A kind of mortar concrete internal curing material and preparation method thereof

A mortar concrete and material technology, applied in the field of mortar concrete production soil, can solve volume shrinkage and other problems, achieve the effects of reducing water consumption, reducing porosity, and increasing concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of mortar concrete internal maintenance material, described mortar concrete internal maintenance material comprises 78% of circulating fluidized bed sulfur-fixing ash, 4% of hydroxypropyl methylcellulose ether, 1% of hydroxypropyl Base guar gum, 15% masking agent, 2% regulator.

[0035] The masking agent includes 83% polyvinyl alcohol, 15% chitosan, 1.5% sucrose and 0.5% stearic acid in mass percent.

[0036] The regulator includes 91% alginic acid, 2.5% gelatin, 5% beta-cyclodextrin and 1.5% sodium ethylenediaminetetraacetate in terms of mass percentage.

[0037] The degree of deacetylation of the chitosan is 92%.

[0038] The preparation method of the internal maintenance material of the mortar concrete comprises the following steps:

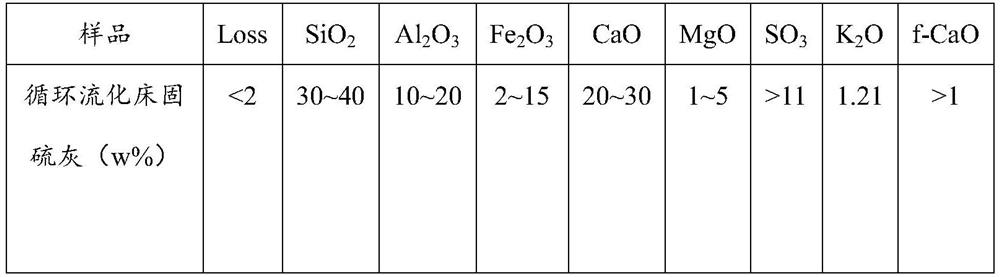

[0039] 1. Sorting: Take 1000g of circulating fluidized bed sulfur-fixing ash, the circulating fluidized bed sulfur-fixing ash meets the requirements of Table 1, pass the circulating fluidized bed sulfur-fixing ash through a 1.18m...

Embodiment 2

[0049] A kind of mortar concrete internal curing material, said mortar concrete internal curing material comprises 77% of circulating fluidized bed sulfur-fixing ash, 3% of hydroxypropyl methylcellulose ether, 0.5% of hydroxypropyl Base guar gum, 18% masking agent, 1.5% regulator.

[0050] The masking agent includes 81% polyvinyl alcohol, 16% chitosan, 2% sucrose and 1% stearic acid in terms of mass percentage.

[0051] The adjusting agent includes 90% alginic acid, 3% gelatin, 5% beta-cyclodextrin and 2% sodium ethylenediaminetetraacetate in terms of mass percentage.

[0052] The degree of deacetylation of the chitosan is 95%.

[0053] A method for preparing a mortar concrete internal maintenance material, comprising the following steps:

[0054] 1. Sorting: Take 1500g of circulating fluidized bed sulfur-fixing ash, the circulating fluidized bed sulfur-fixing ash meets the requirements of Table 1, pass the circulating fluidized bed sulfur-fixing ash through a 1.18mm square ...

Embodiment 3

[0062] Based on the application of a mortar concrete internal curing material: soak the mortar concrete internal curing material in 2 times the volume of water for 48 hours, and mix the mortar concrete internal curing material at a rate of 60kg / m 3 The addition of a certain amount will not produce the customary floating phenomenon like the light aggregates of the prior art, and will basically have no effect on the working performance of the concrete. At the same time, it can improve the cohesion and fluidity of the mortar, reduce the bleeding phenomenon, and increase the concrete slump by 20-30mm. The relative humidity RH inside the concrete was detected, and it was found that the relative humidity was greater than 95% on the 3d day, greater than 92% on the 7th day, and greater than 80% on the 28th day, which is a significant improvement over the prior art.

[0063] In terms of volume stability of concrete, after adding the mortar concrete internal curing material provided by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com