A greening method for rocky slopes in cold regions

A rock and slope technology, applied in the field of ecological restoration, can solve problems such as poor greening effect of slopes and difficulty in planting seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In some technical schemes, the preparation method of water retaining agent comprises:

[0052] Grinding the dried weathered coal to 300 mesh, adding sulfuric acid whose mass is 20%-60% of the pulverized weathered coal and whose concentration is 60-70% to react for 3-5 hours to obtain a flocculent reactant, and then add the flocculent reactant adding humus whose mass is 20-40% of the flocculent reactant, stirring and mixing to obtain the first mixed polymer;

[0053] Use ethyl acetate and / or xylene as a solvent, and add crushed plastic and / or foam to it, dissolve for 24-26 hours, then add starch with a mass of 20-25% of the crushed plastic and / or foam , shearing and emulsifying for 2-3 hours at a rotating speed of 3-35,000 r / min to obtain the second mixed polymer;

[0054] Mix the first mixed polymer and the second mixed polymer with a mass ratio of 1: (0.7-0.9) and then disperse and stir for 2-5 minutes under the condition of 2-25,000 r / min, and then in 1- Dispersing ...

Embodiment 1

[0066] Embodiment 1 water retaining agent and preparation method thereof

[0067] Grinding the dried weathered coal to 300 mesh, adding sulfuric acid with a mass of 20% of the pulverized weathered coal and a concentration of 60 for 3 hours to obtain a flocculent reactant, and then adding a mass of flocculent reactant to the flocculent reactant 20% of the humic substance is stirred and mixed to obtain the first mixed polymer;

[0068] Using ethyl acetate as a solvent, add crushed plastic to it, dissolve it for 24 hours, add starch with a mass of 25% of the crushed plastic, shear and emulsify at a speed of 30,000 r / min for 2 hours, and obtain No. Dimixture;

[0069] Mix the first mixed polymer and the second mixed polymer at a mass ratio of 10:7, then disperse and stir at 20,000 r / min for 2 minutes, and then disperse and stir at 10,000 r / min 6 minutes, obtain the 3rd mixed polymer;

[0070] Mix the third mixed polymer and the inorganic salt mixture at a mass ratio of 5:1 and ...

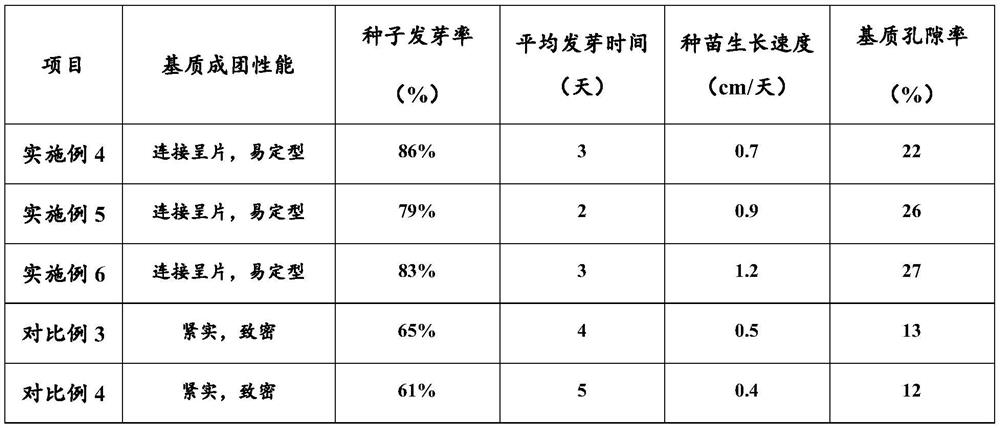

Embodiment 4

[0093] The preparation method of embodiment 4 pellets

[0094] Mix lignin fiber, diatomaceous earth and peat soil according to the weight ratio of 1:80:40;

[0095] Add polyacrylamide twice the mass of lignin fiber to the mixture, add water at 80°C and stir until it becomes a slurry, place the slurry at a temperature of 120°C for 1 hour, and then pulverize it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com