Novel high-temperature resistant environment-friendly steel structure fireproof coating and preparation method thereof

A fire retardant coating and high temperature resistant technology, applied in the direction of fire retardant coatings, polyurea/polyurethane coatings, coatings, etc. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of a high-temperature-resistant environmental protection steel structure fireproof coating:

[0029] (1) Preparation of silane-modified waterborne polyurethane resin

[0030] (1) Carry out batching as shown in the table below:

[0031] components Dosage(Kg) Polyol 12.3 polyisocyanate 19 chain extender 1.4 crosslinking agent 1.3 Triethylamine 4.2 coupling agent 0.8 Coalescent 1 total 40

[0032] (2) Preparation process

[0033] Add polyol, polyisocyanate, chain extender, and crosslinking agent into the reaction kettle according to the above ingredients, heat to 60°C and react, then add triethylamine, coupling agent, and add film-forming aids during the reaction, as needed An appropriate amount of dispersing aid can also be added to disperse at a high speed to obtain a silane-modified water-based polyurethane resin.

[0034] (2) Prepare high-temperature-resistant environmental protection steel s...

Embodiment 2

[0049] Preparation of a high-temperature-resistant environmental protection steel structure fireproof coating:

[0050] (1) Preparation of silane-modified waterborne polyurethane resin

[0051] (1) Carry out batching as shown in the table below:

[0052] components Dosage(Kg) Polyol 10.3 polyisocyanate 17 chain extender 1.5 crosslinking agent 1.2 Triethylamine 5.3 coupling agent 0.4 Coalescent 1.3 total 37

[0053] (2) Preparation process

[0054] According to the above ingredients, add polyol, polyisocyanate, chain extender, and crosslinking agent to the reaction kettle, heat to 60°C, add triethylamine, coupling agent, and add film-forming aids during the reaction. Add appropriate amount of dispersing aid, stir and disperse to prepare silane-modified water-based polyurethane resin.

[0055] (2) Prepare high-temperature-resistant environmental protection steel structure fireproof coating of the present invention...

Embodiment 3

[0066] Preparation of a high-temperature-resistant environmental protection steel structure fireproof coating:

[0067] (1) Preparation of silane-modified waterborne polyurethane resin

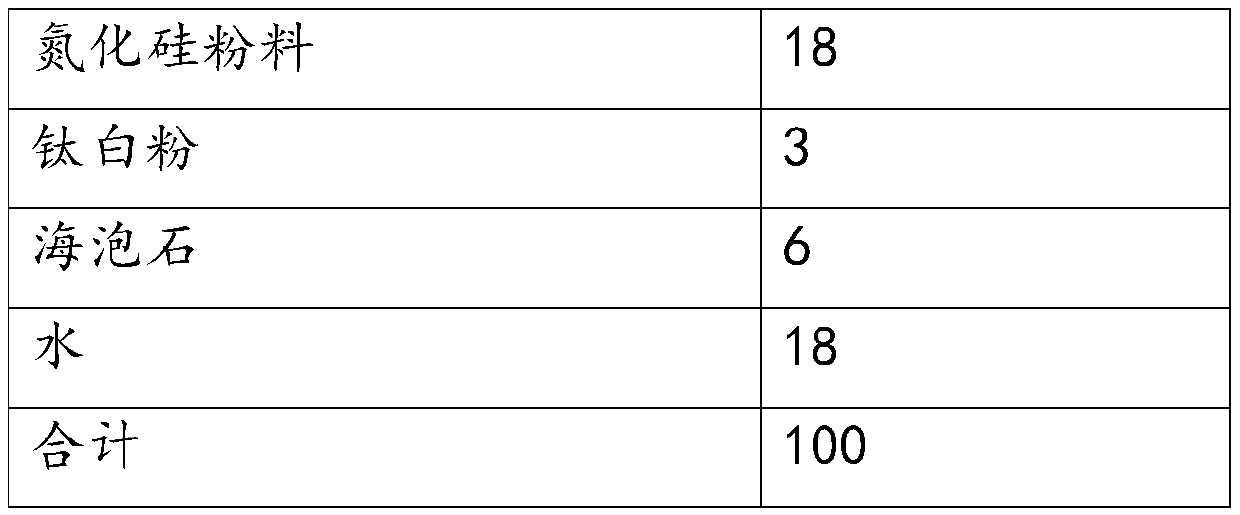

[0068] (1) Carry out batching as shown in the table below:

[0069]

[0070]

[0071] (2) Preparation process

[0072] Put polyol, polyisocyanate, chain extender, and crosslinking agent into the reaction kettle according to the above ingredients, heat it to about 65°C, add triethylamine, coupling agent, and add film-forming aid during the reaction process. Appropriate amount of dispersant, high-speed dispersion, to prepare silane-modified water-based polyurethane resin.

[0073] (2) Prepare high-temperature-resistant environmental protection steel structure fireproof coating of the present invention

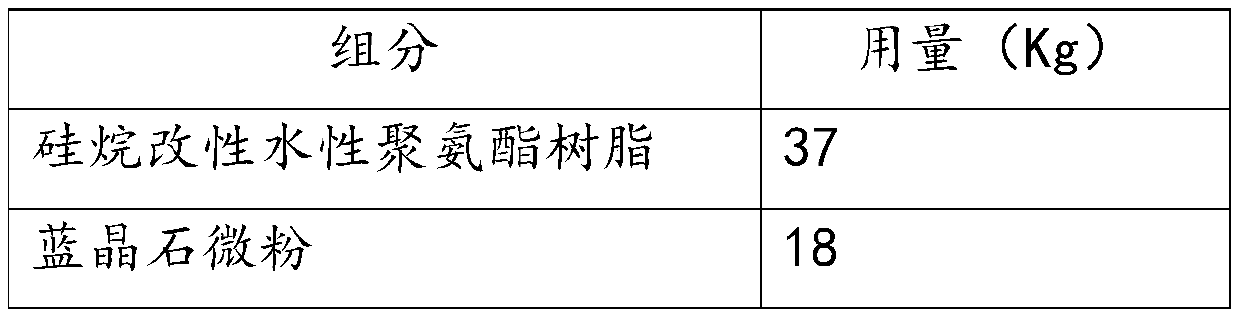

[0074] (1) The main components and proportions of high temperature resistant and environmentally friendly steel structure fire retardant coatings are detailed in the table below:

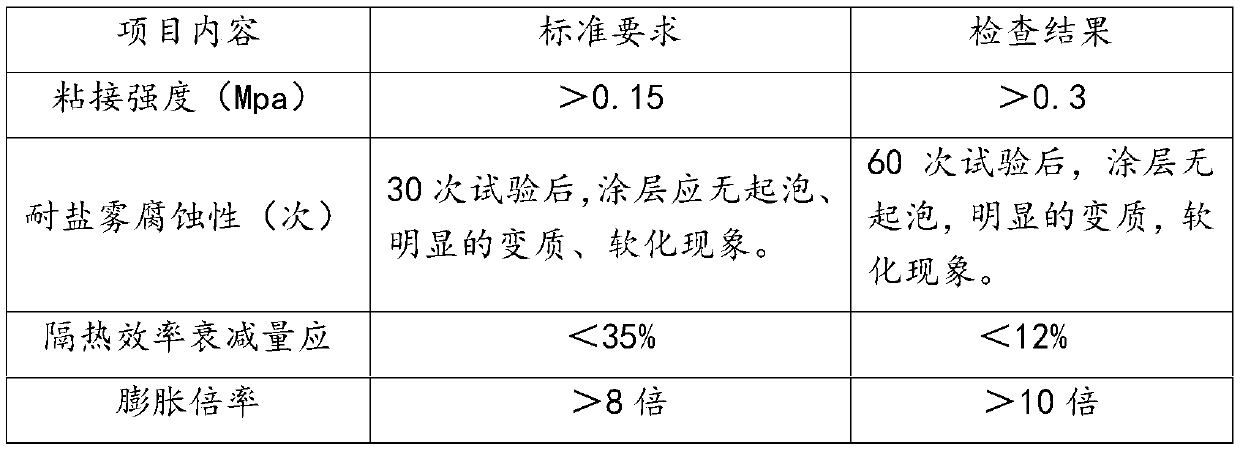

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com