Hydraulic coupler based on crystallization and phosphorus removal with short-cut nitrification and synchronous denitrification

A hydraulic coupler, nitrification and crystallization technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the content of chemical substances in water with no obvious effect, increase the difficulty of industrial wastewater treatment, Water quality secondary pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

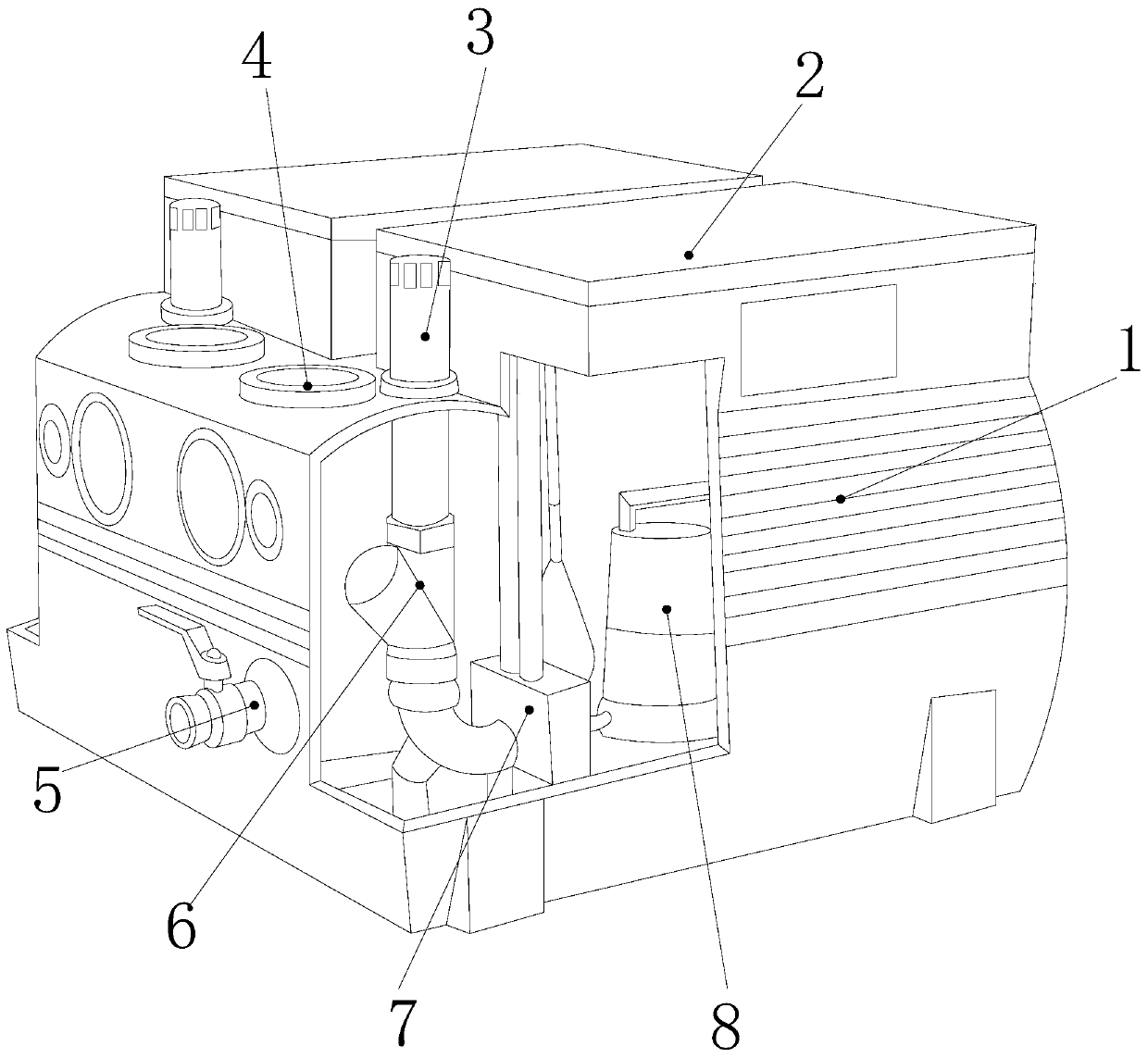

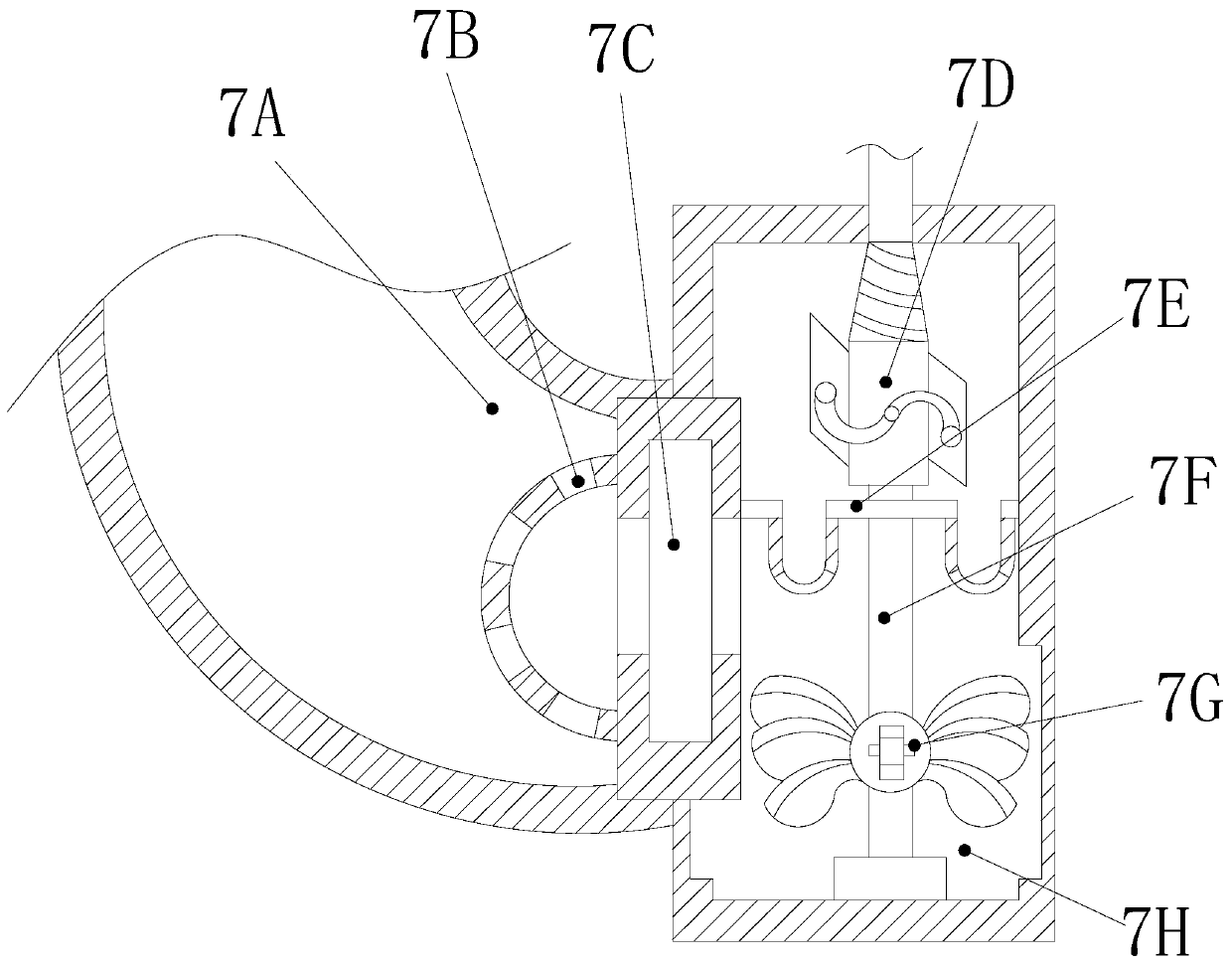

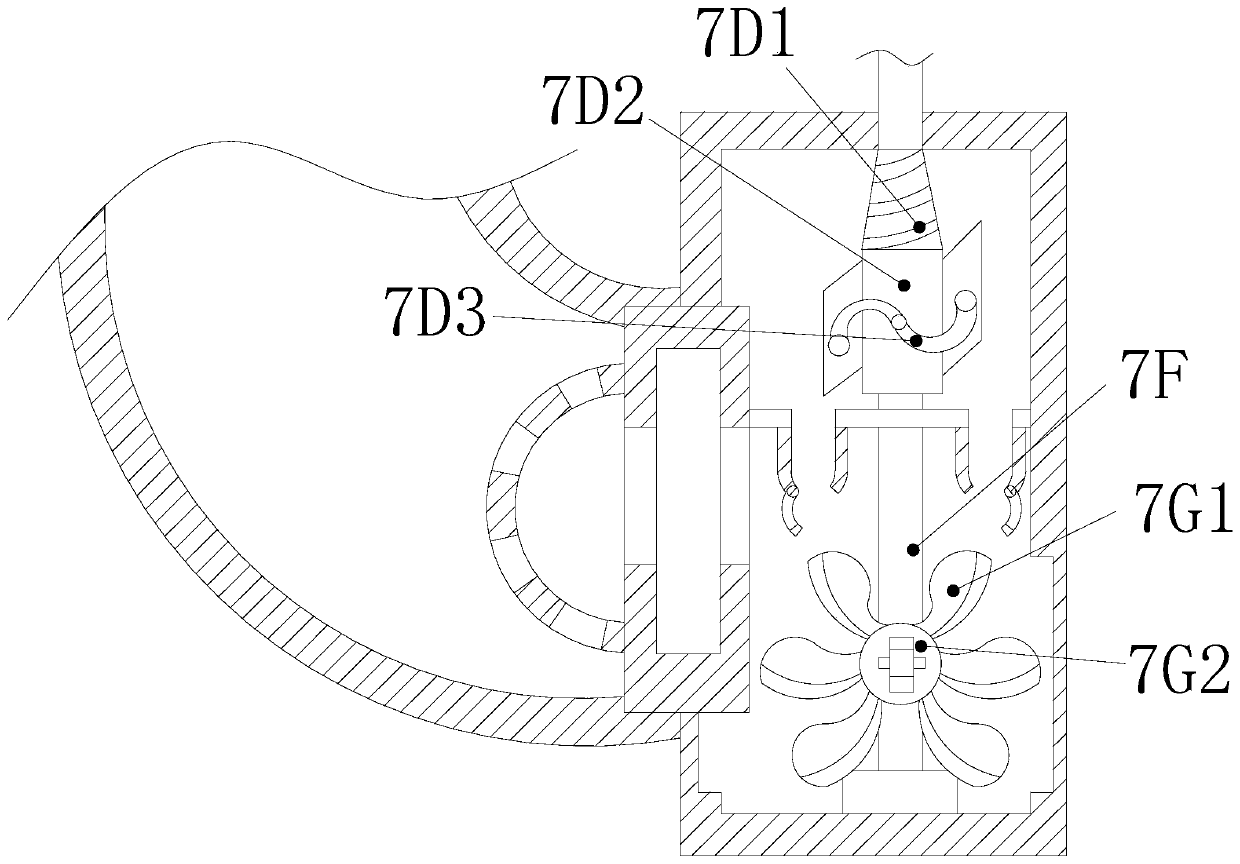

[0031] see Figure 1-Figure 7 , the present invention provides a hydraulic coupler based on short-range nitrification synchronous denitrification crystallization and dephosphorization, the structure of which includes: water pump casing 1, sealing cover plate 2, exhaust cylinder 3, pipe interface frame 4, shut-off valve 5 , a three-way valve pipeline 6, a double paddle coupling mechanism 7, and an air pump 8. The sealing cover plate 2 is provided with two and is closely attached to the top surface of the water pump case shell 1. The exhaust cylinder 3 and There are two pipeline interface frames 4 and they are embedded in the upper left corner of the water pump case shell 1. The exhaust cylinder 3 communicates with the double-pulp coupling mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com