Hydrotalcite-plant cellulose composite pellets and preparation method and application thereof

A plant cellulose, hydrotalcite technology, applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment and other directions, can solve the problems of complex process, difficult recycling work, large engineering, etc., and achieves simple preparation process, Conducive to recycling and easy experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

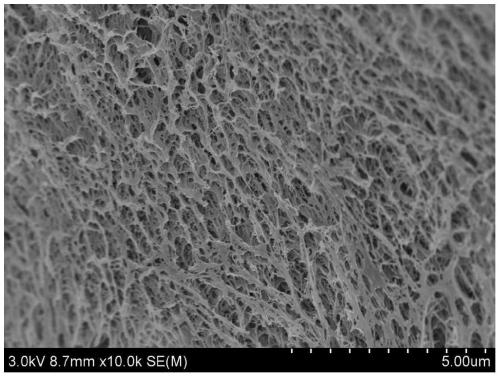

[0059] Embodiment 1 Preparation of hydrotalcite-plant cellulose composite pellets

[0060] Pretreatment and cellulose extraction of royal bamboo grass: cut the royal bamboo grass into small pieces, wash the surface dust with tap water, and finally rinse twice with ultra-pure water, put it into a pot with ultra-pure water and boil for 4 hours, Put it into an oven for drying, grind it with a pulverizer, pass the pulverized sample through a 100-mesh sieve, and place it in a desiccator to dry to constant weight to obtain a powder. Extract cellulose with nitric acid-ethanol method, add the above powder into 250ml of nitric acid ethanol solution (volume ratio of nitric acid ethanol is 1:4) according to the mass-to-liquid ratio of 1g:25ml, install a condensing reflux device, and heat in a water bath at 90°C for 2h , Wash the obtained cellulose powder with nitric acid ethanol solution twice, and then wash with hot water until the washing solution is neutral. The filtrate was sucked d...

Embodiment 2

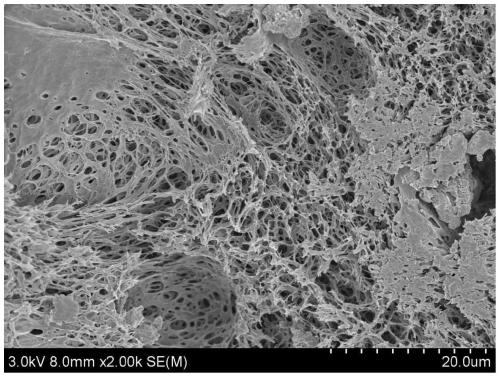

[0064] Embodiment 2 Preparation of hydrotalcite-plant cellulose composite pellets

[0065] Pretreatment and cellulose extraction of royal bamboo grass: cut the royal bamboo grass into small pieces, wash the surface dust with tap water, and finally rinse twice with ultra-pure water, put it into a pot with ultra-pure water and boil for 4 hours, Put it into an oven for drying, grind it with a pulverizer, pass the pulverized sample through a 100-mesh sieve, and place it in a desiccator to dry to constant weight to obtain a powder. Extract cellulose with nitric acid-ethanol method, add the above powder into 250ml of nitric acid ethanol solution (volume ratio of nitric acid ethanol is 1:4) according to the mass-to-liquid ratio of 1g:25ml, install a condensing reflux device, and heat in a water bath at 90°C for 2h. The obtained cellulose powder was rinsed twice with nitric acid ethanol solution, and then washed with hot water until the washing liquid was neutral. The filtrate was su...

Embodiment 3

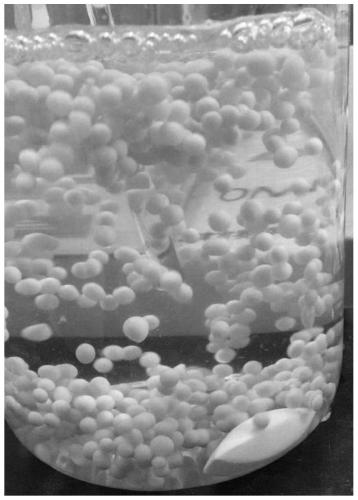

[0069] Example 3 Adsorption Application of Hydrotalcite-Plant Cellulose Composite Beads to Nanoplastics

[0070] Adsorption: Weigh 3 parts (200 pieces each) of the hydrotalcite-plant cellulose composite pellet adsorbent prepared in the above-mentioned Example 1 and add them to 50ml of nanoplastic aqueous solution, shake in a constant temperature oscillator at a constant temperature of 25 degrees for 24 hours The adsorption operation is carried out to test the concentration of the nano-plastic (the main component is polystyrene, the particle size is about 100-200nm) solution. The initial concentration of the prepared nanoplastic solution was 25mg / L, and after 24 hours, it decreased to 8mg / L on average, and the average adsorption rate was 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com