Equipment for evaporating plated terbium or dysprosium on magnetic material surface

A magnetic material, magnetic material technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating and other directions, can solve the problems of unenvironmental protection, product instability, etc., to improve production efficiency and improve process stability and repeatability, excellent film density and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0027] In order to facilitate the unified view of the various reference signs in the drawings of the specification, the reference signs appearing in the drawings of the specification are described as follows:

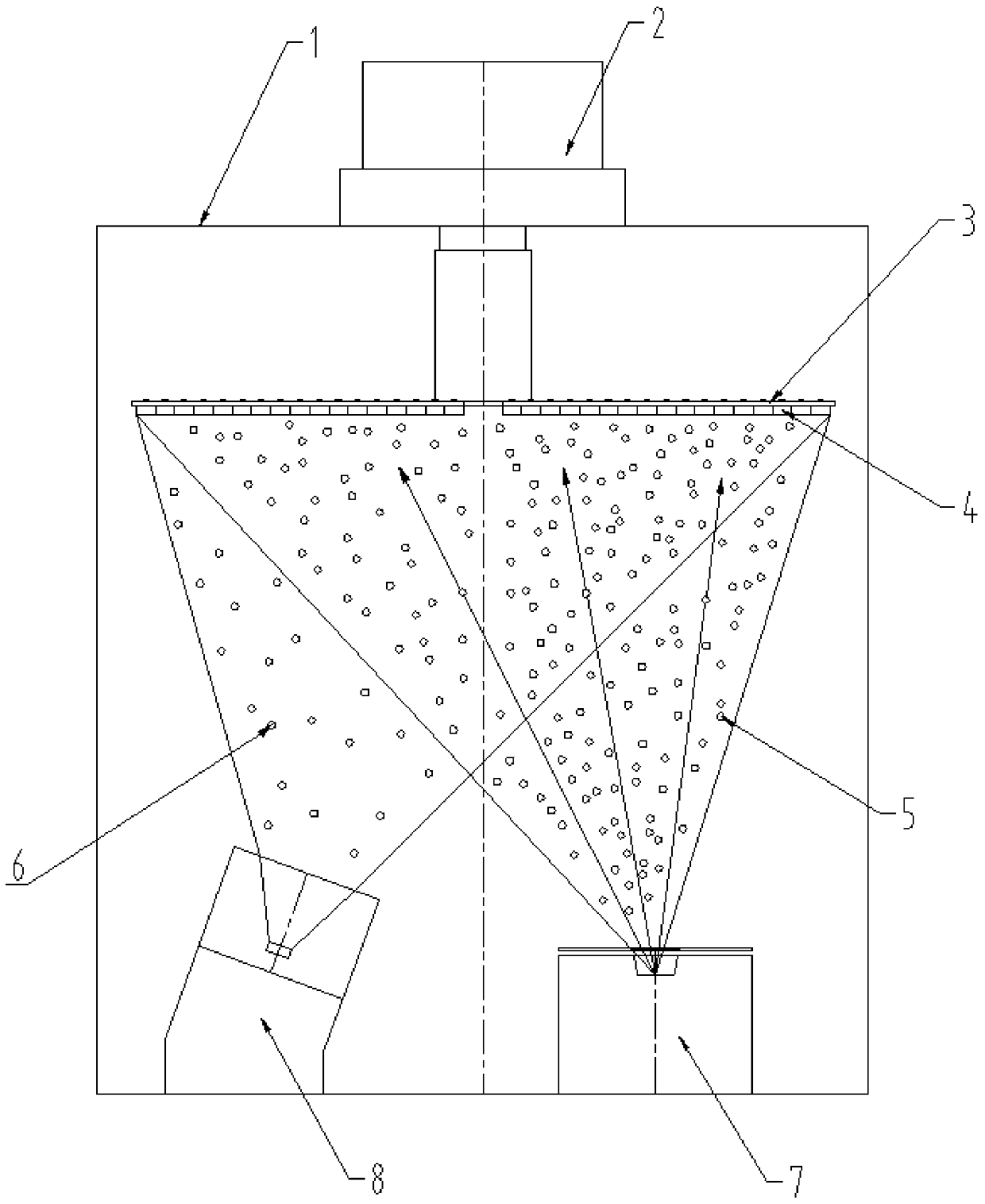

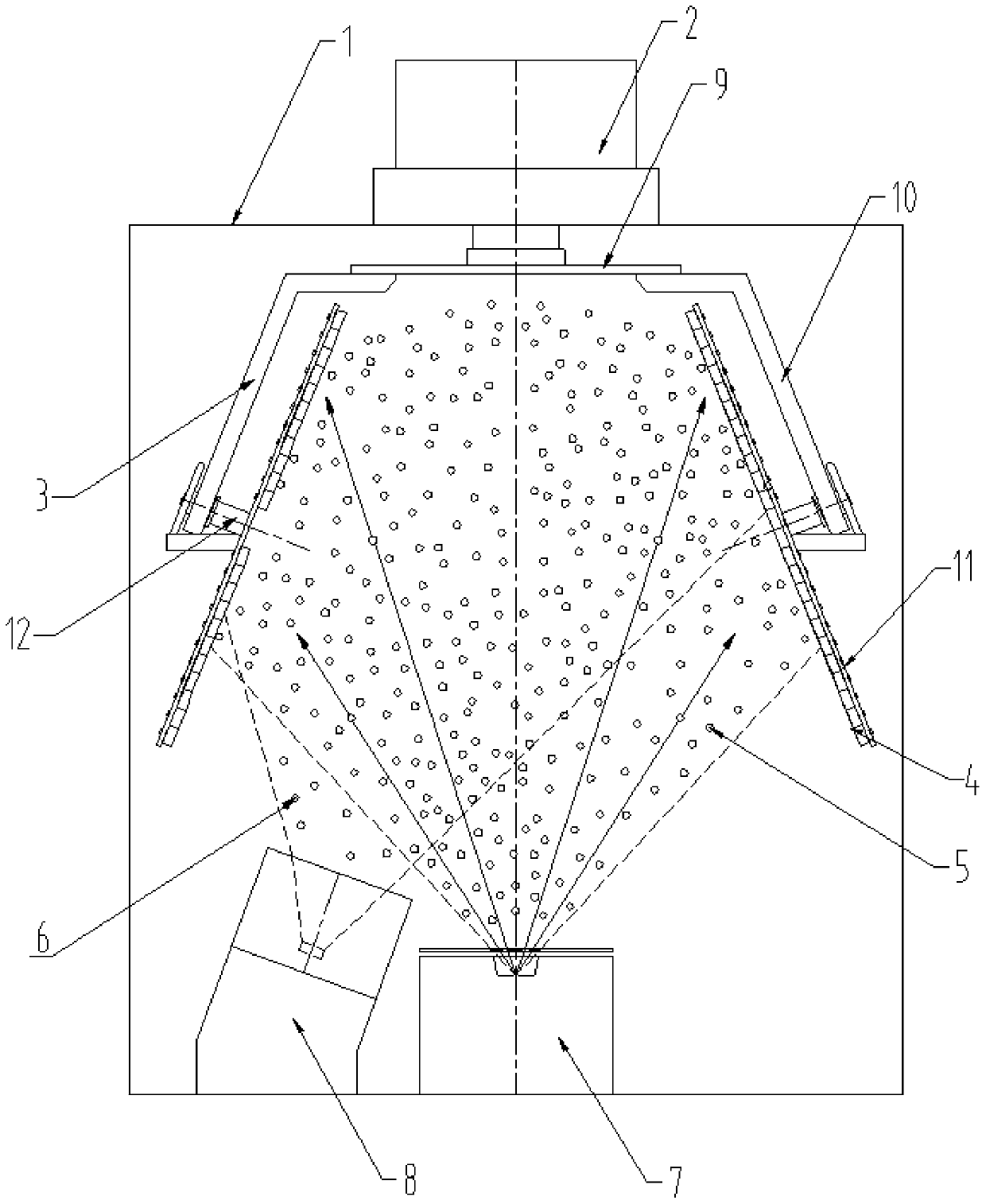

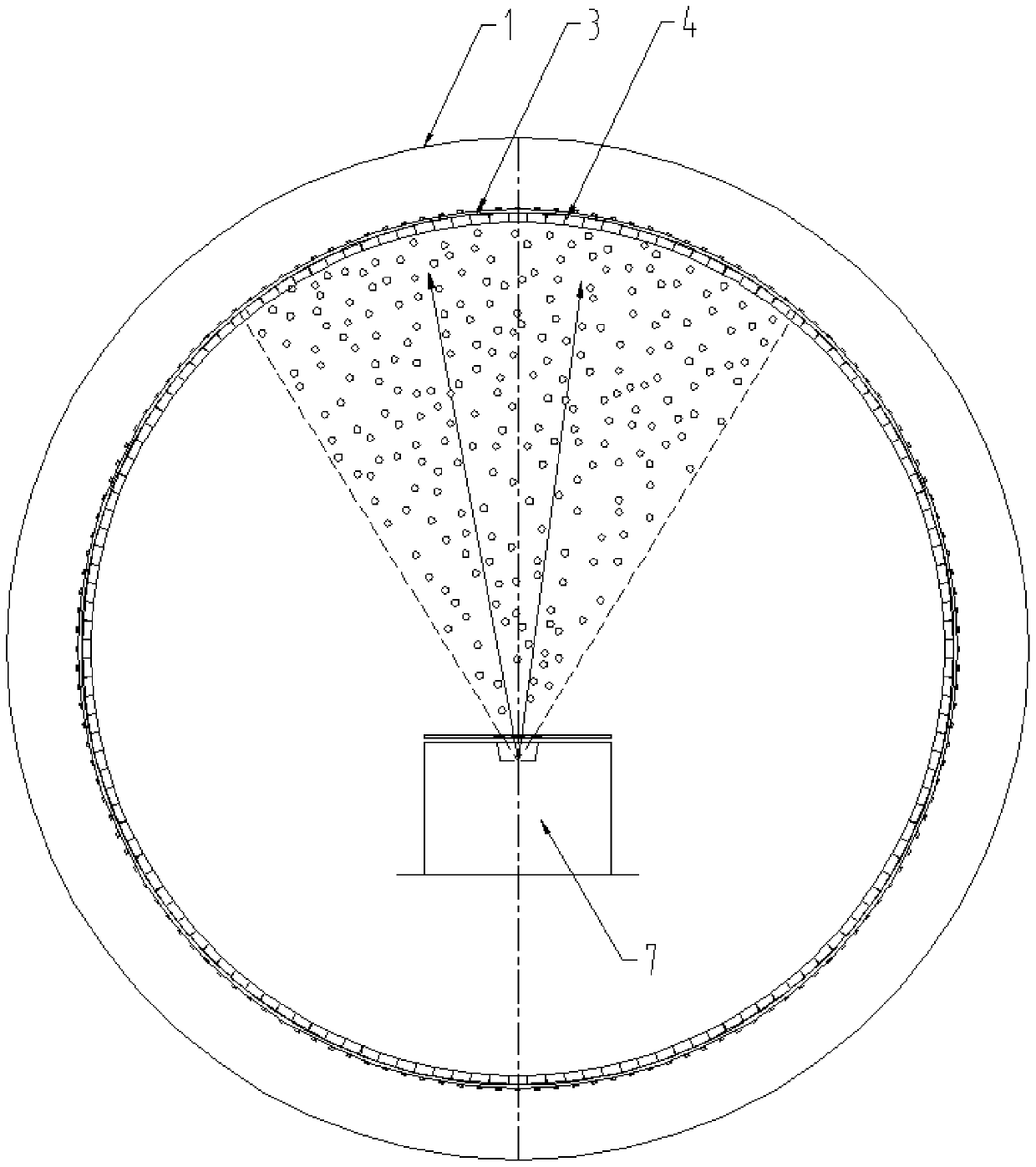

[0028] 1 is a vacuum chamber, 2 is a rotary drive system, 3 is a workpiece holder, 4 is a magnetic workpiece, 5 is gaseous molecules of terbium and dysprosium, 6 is argon ion, 7 is electron beam evaporation source, 8 is ion source, 9 is For the connecting plate, 10 is a connecting disk, 11 is a workpiece disk, and 12 is a rotating shaft.

[0029] As shown in combination 1-6, the equipment for evaporating terbium or dysprosium on the surface of magnetic materials includes a vacuum chamber, a workpiece holder in the vacuum chamber, a magnetic workpiece mounted on the workpiece holder, an electron beam evaporation source in the vacuum chamber and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com