Automatic mesh belt correcting device

An automatic deviation correction device and correction technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of increasing labor intensity, time-consuming and labor-intensive work, etc., to achieve the elimination of manual intervention, improve operating efficiency, Guarantee the effect of long-term reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

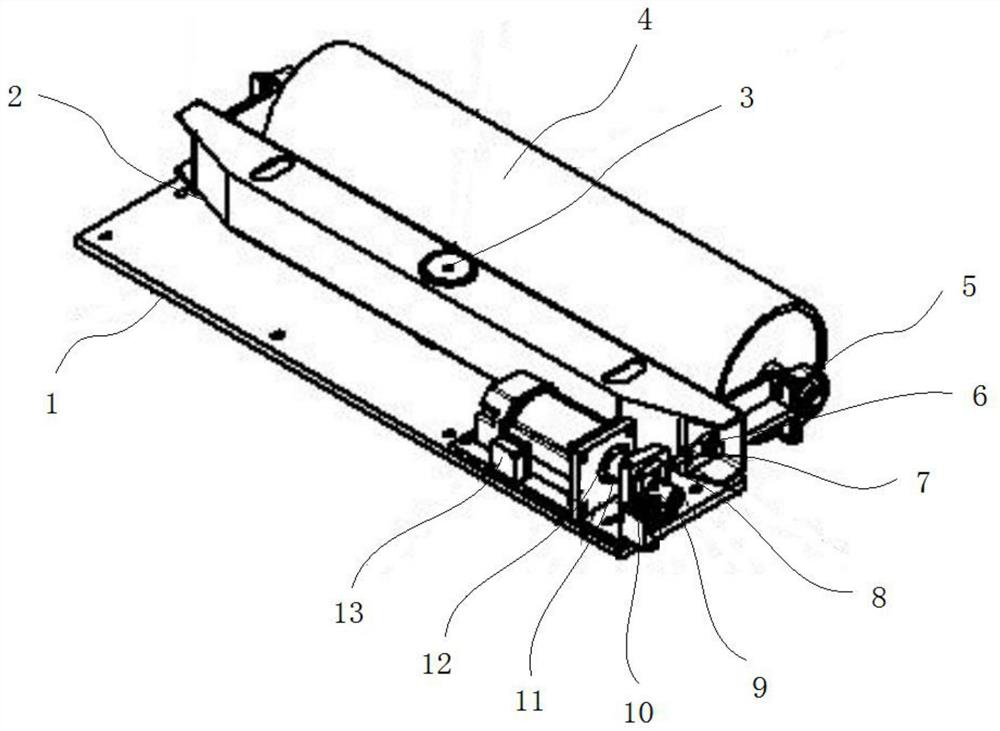

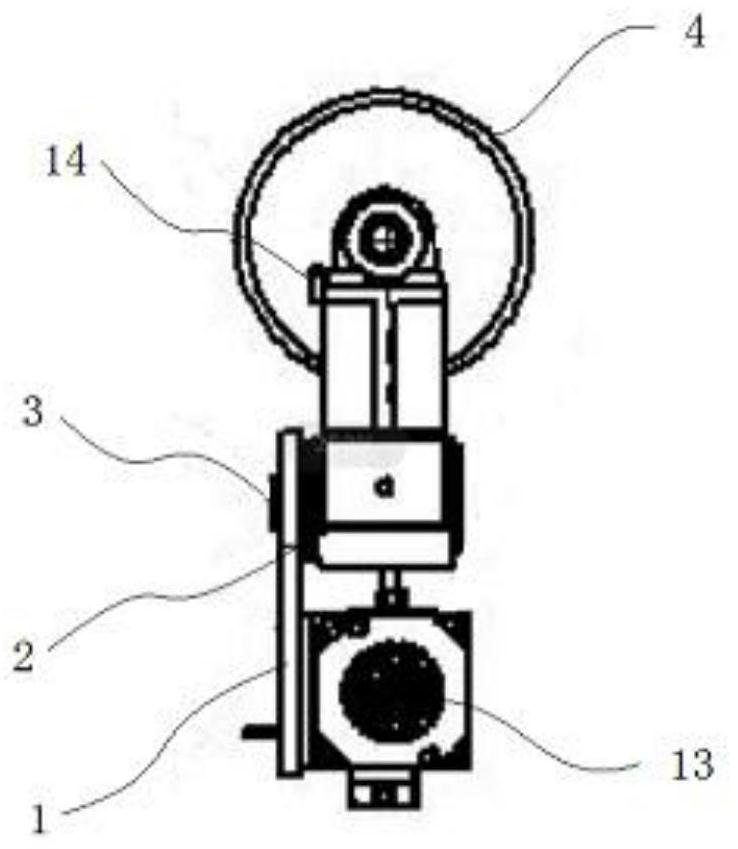

[0033] Please refer to figure 1 , figure 2 ,in, figure 1 A schematic structural view of the first embodiment of the mesh belt automatic deviation correction device provided by the present invention; figure 2 for figure 1 The side view of the mesh belt automatic deviation correction device shown. The mesh belt automatic correction device includes:

[0034] Correction bottom plate 1;

[0035] A deviation correction installation plate 2, the deviation correction installation plate 2 is arranged on the top of the deviation correction bottom plate 1, and a rotation shaft 3 is arranged on the deviation correction installation plate 2;

[0036] The deviation correction wheel 4 is arranged on one side of the deviation correction base plate 1, and the axis center of the deviation correction wheel 4 is provided with a seated bearing 5, and one side of the belt seat bearing 5 is provided with a connecting bearing 6, and the connecting bearing 6 The axis is provided with a connect...

no. 2 example

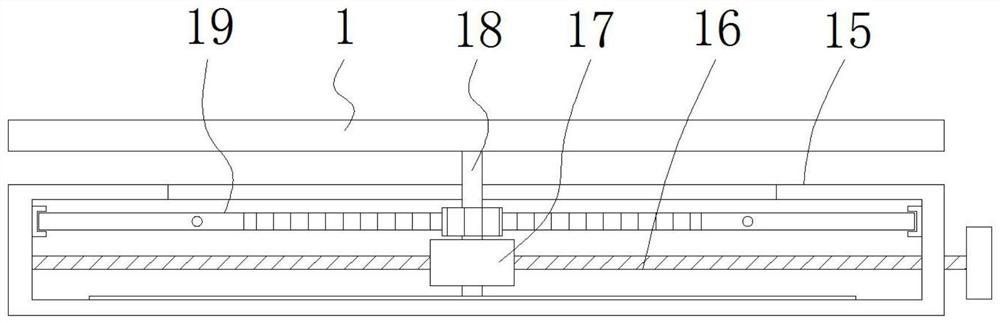

[0054] Please refer to Figure 3-5 , based on the mesh belt automatic deviation correction device provided in the first embodiment of the present application, the second embodiment of the present application proposes another mesh belt automatic deviation correction device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0055] Specifically, the difference of the mesh belt automatic deviation correction device provided by the second embodiment of the present application is that it also includes a movable frame 15, and a screw rod 16 is rotatably connected between the two sides of the inner wall of the movable frame 15, and the The outer surface of the screw rod 16 is threadedly connected with a threaded block 17, one end of the screw rod 16 passes through the movable frame 15 and extends to the outside of the movable frame 15, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com