Pipe-jacking construction monitoring control method

A monitoring control and pipe jacking technology is applied in the field of measurement and deviation correction in the pipe jacking construction of sand and gravel strata, and in the field of pipe jacking construction monitoring and control, to achieve the effect of preventing deviation, strong professionalism and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0021] In conjunction with the accompanying drawings.

[0022] The monitoring and control method for pipe jacking construction includes the following steps:

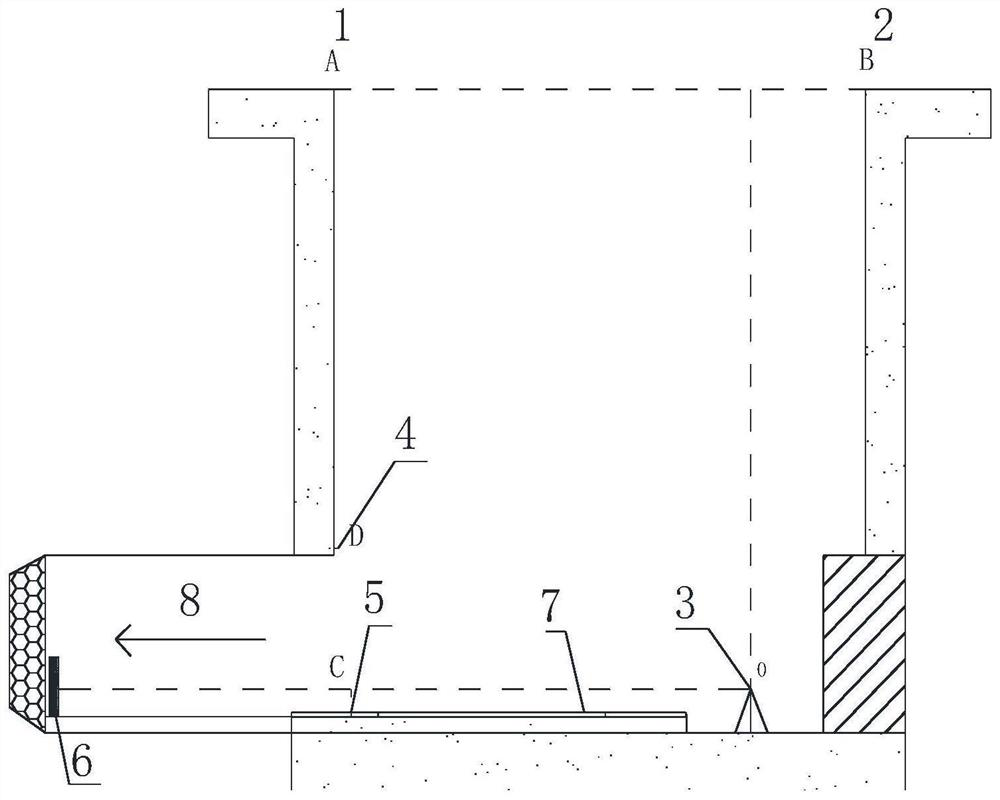

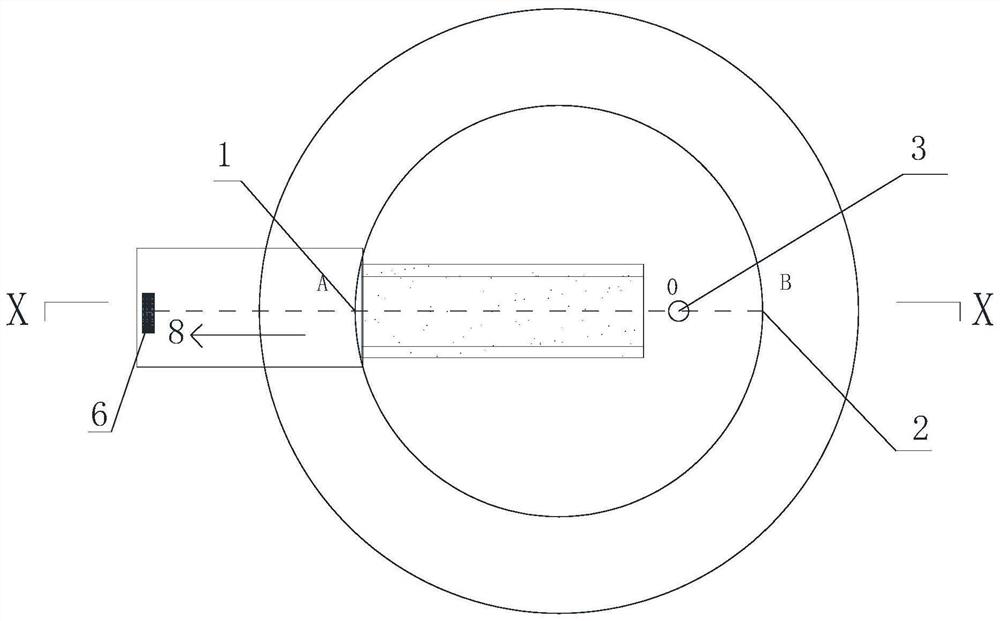

[0023] (1) Preparatory work: Before the pipe jacking construction, use the total station to set the axis datum A point 1 and the axis datum B point 2 on the top surface of the working well according to the pipe jacking design requirements, and the line connecting the two points is the pipe jacking design axis; And use the total station to set the axis direction control point D 4 at the starting hole in the foundation pit of the working well, set the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com