Salvia extract nanocrystal self-stabilizing pickering emulsion and preparation method thereof

An extract and nanocrystal technology, applied in the field of Salvia miltiorrhiza extract nanocrystal self-stabilizing Pickering emulsion and its preparation, can solve the problems of complex extract components, limiting the drug-carrying capacity of the emulsion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

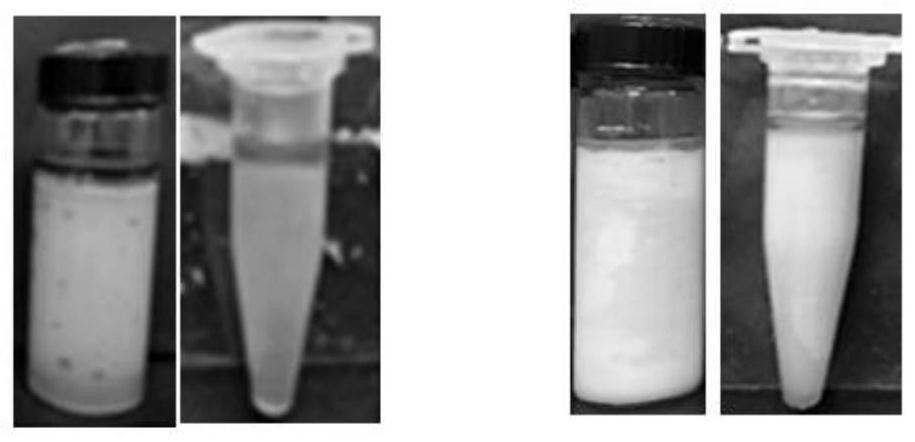

[0041] The preparation method of the Danshen extract nanocrystal self-stabilizing Pickering emulsion of the present invention comprises the following steps:

[0042] A. Prepare the primary suspension: dissolve the salvia miltiorrhiza extract in an organic solvent, add it into water with a pH value of 9-13 under stirring, continue heating and stirring to evaporate the organic solvent, and obtain the primary suspension A;

[0043] B. Preparation of nanocrystal suspension: Homogenize the primary suspension A obtained in step A to obtain nanocrystal suspension B through high-pressure homogenization;

[0044] C. Preparation of nanocrystalline self-stabilizing Pickering emulsion: the nanocrystalline suspension B obtained in step B is mixed with oil phase macrogol glycerol oleate, and homogenized under high pressure to obtain nanocrystalline self-stabilizing Pickering emulsion of Salvia miltiorrhiza extract.

[0045] In the above-mentioned preparation method:

[0046] The organic so...

Embodiment 1

[0140] The preparation method of embodiment 1 salvia miltiorrhiza extract nanocrystal self-stabilizing Pickering emulsion, comprises the following steps:

[0141] (1) Weigh 80 mg of the salvia miltiorrhiza extract raw material, add it to 5 mL of ethanol, shake it in a constant temperature water bath at 50 ° C for 4 hours, pour it into 40 ml of pure water with an initial pH value of 9, stir and evaporate the ethanol at 60 ° C, and obtain the primary suspension A ;

[0142] (2) The primary suspension A is homogeneously circulated 10 times under the condition of 600bar to prepare the nanocrystal suspension B;

[0143] (3) Mix the prepared nanocrystal suspension B with 4ml of the mixed oil phase (baldwood volatile oil: polyethylene glycol oleic acid glyceride = 2:1), and then use a high-pressure homogenizer to circulate under the condition of 600bar 10 times, a self-stable Pickering emulsion formulation can be prepared.

[0144] The particle size was detected by photon correlati...

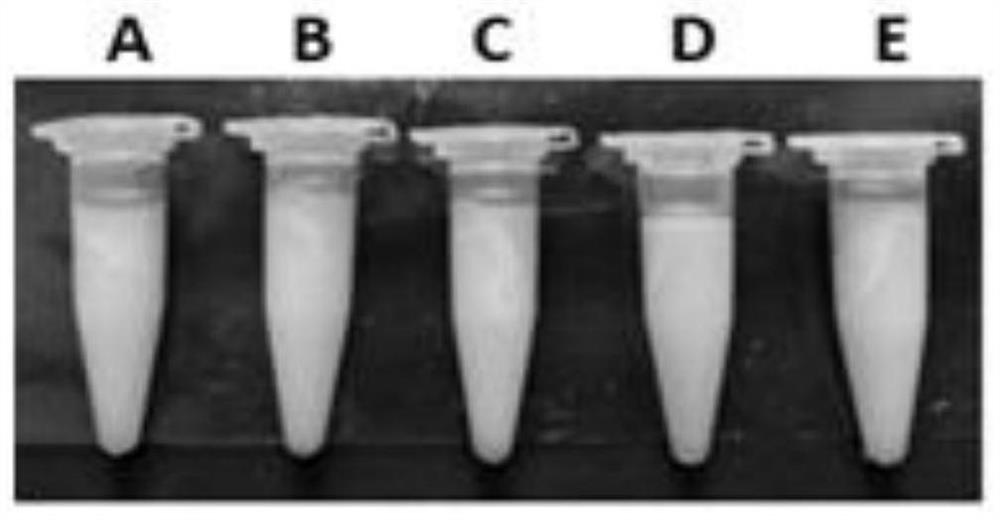

Embodiment 2

[0145] The preparation method of embodiment 2 Danshen extract nanocrystal self-stabilizing Pickering emulsion, comprises the following steps:

[0146] (1) Weigh 160mg of salvia miltiorrhiza extract raw material drug, add 5ml of acetone: ethanol (1:1) mixed solvent, oscillate in a constant temperature water bath at 50°C for 4h, inject into 40ml of pure water with an initial pH value of 9, stir and evaporate at 60°C Remove the organic solvent to obtain primary suspension A;

[0147] (2) The primary suspension A is homogeneously circulated 20 times under the condition of 800bar to prepare the nanocrystal suspension B;

[0148] (3) Mix the prepared nanocrystal suspension B with 4ml of mixed oil phase (balm balm volatile oil: macrogol glycerol oleate=1:2), and then use a high-pressure homogenizer to circulate at 800bar After 20 times, a self-stable Pickering emulsion formulation can be obtained.

[0149] The particle size was detected by photon correlation spectroscopy (PCS), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com