Self-supporting variable-frequency pulling winch

A traction winch, self-supporting technology, applied in the direction of load suspension components, fluid pressure actuating system components, fluid pressure actuating devices, etc., can solve potential safety hazards, affect the retraction efficiency and safety assurance of fully mechanized mining face, and is time-consuming Labor and other problems, to achieve the effect of low labor intensity, good market promotion prospects, and improved overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

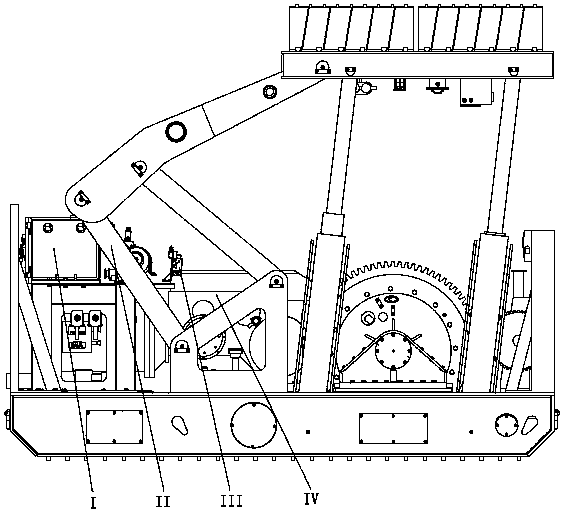

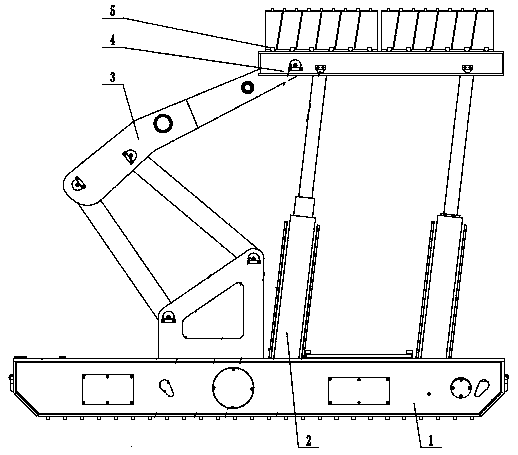

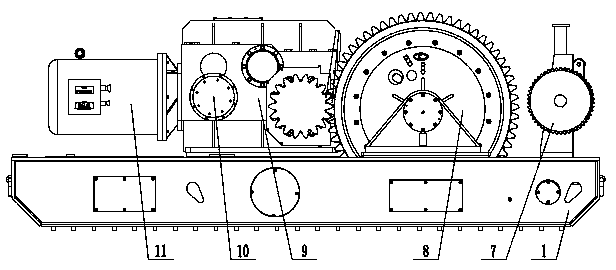

[0025] The specific implementation manner of the patent of the present invention will be further described in conjunction with the accompanying drawings.

[0026] As shown in the figure, the self-supporting frequency conversion traction winch mainly includes an integral chassis 1, four column cylinders 2, a four-bar linkage mechanism 3, an integral ceiling 4, a raised seat 5, an electrical control box 6, a winch mill 7, and a cycloid 8. Gear box 9, multi-disc wet brake 10, frequency conversion motor 11 and related connecting pins and bolts, etc. The winch realizes the integrated design of self-supporting fixation and traction functions. The winding and unwinding cables of the winch mill can be adjusted by frequency conversion, and various actions and functions can be operated remotely. The electrical system has automatic parameter detection and protection functions.

[0027] Specifically, the self-supporting variable frequency traction winch is mainly composed of several parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com