An Intelligent Wrench Control System

A control system and wrench technology, applied in the direction of wrenches, manufacturing tools, power tools, etc., can solve the problems of lack of precision tightening tools, inability to ensure assembly quality, no monitoring and tracking, etc., to achieve accurate tightening torque, low indication accuracy, The effect of high sampling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

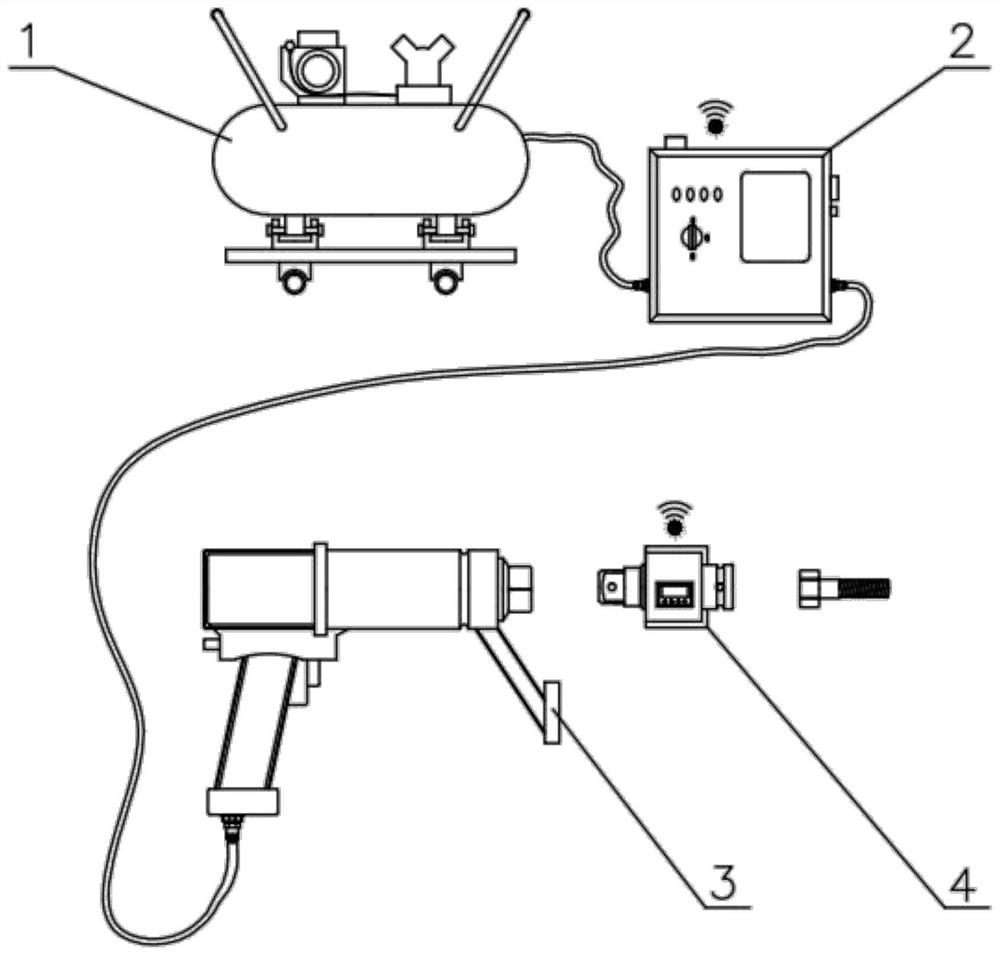

[0055] Pneumatic power source + pneumatic power wrench

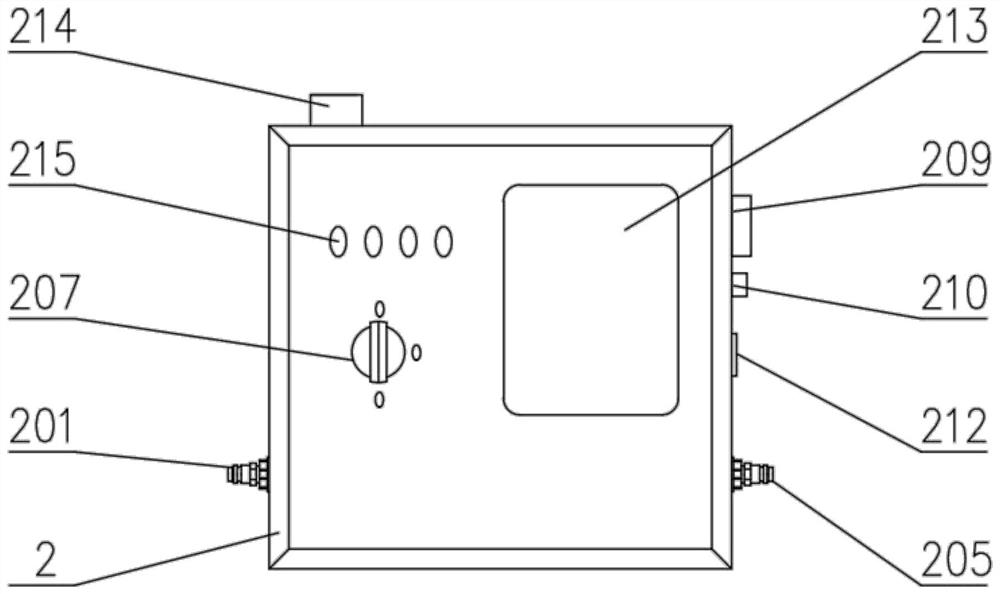

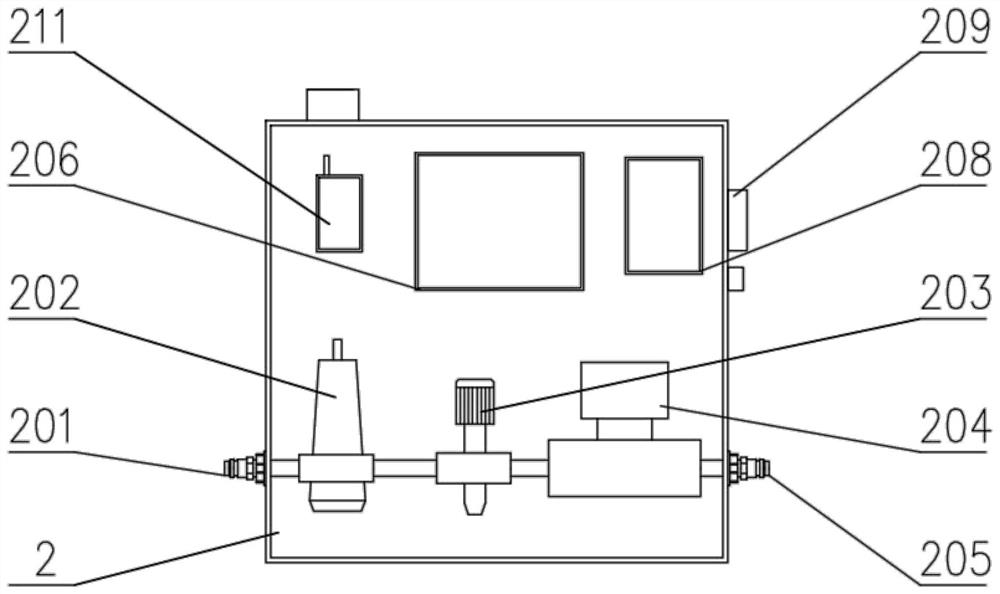

[0056] Preparations: Connect the output port of the power source to the power input port of the torque controller, and then connect the power output port of the torque controller to the power input port of the pneumatic power wrench. Since both ends are standard 1 / 2-inch pipe thread quick connectors, so Easy and fast to connect. Select the corresponding torque sleeve according to the specifications of the target fastener and install it in the chuck of the pneumatic torque wrench, then turn on the power supply of the torque measurement feedback sleeve, and at the same time turn on the power supply of the torque controller, check the status information on the display screen, and input the pressure value to ensure The input pressure value is normal, the power supply of the torque controller is normal, the communication status of the torque measurement feedback sleeve is normal, the indicator light flashes normally, and ther...

Embodiment 2

[0060] Hydraulic power source + hydraulic power wrench

[0061] Preparations: Connect the output port of the power pump to the power input port of the torque controller, and then connect the power output port of the torque controller to the power input port of the hydraulic power wrench. Since both ends are standard 1 / 2-inch hydraulic quick connectors, the connection Simple and fast. Select the corresponding torque socket according to the specification of the target fastener and install it in the chuck of the power wrench, then turn on the power supply of the torque measurement feedback socket, and at the same time turn on the power supply of the torque controller, check the status information on the display screen, and input the power value to ensure the input The power value is normal, the power supply of the torque controller is normal, the communication status of the torque measurement feedback sleeve is normal, the indicator light flashes normally, and there are no other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com