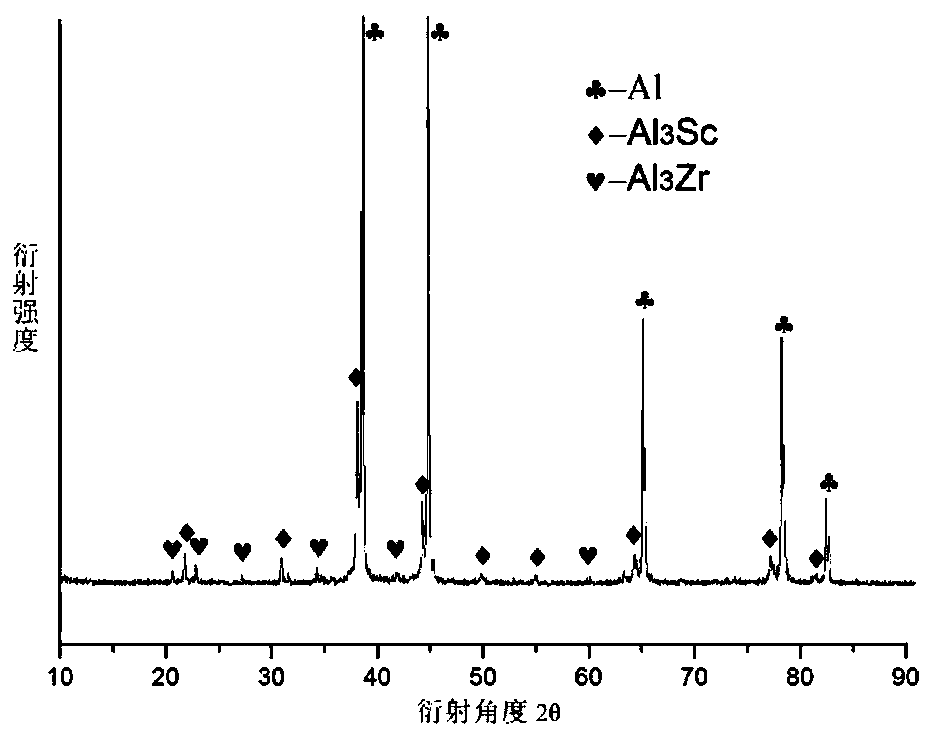

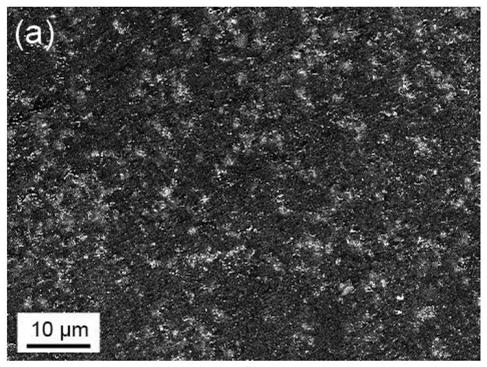

Preparation method of thin strip-type nano Al3(Sc, Zr)/Al compound inoculant

A composite inoculant, al-4sc-4zr technology, applied in the field of aluminum-based alloys, can solve the problems of less nucleation, high cost, and many technological processes, and achieve the effect of uniform size and refinement of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The first step, the preparation of raw materials:

[0055] Weighing the required amount of commercially purchased high-purity Sc and commercially purchased high-purity Zr, according to the mass percentage of each component element in the target alloy: Sc4%, Zr4%, the rest is Al, and prepare raw materials;

[0056] The second step is to prepare bulk Al-4Sc-4Zr master alloy by in situ autogenous method:

[0057] Put all the prepared raw materials weighed in the first step above into the crucible of the MZG series high vacuum induction melting furnace for melting, the vacuum degree is 5×10 -4 Pa, the melting temperature is 2000K, and the melting time is 10 minutes. The alloy is smelted, and the bulk Al-4Sc-4Zr master alloy is obtained by the in-situ autogenous method;

[0058] In the third step, the master alloy is forged to produce a melt quenching preform:

[0059]Put the massive Al-4Sc-4Zr master alloy obtained in the second step above into a crucible-type resistance ...

Embodiment 2

[0064] The first step, the preparation of raw materials:

[0065] With embodiment 1;

[0066] The second step is to prepare bulk Al-4Sc-4Zr master alloy by in situ autogenous method:

[0067] With embodiment 1;

[0068] In the third step, the master alloy is forged to produce a melt quenching preform:

[0069] With embodiment 1;

[0070] The fourth step, melt rapid quenching treatment to prepare thin strips of nano-Al 3 (Sc,Zr) / Al composite inoculant:

[0071] The above-mentioned step 3 master alloy is forged to obtain melt quick-quenching prefabricated parts and cut into small blocks with thickness, width and length of 7mm×7mm×10mm by wire cutting machine, cleaned with alcohol, air-dried, and put into quartz glass tube Among them, the quartz glass tube is covered with an induction heating coil, which is installed in the WK-IIB vacuum quenching furnace, and the vacuum in the WK-IIB vacuum quenching furnace is pumped to 5×10 by a molecular pump. -4 Pa, during which the ar...

Embodiment 3

[0073] The first step, the preparation of raw materials:

[0074] With embodiment 1;

[0075] The second step is to prepare bulk Al-4Sc-4Zr master alloy by in situ autogenous method:

[0076] With embodiment 1;

[0077] In the third step, the master alloy is forged to produce a melt quenching preform:

[0078] With embodiment 1;

[0079] The fourth step, melt rapid quenching treatment to prepare thin strips of nano-Al 3 (Sc,Zr) / Al composite inoculant:

[0080] The above-mentioned step 3 master alloy is forged to obtain melt quick-quenching prefabricated parts and cut into small blocks with thickness, width and length of 7mm×7mm×10mm by wire cutting machine, cleaned with alcohol, air-dried, and put into quartz glass tube Among them, the quartz glass tube is covered with an induction heating coil, which is installed in the WK-IIB vacuum quenching furnace, and the vacuum in the WK-IIB vacuum quenching furnace is pumped to 5×10 by a molecular pump. -4 Pa, during which the ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com