Honeycomb plate compounding equipment

A composite equipment, honeycomb panel technology, applied in household appliances, metal processing, other household appliances, etc., can solve problems such as low production efficiency, trimming error, plate conveying direction deviation, etc., to improve production efficiency, ensure accuracy, The effect of reducing the possibility of conveying direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-7 The application is described in further detail.

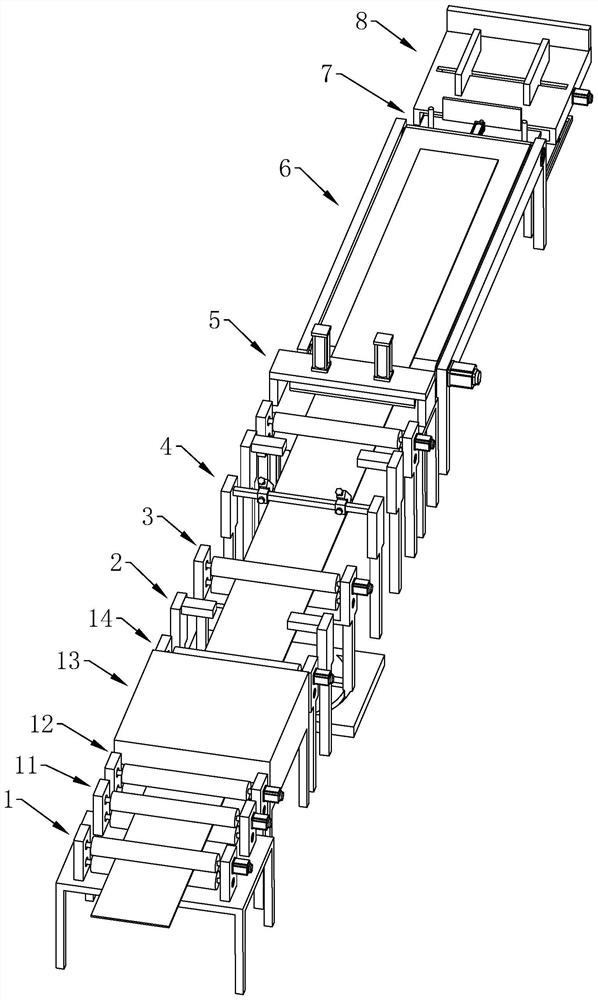

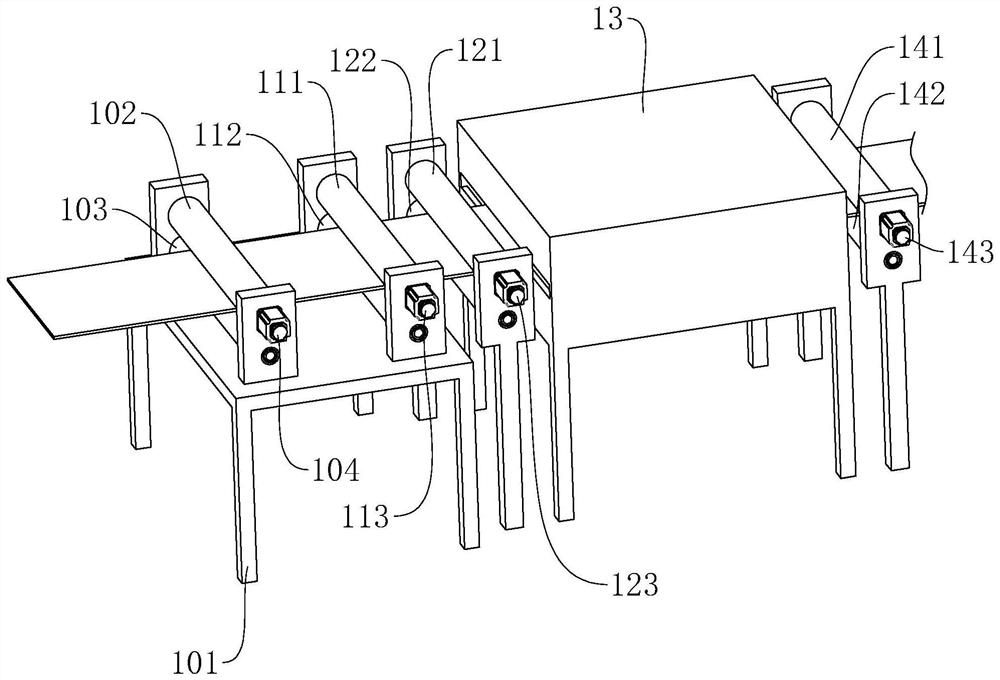

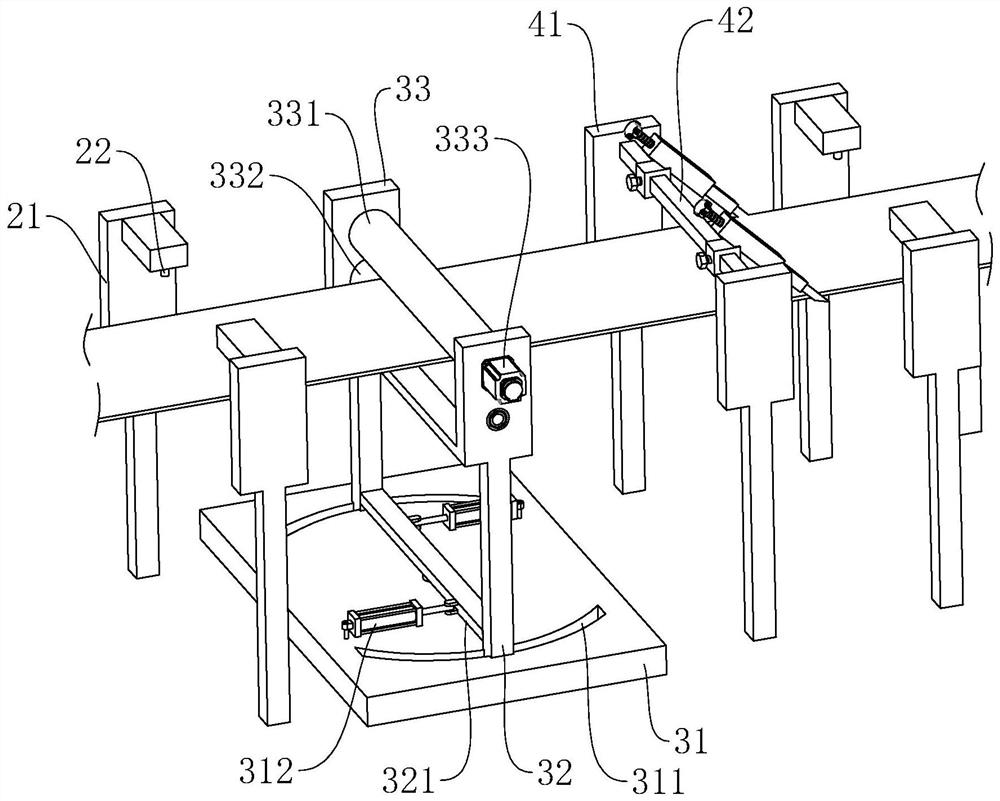

[0036] The embodiment of the present application discloses a composite equipment of honeycomb panels. refer to figure 1 , a honeycomb panel composite equipment includes a heating device 1, a composite device 11, a traction device 12, an oven 13 for stress relief and tempering, a cooling device 14, an induction device 2, a deviation correction device 3, an edge trimming device 4, The induction device 2, the traction device 12, the cutting device 5, the conveying device 6, the alignment device 7 and the collecting device 8, the extruded surface layer, the honeycomb layer and the bottom layer pass through the heating device 1 and the composite device 11 together to form a preliminary The honeycomb panel, the honeycomb panel then passes through several subsequent devices in turn, and the final product is formed after stress relief tempering, trimming, and cutting.

[0037] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com