Steel bar horizontal stress application deviation rectifying method

A steel bar and horizontal technology, applied in the direction of building reinforcements, building material processing, structural elements, etc., to achieve the effect of good deviation correction, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0041] A method for rectifying the deviation of reinforcement horizontally, comprising the following steps: Figure 7 :

[0042] (1) Obtain parameters such as the spacing of steel bars and the thickness of the protective layer of steel bars by reading the design drawings;

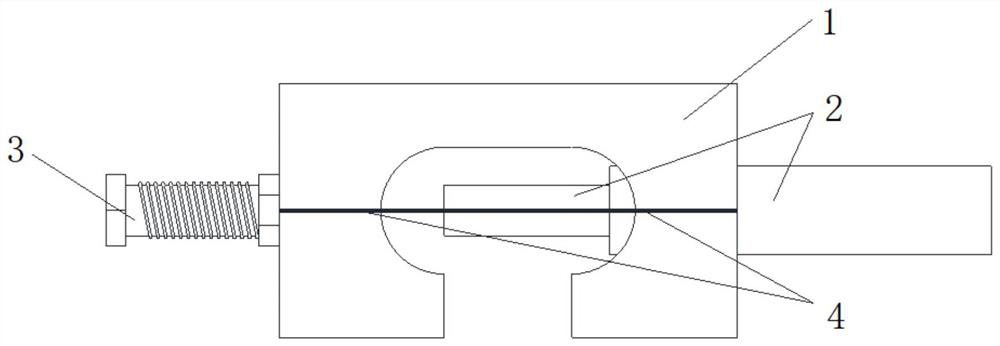

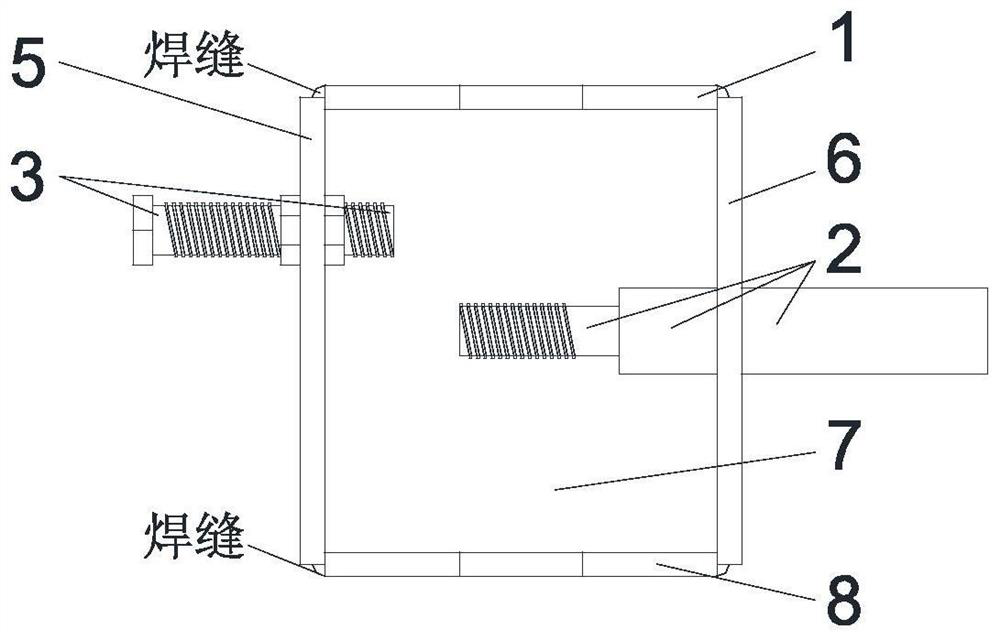

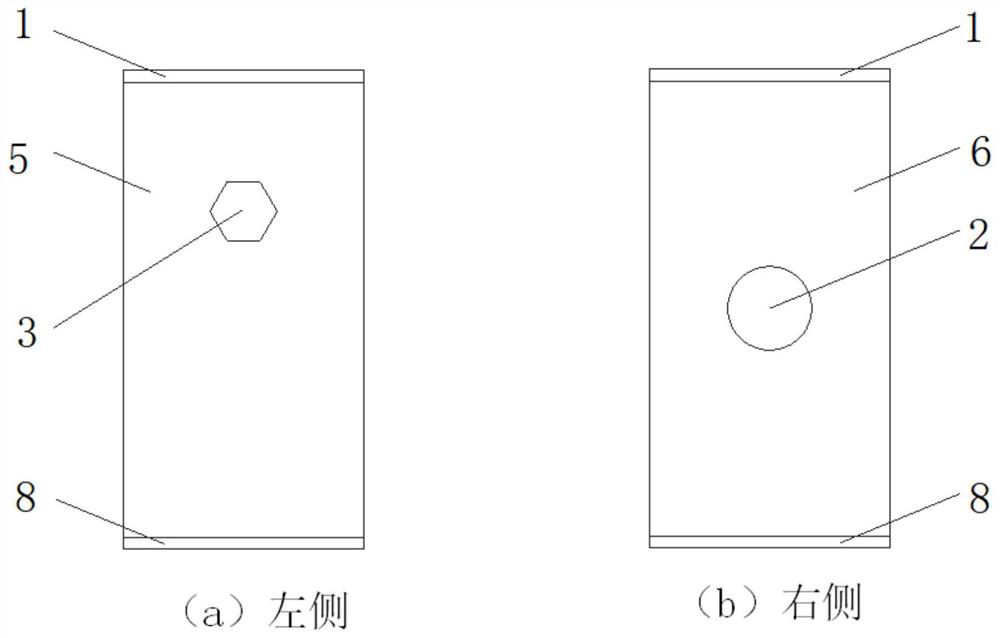

[0043] (2) Install the deviation correction device, such as Figure 1-3 shown;

[0044] (3) Place the auxiliary positioning device on the prefabricated component, and adjust the transparent plate of the device to a horizontal state by adjusting the four support rods 16; the auxiliary positioning device is as follows: Figure 4-5 shown;

[0045] (4) According to the design parameters, draw the horizontal auxiliary positioning line 12 and the longitudinal auxiliary positioning line 13 on the panel through the scale 10 attached to the positioning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com