Hollow carbon sphere/molybdenum disulfide bipolar composite material and preparation method and application thereof

A technology of molybdenum disulfide and hollow carbon spheres, which is applied in the field of materials, can solve the problems of battery capacity reduction and achieve the effect of simple preparation method and good initial charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of hollow carbon spheres / molybdenum disulfide (HCS / MoS 2 ) bipolar material, its preparation method is as follows:

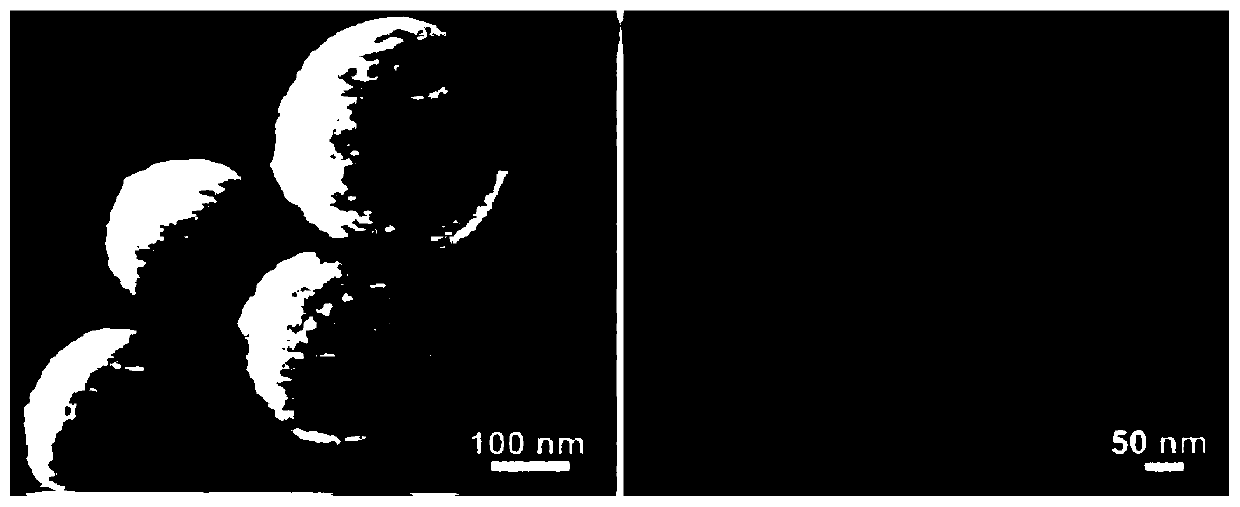

[0039](1) First mix 80mL of deionized water and 80mL of DMF, then add 5mL of cetyltrimethylammonium bromide solution (20mg / mL) and 6.4mL of sodium hydroxide solution (6mg / mL) under ultrasonic conditions ), stir well, then add 1.2mL tetraethyl silicate and dissolve in 12mL methanol solution, stir well and then filter with suction, take the solid phase, wash and dry to obtain SiO 2 Template ball (field emission scanning electron microscope picture as figure 1 shown).

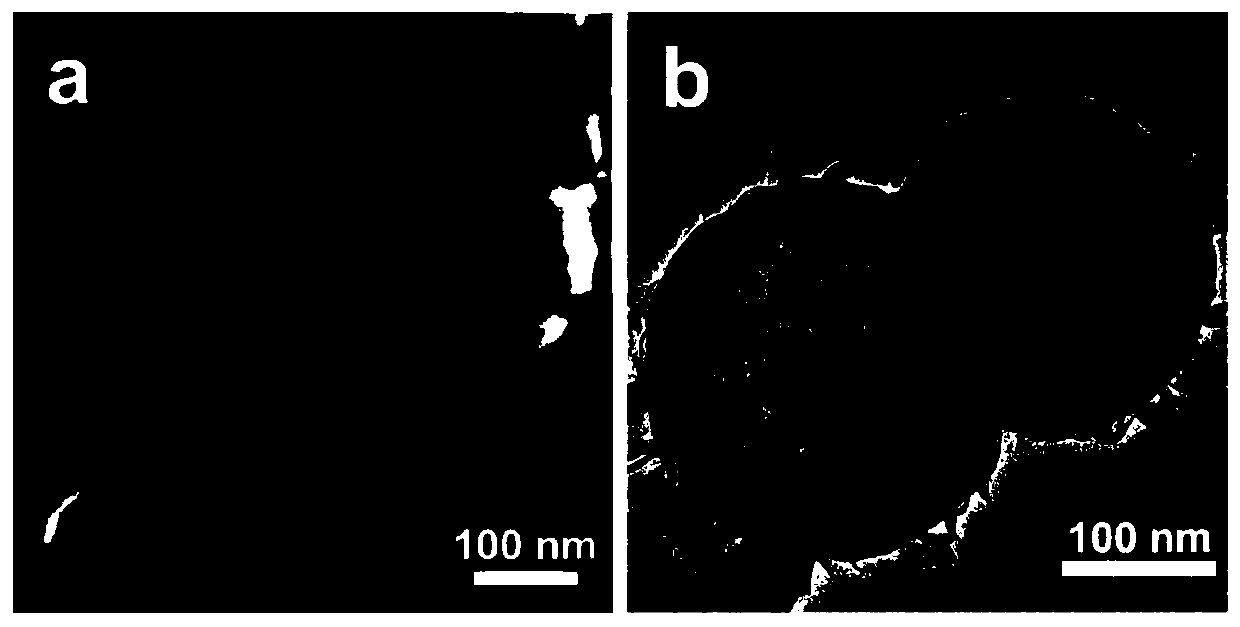

[0040] (2) At first, the silica sphere template sphere (SiO2) prepared in step (1) 2 ) as a template, 60mg SiO 2 The spheres were evenly dispersed in 400mL Tris buffer solution (10mM, pH=8.5) and ultrasonically dispersed, then 180mg of dopamine hydrochloride was added to the solution, and after stirring evenly, the solid phase was taken to obtain a precursor after washing and ...

Embodiment 2

[0044] Preparation of hollow carbon spheres / molybdenum disulfide (HCS / MoS 2 ) bipolar material, its preparation method is as follows:

[0045] (1) First mix 160mL deionized water and 80mL DMF, then add 5mL cetyltrimethylammonium bromide solution (15mg / mL) and 6.4mL sodium hydroxide solution (8mg / mL) under ultrasonic conditions ), stir well and then add 1.2mL tetraethyl silicate to dissolve in 4mL methanol solution, stir well and then filter with suction, take the solid phase and wash and dry to obtain silica template spheres (SiO 2 template ball).

[0046] (2) 60mg SiO 2 The template spheres were evenly dispersed in 400mL Tris buffer solution (5mM, pH=8.5) and ultrasonically dispersed, then 30mg of dopamine hydrochloride was added to the solution, after stirring evenly, the solid phase was taken and washed and dried to obtain a hollow carbon sphere precursor. It is then subjected to a reducing gas (H 2 :Ar=10:90v:v) with a heating rate of 2°C / min, heat treatment at 700°C f...

Embodiment 3

[0049] Preparation of hollow carbon spheres / molybdenum disulfide (HCS / MoS 2 ) bipolar material, its preparation method is as follows:

[0050] (1) First mix 100mL deionized water and 80mL DMF, then add 5mL cetyltrimethylammonium bromide solution (18mg / mL) and 6.4mL sodium hydroxide solution (7mg / mL) under ultrasonic conditions ), stir well, then add 0.4mL tetraethyl silicate and dissolve in 10mL methanol solution, stir well and then filter with suction, take the solid phase and wash and dry to obtain silica template spheres (SiO 2 template ball).

[0051] (2) 60mg SiO 2 The template spheres were uniformly dispersed in 400mL Tris buffer solution (8mM, pH=8.5) and ultrasonically dispersed, then 100mg of dopamine hydrochloride was added to the solution, after stirring evenly, the solid phase was taken, washed and dried to obtain a hollow carbon sphere precursor, It is then subjected to a reducing gas (H 2 :Ar=10:90v:v) with a heating rate of 2°C / min, heat treatment at 700°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com