A kind of preparation method of bionic shell material

A shell and bionic technology, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of cumbersome steps, poor uniformity, performance difference, etc., and achieve the effect of simple process and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

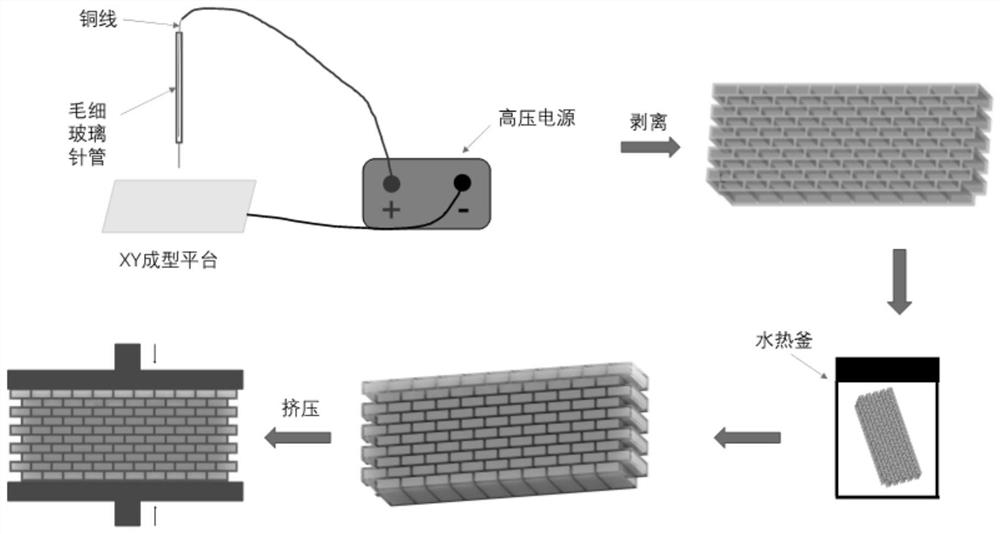

[0030] A preparation method of a bionic shell material in this embodiment comprises the following steps:

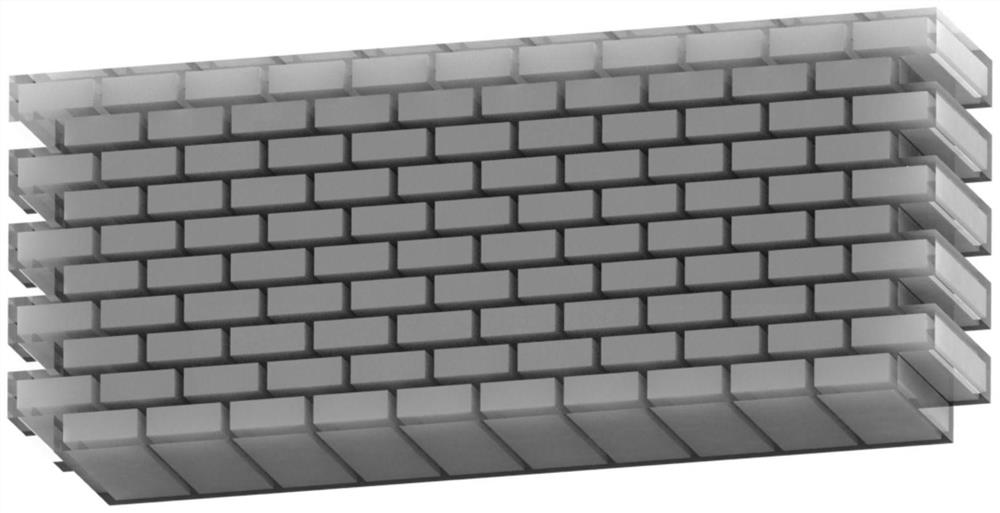

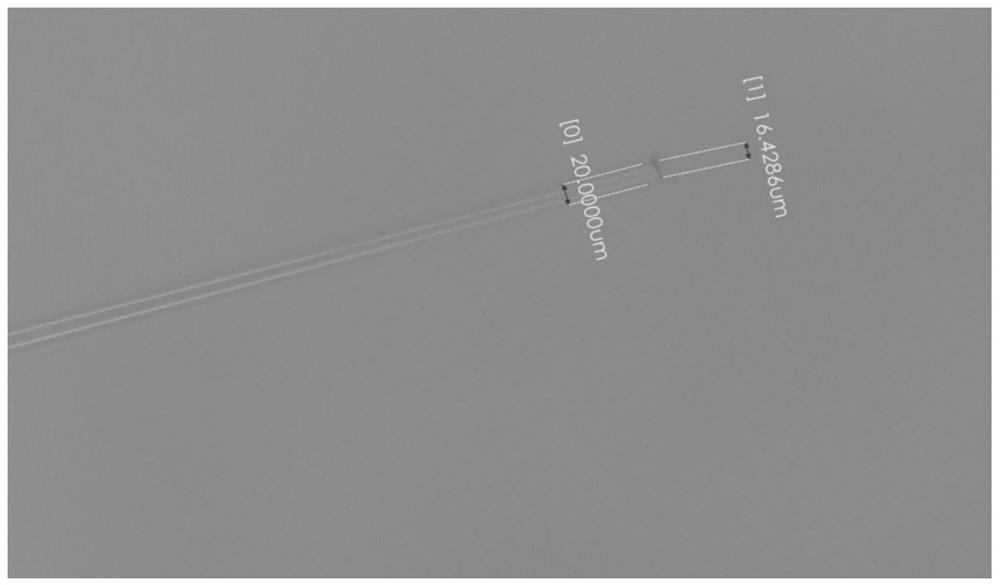

[0031] (1) Solidworks is used to construct the "brick-wall" structure. The small rectangular holes that constitute the organic framework are 100 μm long, 50 μm high, and 10 μm thick, such as figure 1 shown;

[0032] (2) Configure photosensitive resin: oligomer selects urethane acrylate, the mass fraction is 49%, the diluent selects isobornyl acrylate, the mass fraction is 50%, and the photoinitiator selects 2,4,6-trimethylbenzyl Acyl-diphenylphosphine oxide, the mass fraction is 1%, magnetically stirred at room temperature for 12 hours to obtain the desired photosensitive resin;

[0033] (3) Inject the prepared photosensitive resin into the ultra-fine capillary glass tube with a syringe and insert the copper wire. The copper wire is connected to the positive pole of the power supply, and the bottom plate is connected to the negative pole of the power supply. The resin is...

Embodiment 2

[0037] A preparation method of a bionic shell material in this embodiment comprises the following steps:

[0038] (1) Solidworks is used to construct the "brick-wall" structure. The small rectangular holes that constitute the organic framework are 100 μm long, 50 μm high, and 10 μm thick;

[0039] (2) configure photosensitive resin: the oligomer selects urethane acrylate, the mass fraction is 48%, the diluent selects isobornyl acrylate, tripropylene glycol diacrylate, and the mass fraction is 25%, and the photoinitiator selects 2, 4,6-trimethylbenzoyl-diphenylphosphine oxide, the mass fraction is 2%, magnetically stirred at room temperature for 12 hours to obtain the desired photosensitive resin;

[0040] (3) Inject the prepared photosensitive resin into the ultra-fine capillary glass tube with a syringe and insert the copper wire. The copper wire is connected to the positive pole of the power supply, and the bottom plate is connected to the negative pole of the power supply. ...

Embodiment 3

[0044] A preparation method of a bionic shell material in this embodiment comprises the following steps:

[0045] (1) Solidworks is used to construct the "brick-wall" structure. The small rectangular holes that constitute the organic framework are 100 μm long, 50 μm high, and 10 μm thick;

[0046](2) configure photosensitive resin: the oligomer selects epoxy acrylate and aliphatic urethane acrylate, and the mass fraction is 22.5%, and the diluent selects ethoxylated trimethylolpropane triacrylate, and the mass fraction is 52%. The initiator is phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, the mass fraction is 3%, and magnetically stirred at room temperature for 12 hours to obtain the desired photosensitive resin;

[0047] (3) Inject the prepared photosensitive resin into the ultra-fine capillary glass tube with a syringe and insert the copper wire. The copper wire is connected to the positive pole of the power supply, and the bottom plate is connected to the negative pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com