Preparation method of cellulose nanocrystals

A nanocrystal and cellulose technology, applied in the field of preparation of cellulose nanocrystals, can solve the problems of low yield, high energy consumption, and long preparation cycle, and achieve the effects of less environmental pollution, uniform particle size distribution, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

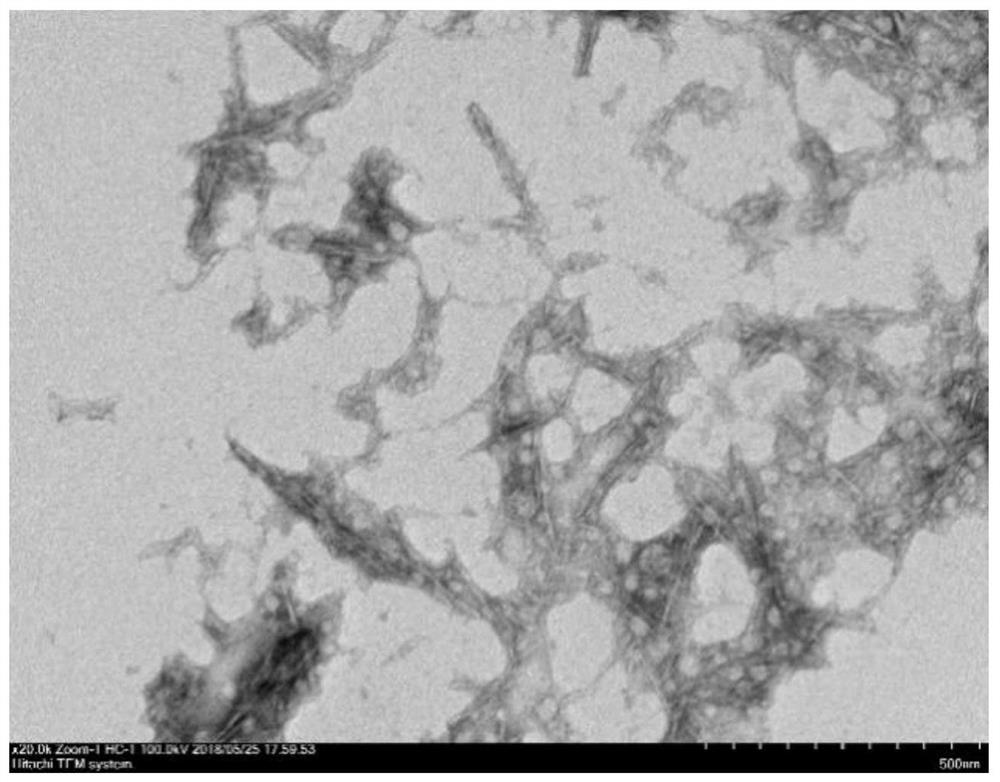

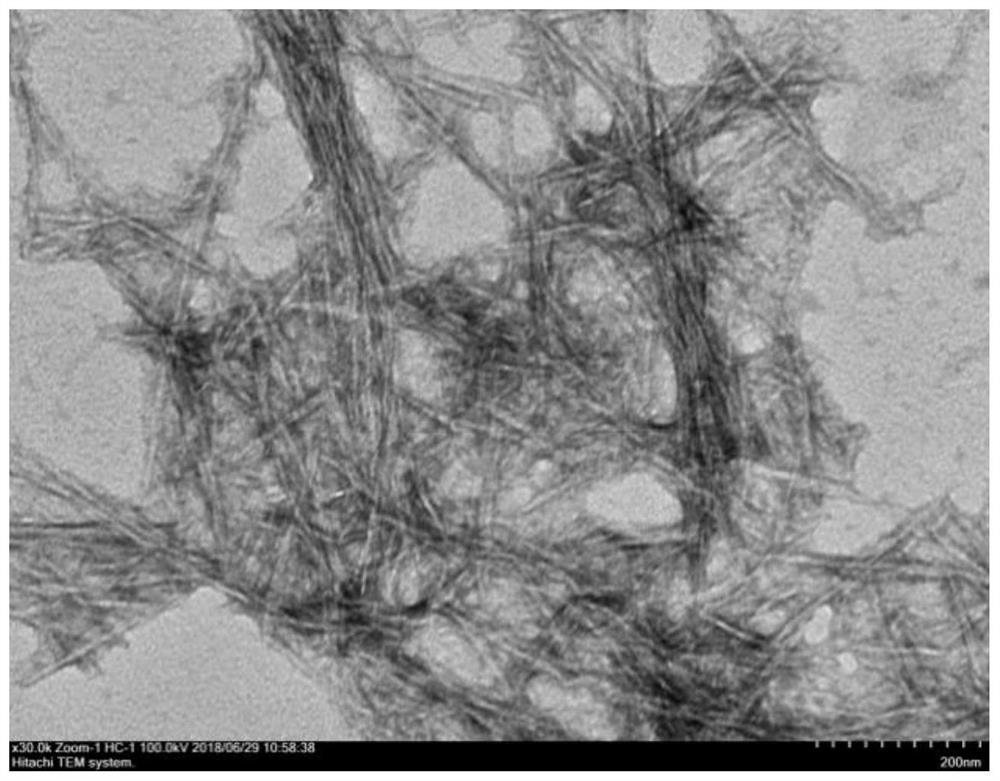

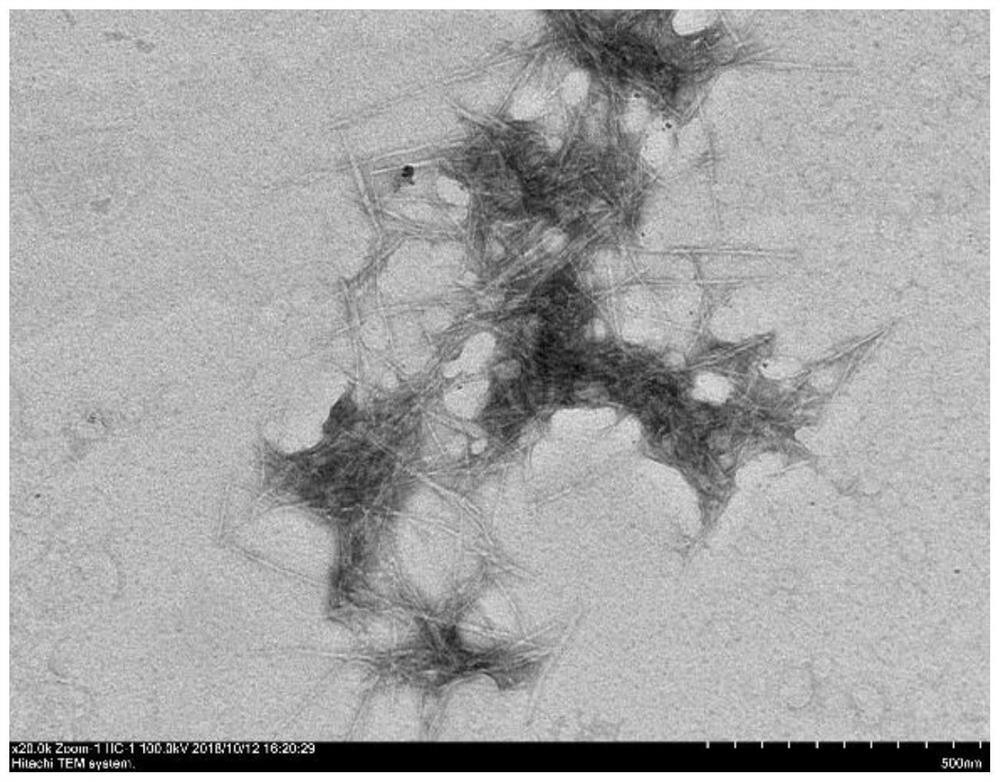

[0040] Weigh 0.05g of microcrystalline cellulose powder as cellulose raw material and slowly add it into a 10mL glass bottle, add 1g of 40% TBPH (tetrabutylphosphine hydroxide, the same below) with a mass fraction of 1g and add a magnetic rotor, put the glass bottle into 50 ℃ in a constant temperature oil bath for 1 h, and the samples were mixed evenly by magnetic stirring during the processing. After the treatment, add 10 mL of deionized water to regenerate the cellulose, pour the regenerated cellulose into a beaker, and filter and clean it with a suction filter. After repeated washing 3 times, 50 mL of deionized water was added to the washed regenerated cellulose again. The cleaned regenerated cellulose was ultrasonically dispersed with an ultrasonic cell pulverizer, the ultrasonic power was 1200W, and the ultrasonic time was 4min. A mixed solution of cellulose nanocrystals was prepared after ultrasonication. The prepared cellulose nanocrystal mixed solution was centrifuge...

Embodiment 2

[0042] Weigh 0.05g of bagasse pulp as cellulose raw material and slowly add it into a 10mL glass bottle, add 1g of TBPH with a mass fraction of 40% and add a magnetic rotor, put the glass bottle in a constant temperature oil bath at 50°C for 1 hour, and process The samples were mixed homogeneously by magnetic stirring. After the treatment, add 10 mL of deionized water to regenerate the cellulose, pour the regenerated cellulose into a beaker, and filter and clean it with a suction filter. After repeated washing 3 times, 50 mL of deionized water was added to the washed regenerated cellulose again. The cleaned regenerated cellulose was ultrasonically dispersed with an ultrasonic cell pulverizer, the ultrasonic power was 1200W, and the ultrasonic time was 4min. A mixed solution of cellulose nanocrystals was prepared after ultrasonication. The prepared cellulose nanocrystal mixed solution was centrifuged at a speed of 8000 r / min for 5 minutes in a high-speed centrifuge. Pour out...

Embodiment 3

[0044]Weigh 0.05g of the cellulose-rich material prepared at a temperature of 240°C in the oil pan in the component separation (the preparation method of the cellulose-rich material refers to Example 16) as the cellulose raw material and slowly add it to a 10mL glass bottle, adding 1g mass fraction It is 40% TBPH and a magnetic rotor is added, and the glass bottle is placed in a constant temperature oil bath at 50°C for 1 hour. During the treatment, the sample is mixed evenly by magnetic stirring. After the treatment, add 10 mL of deionized water to regenerate the cellulose, pour the regenerated cellulose into a beaker, and filter and clean it with a suction filter. After repeated washing 3 times, 50 mL of deionized water was added to the washed regenerated cellulose again. The cleaned regenerated cellulose was ultrasonically dispersed with an ultrasonic cell pulverizer, the ultrasonic power was 1200W, and the ultrasonic time was 4min. A mixed solution of cellulose nanocrysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com