Control system for automatic feeding of casting blank plate material

An automatic feeding and control system technology, applied in the field of feeding systems, can solve problems such as nonlinearity, complexity of automatic correction control objects, difficulty in achieving precision and better adaptability, etc., to ensure continuity and meet the scale of enterprises Production and workload reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the examples and accompanying drawings. The examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

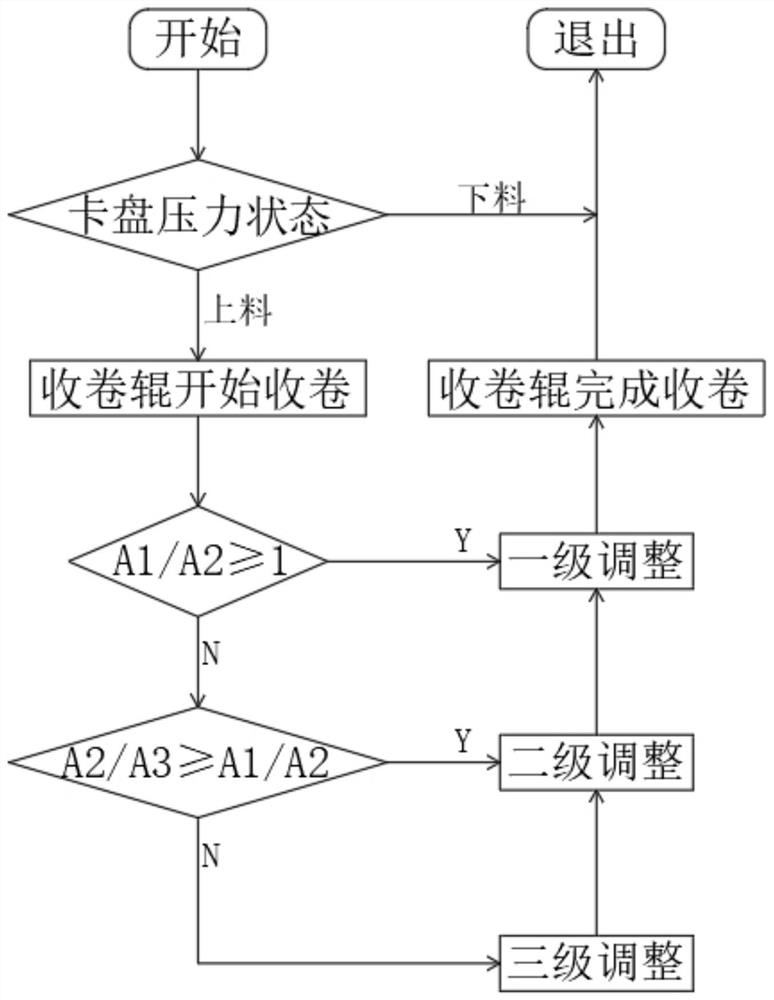

[0013] Such as figure 1 As shown, a control system for automatic feeding of cast slabs includes a sheet conveyor, a chuck, a winding roller, a signal acquisition unit, a control unit and a drive unit, and the chuck is responsible for moving the sheet conveyor The cast slab on the top is grabbed onto the winding roller, and the signal acquisition unit is divided into three groups of signal sources, which are respectively placed on the sheet conveyor belt, on the chuck and at the winding roller, and the signal sources are used to collect Transverse position information data (A1, A2 and A3) of each part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com