Motorcycle throttle body inclined hole machining device

A technology for a throttle body and a processing device, which is used in positioning devices, clamping devices, metal processing equipment, etc., can solve the problems of difficult control of position accuracy, movement of parts, and small positioning benchmarks, so as to improve tooling efficiency and improve processing. Accuracy, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

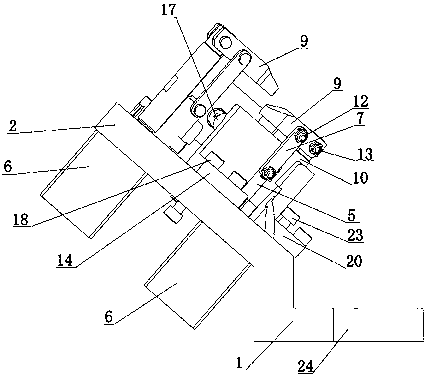

[0022] Such as Figure 1~5 As shown, a motorcycle throttle body oblique hole processing device, which includes a fixture body, a fixture limit unit arranged on the fixture body, a fixture pressing unit and a limit block unit, and the positioning of the parts is made by the fixture limit unit. The surface is tightly attached to the positioning surface of the clamp limit unit without gaps, the parts are pressed down by the clamp pressing unit, and the forward and backward movement of the parts is restricted by the limit block unit.

[0023] The fixture body includes a base plate 1 and a slant plate 2, the slant plate 2 and the base plate 1 are integrally formed, the slant plate 2 is fixed on the top of the base plate 1, and the angle formed by the slant plate 2 and the base plate 1 can make the tool an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com