A joint automatic calibration method and device for a robot visual servo system

A technology of robot vision and servo system, applied in the computer field, can solve problems such as global optimization without consideration of system error, error analysis and optimization, and increased debugging difficulty, so as to achieve the effect of eliminating manual operation, realizing system error and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

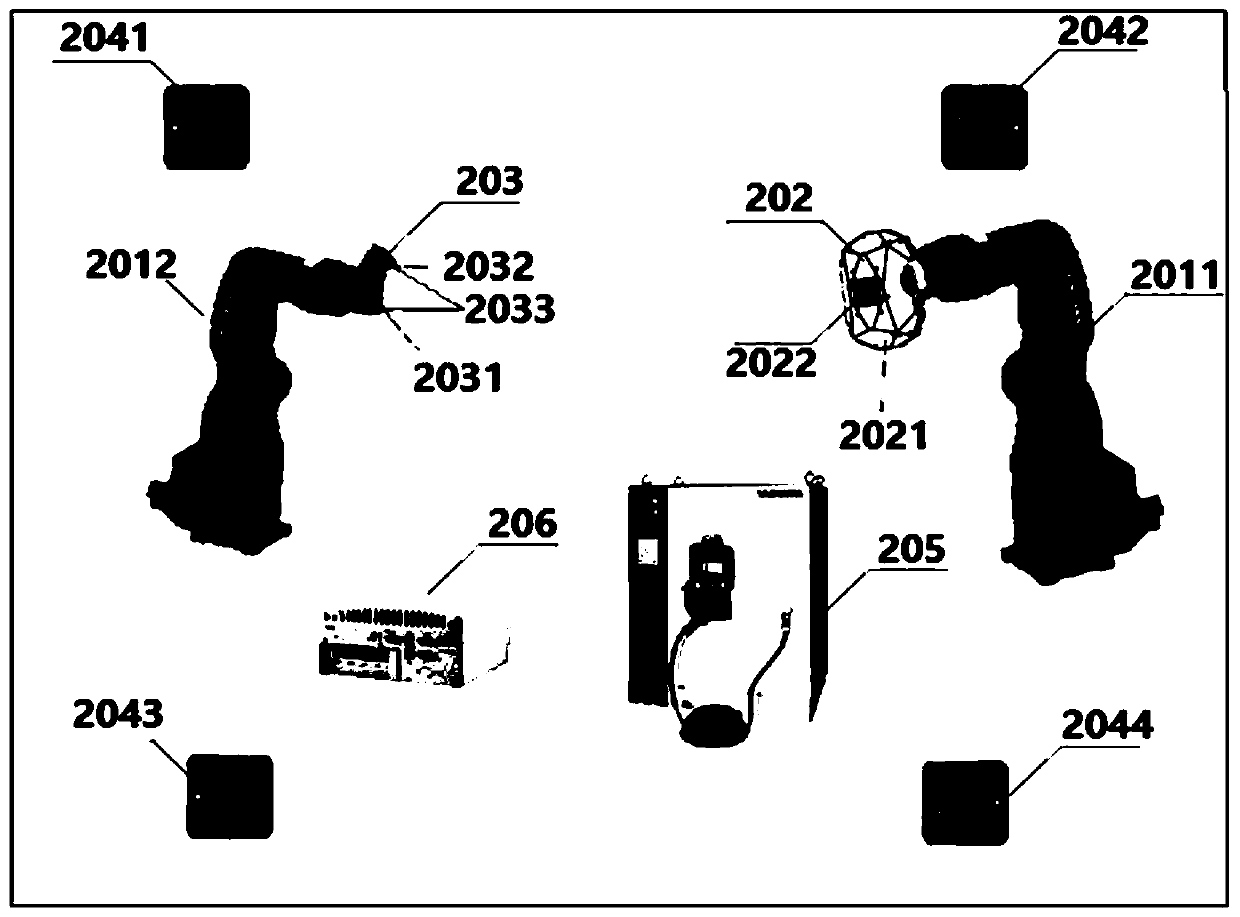

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

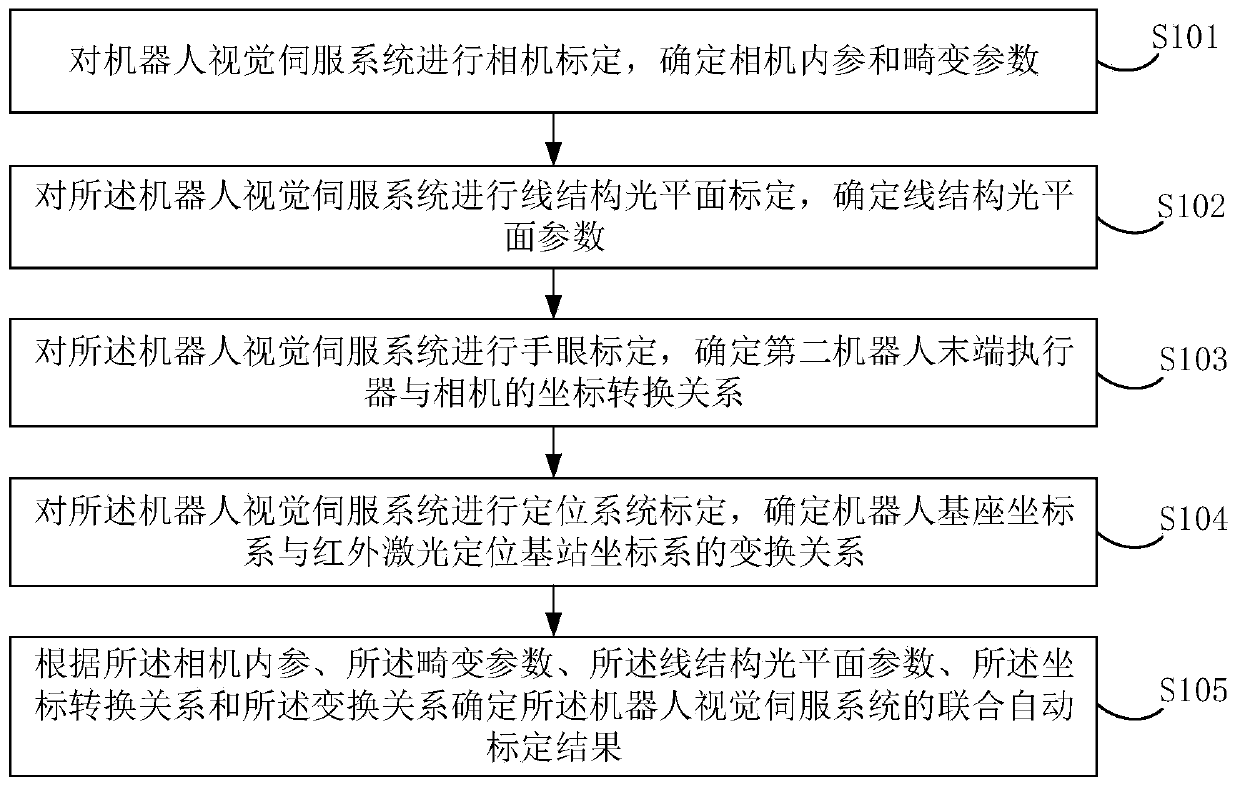

[0037] figure 1 It shows a schematic flowchart of a joint automatic calibration method for a robot visual servo system provided in this embodiment, including:

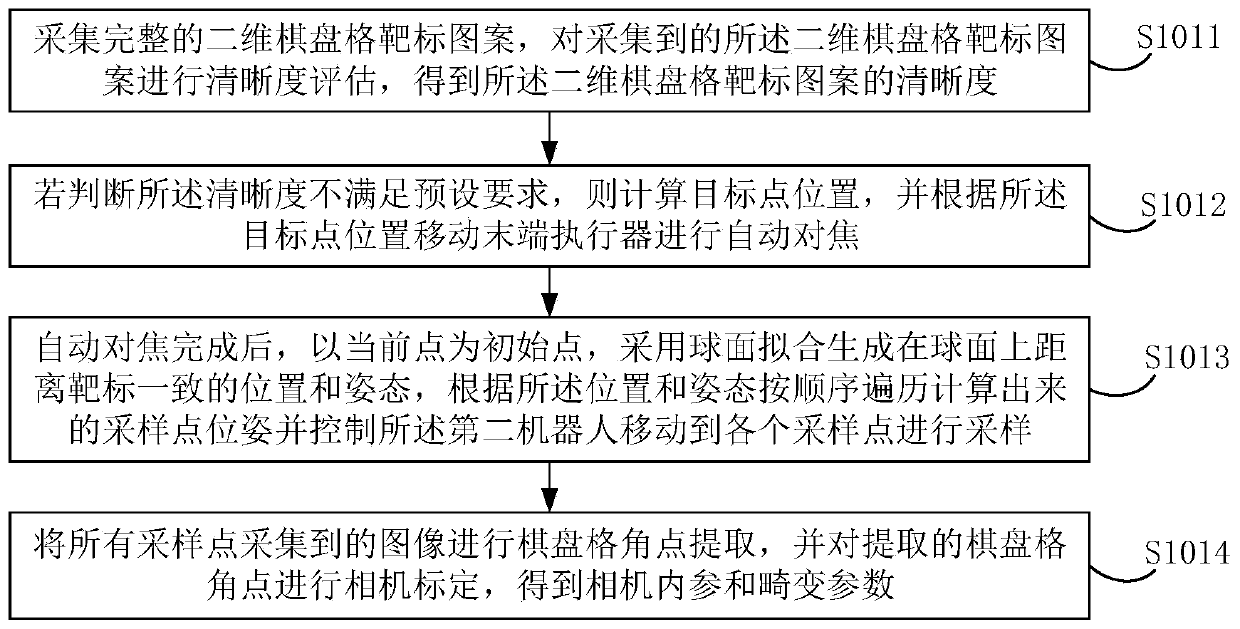

[0038] S101. Carry out camera calibration for the robot visual servo system, and determine camera internal parameters and distortion parameters.

[0039] Specifically, the image acquisition requirements for camera calibration are the simplest, as long as the camera can capture a complete and clear target pattern, the acquisition conditions can be considered satisfied. Therefore, it is only necessary to fix the position of the calibration object in advance, calculate a series of positions and attitudes suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com