Automatic Feedback Regulation System of Corn Peeling and Degerming Machine

An automatic feedback and adjustment system technology, which is applied in grain husking, grain degerming, grain processing, etc., can solve the problem of inability to realize automatic feedback control and fine operation, affect the color quality of finished products, taste, etc., and adjust the density of corn grains and other problems, to achieve the effect of improving the efficiency of peeling and germination, prolonging the life, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

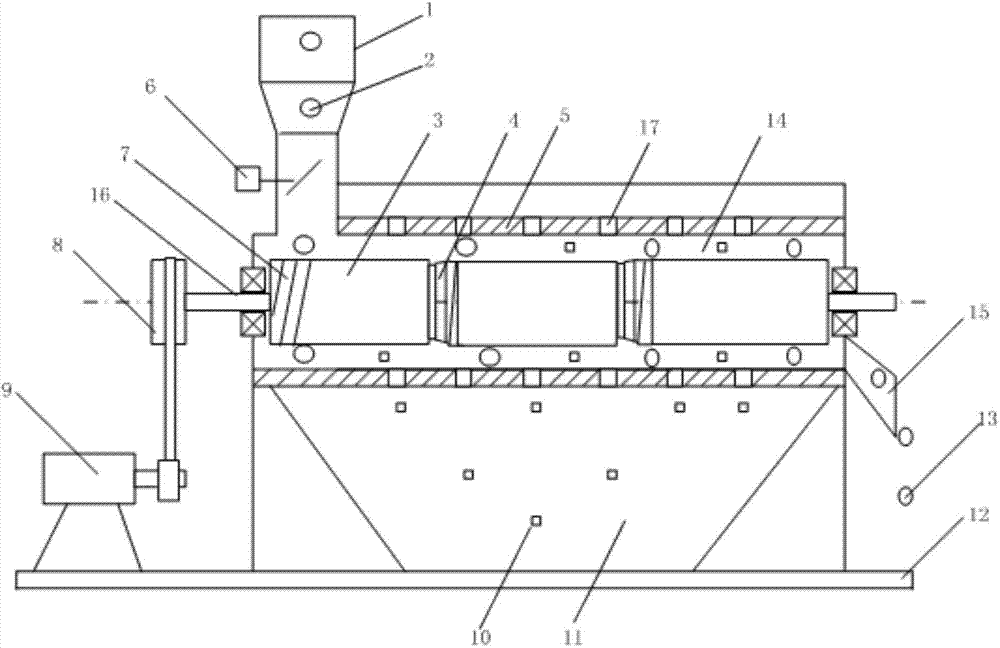

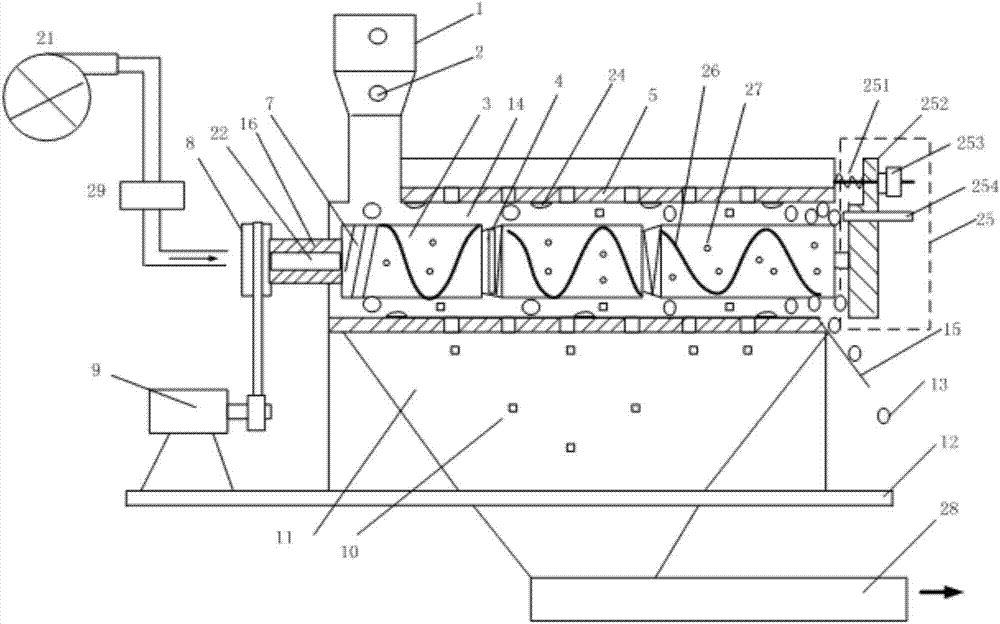

[0033] compared to figure 1 The traditional corn peeling and degerming machine, the improvement of the present invention is as follows:

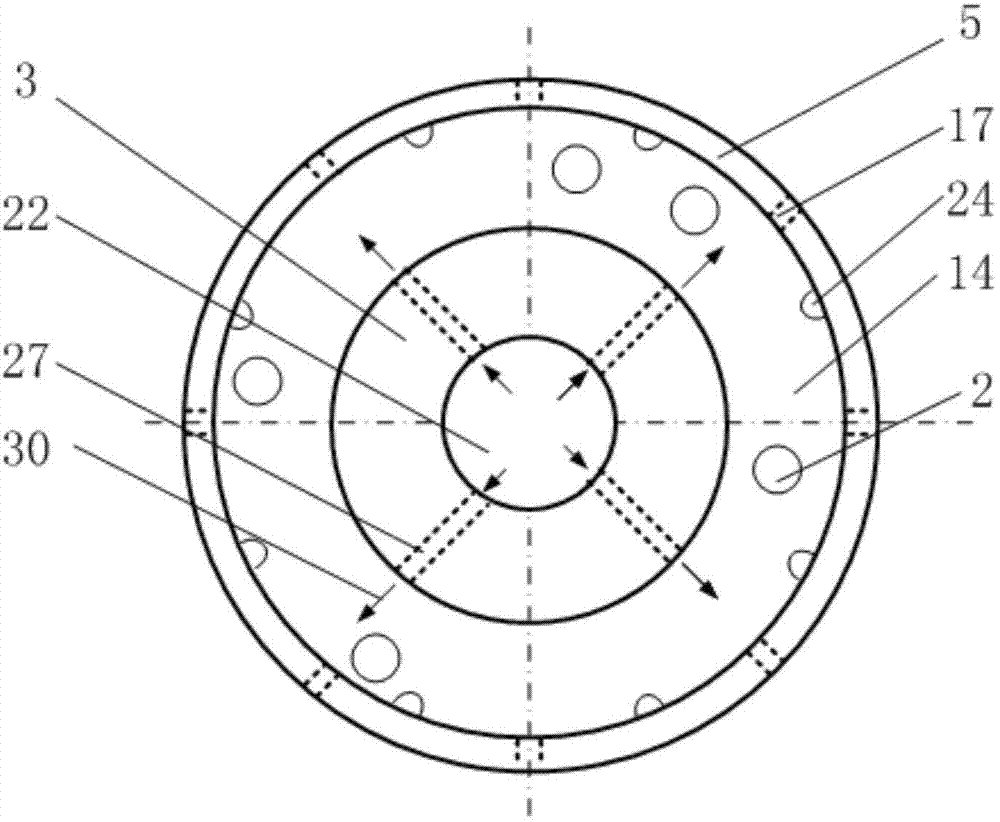

[0034] 1. Sand roller structure

[0035] like figure 2 and image 3 As shown, the traditional solid rotating shaft 16 is changed into a hollow structure 22, and one end of the hollow rotating shaft 16 is fixed with a belt pulley 8, and the emery roller 3 is sleeved on the other end of the hollow rotating shaft 16; The outlet is connected with the outlet of the blower fan 21 through a pipeline, and the surface of the emery roller 3 is evenly distributed with some air holes 27, so that the airflow of the blower fan 21 can be discharged into the processing chamber 14 through the air holes 27 during processing. In this way, when the sand roller 3 rotates and the sieve cylinder 5 is fixed and does not rotate, when the corn rubs and squeezes in the gap between the sand roller 3 and the sieve cylinder 5, the airflow 30 blown out by the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com