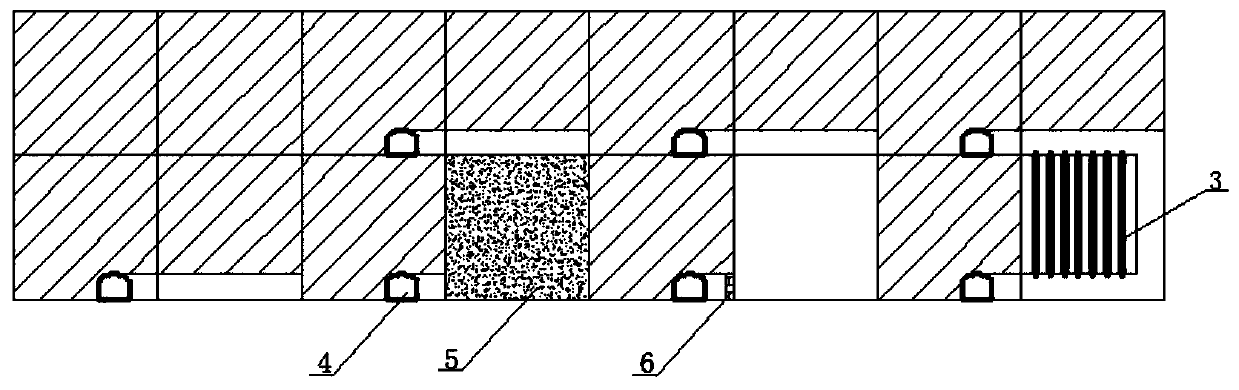

[0034] (1) First, divide the middle section along the ore body tendency, with a height of 100m, and divide the panel along the ore body trend, with a panel length of 600m; divide a layer every 10m along the inclination in the panel; divide a mining area every 20m along the strike in the layer In the stope, a rock-drilling roadway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com