Method for preparing cholestenone by using eutectic mixture as solubilization promoting agent through resting cell transformation

A technology of resting cell transformation and eutectic matter, applied in fermentation and other directions, can solve the problems of difficult contact between steroids and biological enzymes, affecting the speed and yield of steroid transformation reactions, low solubility, etc. It is of great significance to achieve industrialization , Mild operating conditions, the effect of improving the dispersion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

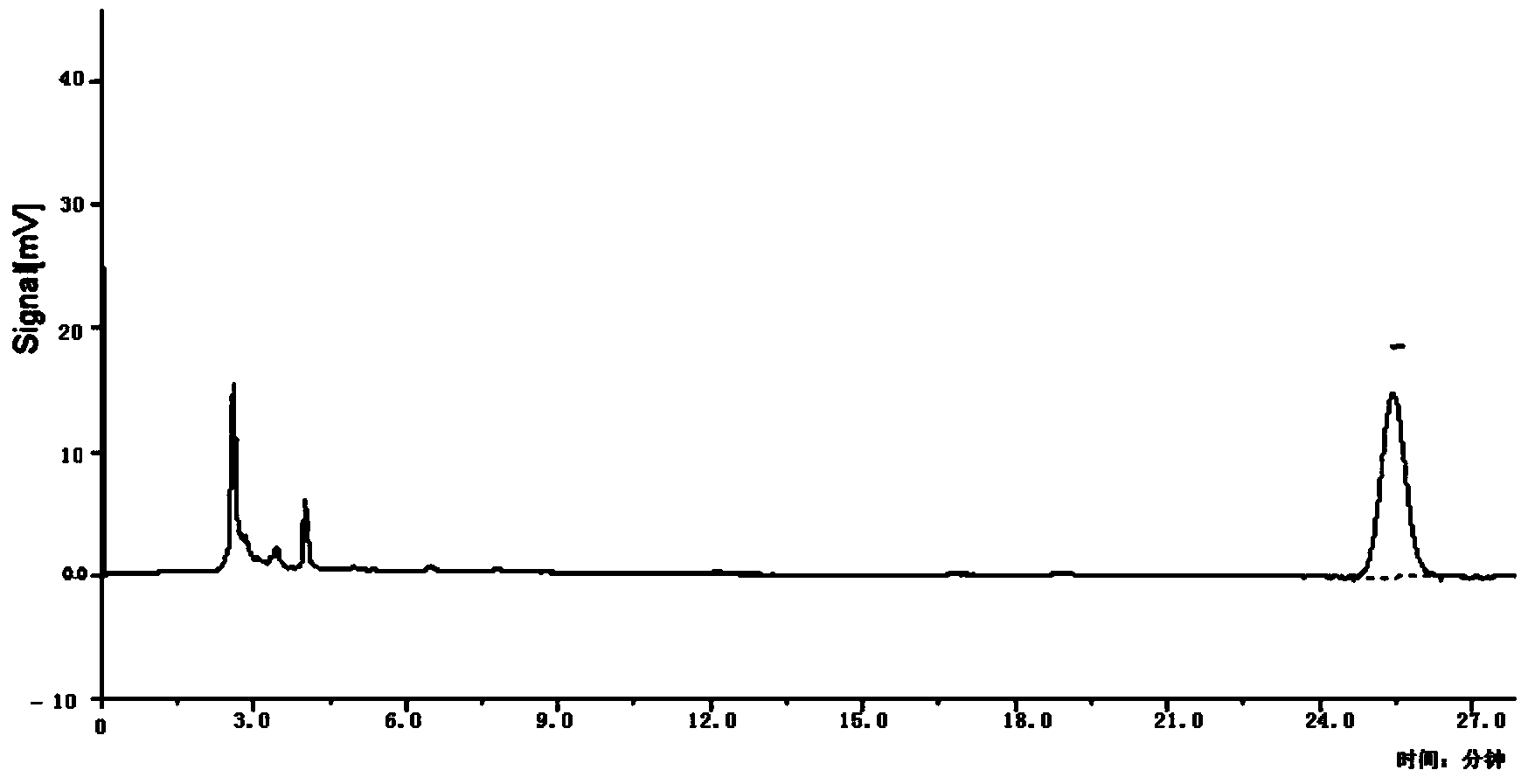

[0042]A method for preparing cholestenone using eutectic as a solubilizing agent by transforming resting cells. In this embodiment, the catalytic conversion effect of different types of DES is detected by changing the mixing ratio of DES, as follows:

[0043] ⑴ Scrape Arthrobacter simplex into sterile water, shake and mix well, and add it into a 50ml / 250ml shake flask for reaction according to the concentration of OD 0.440. The culture time of strain fermentation is 18~-22h, the temperature is 30°C, and the rotation speed of the shaker is 160rpm.

[0044] (2) After the cells are cultured, collect the cells by centrifugation, and resuspend the cells in 20ml of phosphate buffer to make the concentration 0.4g DW / mL. Put 5‰ of substrate cholesterol into the conversion solution, and add eutectic to carry out microbial conversion reaction, wherein the added eutectic is choline chloride / ethylene glycol mixed molar ratio of 1:2, 1:1 , 2:1, or the mixed molar ratio of choline chlori...

Embodiment 2

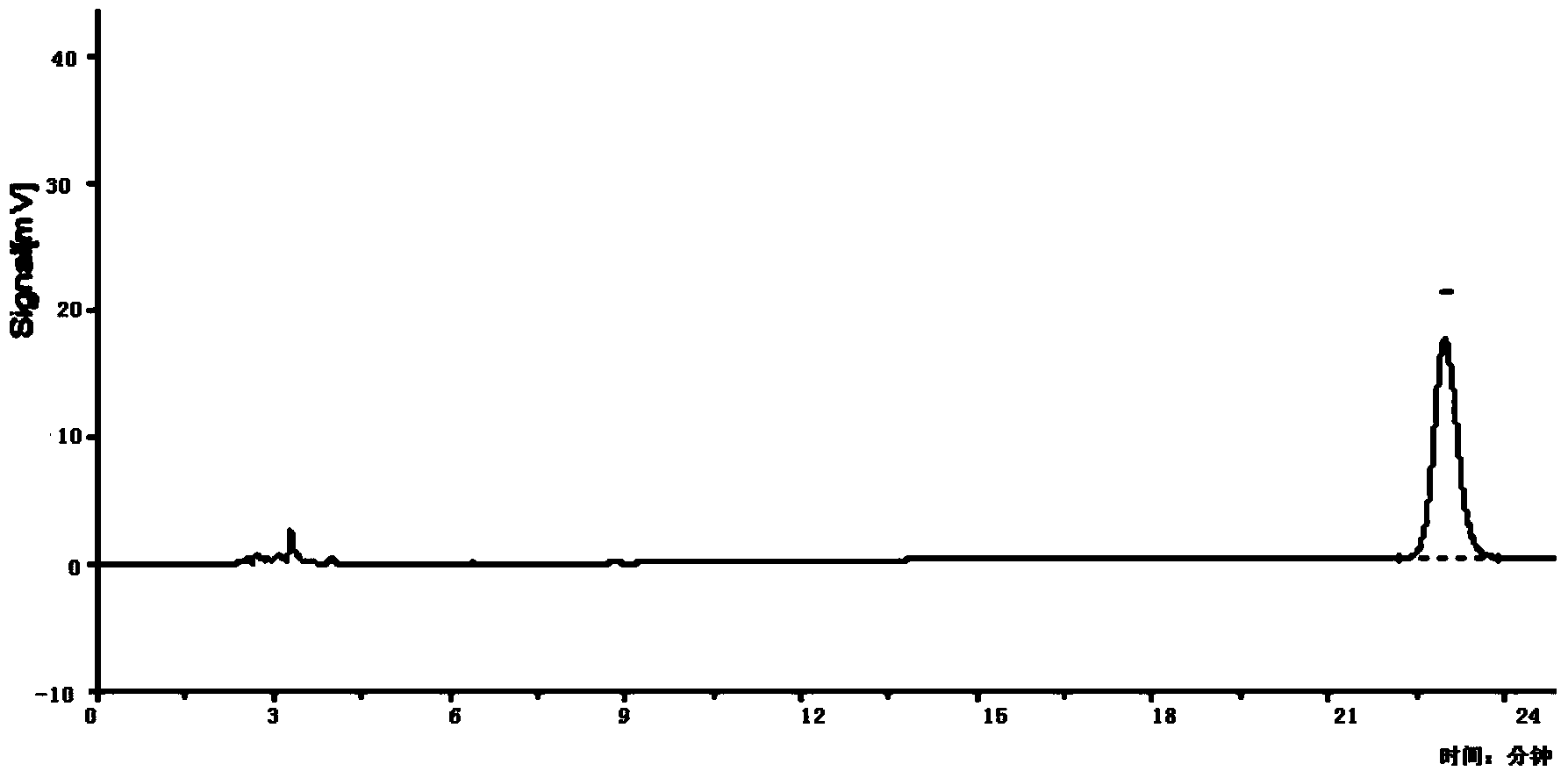

[0050] A method for preparing cholestenone by using eutectic as a solubilizing agent by transforming resting cells. In this embodiment, the catalytic conversion effect of different concentrations of DES is detected by changing the percentage content of DES, as follows:

[0051] ⑴ Scrape Arthrobacter simplex into sterile water, shake and mix well, and add it into a 50ml / 250ml shake flask for reaction according to the concentration of OD 0.440. The culture time of strain fermentation is 18~-22h, the temperature is 30°C, and the rotation speed of the shaker is 160rpm.

[0052] (2) After the bacteria are cultured, collect the bacteria by centrifugation to make the concentration 0.4g DW / mL Use 20ml phosphate buffer to resuspend the cells. Put 5‰ of the substrate cholesterol into the conversion liquid, and add the eutectic choline chloride / urea (molar ratio is 1:1) for conversion, wherein the eutectic solvent accounts for 100% of the DES / phosphate buffer system The component cont...

Embodiment 3

[0055] A method for preparing cholestenone by using eutectic as a solubilizing agent by transforming resting cells. In this embodiment, by changing the substrate concentration, the catalytic conversion effect of the substrate concentration change is detected, as follows:

[0056] ⑴ Scrape Arthrobacter simplex into sterile water, shake and mix well, and add it into a 50ml / 250ml shake flask for reaction according to the concentration of OD 0.440. The culture time of strain fermentation is 18-22h, the temperature is 30°C, and the rotation speed of the shaker is 160rpm.

[0057] (2) After the cells are cultured, collect the cells by centrifugation, and resuspend the cells in 20ml of phosphate buffer to make the concentration 0.4g DW / mL. Put the substrate cholesterol into the conversion liquid, wherein the substrate addition amount is 1‰, 5‰, 1%, 2%, 3%, and add 2% choline chloride / urea (molar ratio is 1:1) low The co-melt undergoes microbial transformation reactions. The conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com