Simple efficient open caisson deviation rectifying method

A high-efficiency technology for caissons, applied in caissons, buildings, infrastructure engineering, etc., can solve problems such as uneven stress on the walls of caissons, unsatisfactory rectification effects, and deflection, so as to reduce sinking resistance and rectify deflection. The effect is good and the operation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

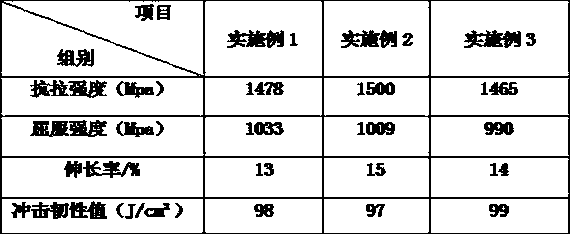

Embodiment 1

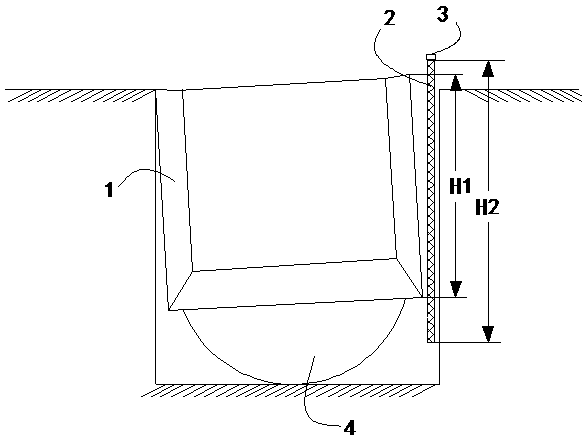

[0027] Such as figure 1 As shown, a simple and efficient caisson correction method of the present embodiment is characterized in that it includes the following steps:

[0028] (1) Select the correction tool: select the Larsen steel sheet pile 2 of the corresponding length according to the depth of the caisson 1;

[0029] (2) Partial excavation: excavate the earthwork at the bottom of the caisson 1 wall on the side where the caisson 1 cannot sink, so as to effectively reduce the frontal resistance of the well wall;

[0030] (3) Deviation correction: on the side where caisson 1 cannot sink, use Larsen steel sheet piles 2 to insert and pull in sequence along the outer side of caisson 1 wall, to loosen and liquefy the soil that hugs caisson 1 wall , reduce the side friction force of the sinking of the caisson 1 wall, and then enable the caisson 1 to sink smoothly under the action of gravity.

[0031] The depth of the caisson 1 is H1, the length of the Larsen steel sheet pile 2 i...

Embodiment 2

[0038] Such as figure 1 As shown, a simple and efficient caisson correction method of the present embodiment is characterized in that it includes the following steps:

[0039] (1) Select the correction tool: select the Larsen steel sheet pile 2 of the corresponding length according to the depth of the caisson 1;

[0040] (2) Partial excavation: excavate the earthwork at the bottom of the caisson 1 wall on the side where the caisson 1 cannot sink, so as to effectively reduce the frontal resistance of the well wall;

[0041] (3) Deviation correction: on the side where caisson 1 cannot sink, use Larsen steel sheet piles 2 to insert and pull in sequence along the outer side of caisson 1 wall, to loosen and liquefy the soil that hugs caisson 1 wall , reduce the side friction force of the sinking of the caisson 1 wall, and then enable the caisson 1 to sink smoothly under the action of gravity.

[0042] The depth of the caisson 1 is H1, the length of the Larsen steel sheet pile 2 i...

Embodiment 3

[0049] Such as figure 1 As shown, a simple and efficient caisson correction method of the present embodiment is characterized in that it includes the following steps:

[0050] (1) Select the correction tool: select the Larsen steel sheet pile 2 of the corresponding length according to the depth of the caisson 1;

[0051] (2) Partial excavation: excavate the earthwork at the bottom of the caisson 1 wall on the side where the caisson 1 cannot sink, so as to effectively reduce the frontal resistance of the well wall;

[0052] (3) Deviation correction: on the side where caisson 1 cannot sink, use Larsen steel sheet piles 2 to insert and pull in sequence along the outer side of caisson 1 wall, to loosen and liquefy the soil that hugs caisson 1 wall , reduce the side friction force of the sinking of the caisson 1 wall, and then enable the caisson 1 to sink smoothly under the action of gravity.

[0053] The depth of the caisson 1 is H1, the length of the Larsen steel sheet pile 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com