Supported porous metal-organic Pd catalyst, and preparation method and application thereof

A porous metal and catalyst technology, applied in the chemical industry, can solve the problems of high environmental pollution, high energy consumption in production, difficult to separate, etc., and achieve the effects of high mechanical strength, avoiding dehydrogenation reaction, and excellent activity of cyclization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

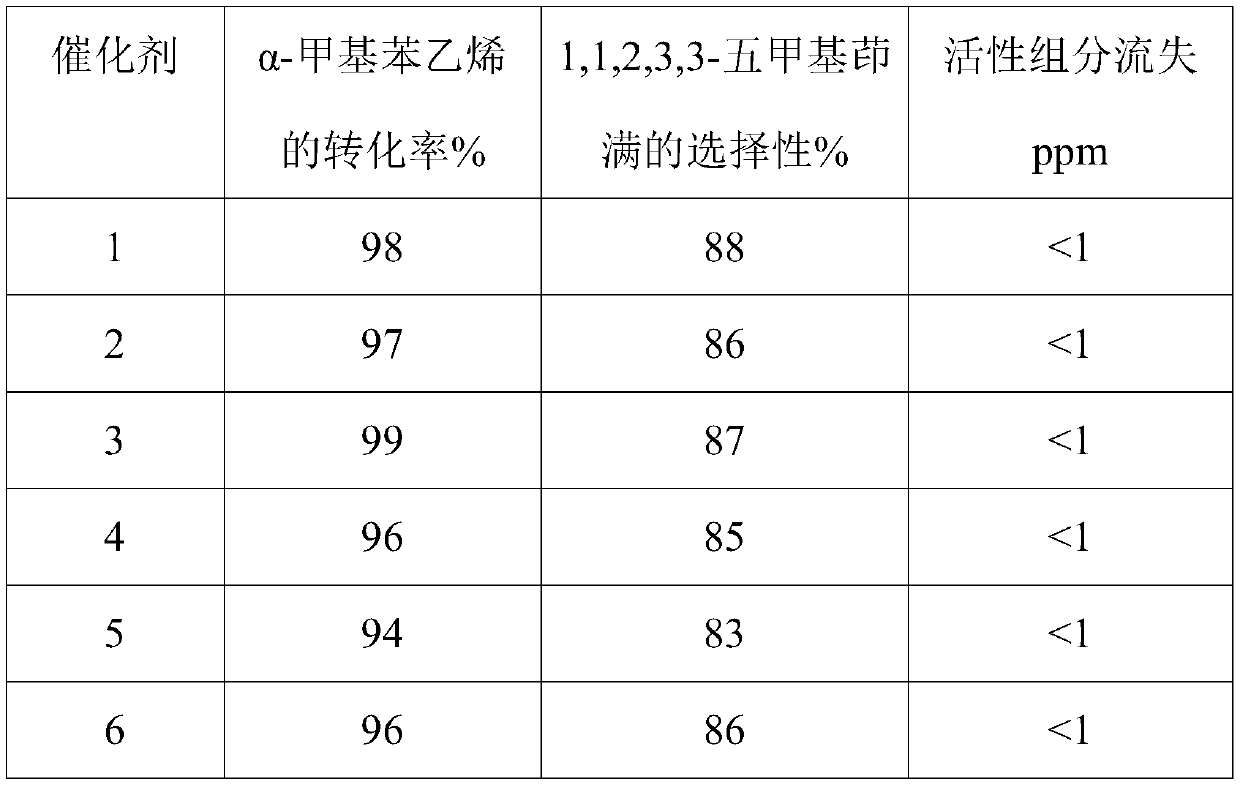

Examples

Embodiment 1

[0035] Mix 56.1g of palladium acetate and 266g of 2,2-bipyridine in 500g of distilled water, raise the temperature to 60°C and stir for 4 hours; dissolve 333.7g of copper nitrate in 500g of water to prepare a copper nitrate aqueous solution. Add the copper nitrate aqueous solution to the mixed aqueous solution of palladium acetate and 2,2-bipyridine, and add 126g of 4A molecular sieves under stirring to obtain the slurry A;

[0036] Dissolve sodium carbonate in water to form a 20wt% sodium carbonate solution, which is the alkaline precipitant B, heat the slurry A and the alkaline precipitant B to 60°C, and slowly add the alkaline precipitant B to the slurry A The pH of the system is 7.5, and the reaction temperature of the precipitation process is controlled at 60°C; then the slurry is obtained after aging at 70°C for 3 hours;

[0037] The slurry was filtered, washed with deionized water, and the filter cake was dried at 110° C. for 12 hours, calcined at 350° C. for 3 hours, cru...

Embodiment 2

[0039] Mix 67.4g of palladium acetate and 200g of 2,2-bipyridine in 500g of distilled water, raise the temperature to 60°C and stir for 4 hours; dissolve 406g of zinc acetate in 1000g of water to prepare a zinc acetate aqueous solution. Add the zinc acetate aqueous solution to the mixed solution of palladium acetate and 2,2-bipyridyl, add 155.6g of silicon dioxide under stirring and mix to obtain slurry A;

[0040] Dissolving ammonium bicarbonate in water to form a 20wt% ammonium bicarbonate solution is the alkaline precipitant B, respectively heating the slurry A and the alkaline precipitant B to 70°C, and slowly adding the alkaline precipitant B to In the slurry A until the pH of the system is 8.0, the reaction temperature of the precipitation process is controlled to 70°C; then the slurry is obtained after aging at 70°C for 3 hours;

[0041] The slurry was filtered, washed with deionized water, and the filter cake was dried at 100° C. for 10 h, calcined at 300° C. for 4 h, ...

Embodiment 3

[0043] Mix 88.6g of palladium chloride, 212.8g of 5,10,15,20-tetra(4-amino-phenyl)porphyrin in 500g of distilled water, raise the temperature to 80°C and stir for 4 hours; dissolve 167.7g of silver nitrate in 200g of water to prepare into an aqueous solution of silver nitrate. Silver nitrate aqueous solution was added to palladium chloride, 5,10,15,20-tetrakis(4-amino-phenyl)porphyrin mixed solution, and 159.5 g of neutral alumina was added under stirring to obtain slurry A;

[0044] Dissolving sodium bicarbonate in water to form a 20wt% sodium bicarbonate solution is the alkaline precipitant B, respectively heating the slurry A and the alkaline precipitant B to 60°C, and slowly adding the alkaline precipitant B to In the slurry A, the pH of the system is 8.5, and the reaction temperature of the precipitation process is controlled at 60°C; then aged at 80°C for 2 hours to obtain the slurry;

[0045] The slurry was filtered, washed with deionized water, and the filter cake was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com