Greening method of rocky slope in cold region

A rock and slope technology, applied in the field of ecological restoration, can solve the problems of difficult seed planting, poor slope greening effect, etc., and achieve the effects of low restoration cost, improved water retention, and overcoming easy landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In some technical schemes, the preparation method of water retaining agent comprises:

[0052] Grinding the dried weathered coal to 300 mesh, adding sulfuric acid whose mass is 20%-60% of the pulverized weathered coal and whose concentration is 60-70% to react for 3-5 hours to obtain a flocculent reactant, and then add the flocculent reactant adding humus whose mass is 20-40% of the flocculent reactant, stirring and mixing to obtain the first mixed polymer;

[0053] Use ethyl acetate and / or xylene as a solvent, and add crushed plastic and / or foam to it, dissolve for 24-26 hours, then add starch with a mass of 20-25% of the crushed plastic and / or foam , shearing and emulsifying for 2-3 hours at a rotating speed of 3-35,000 r / min to obtain the second mixed polymer;

[0054] Mix the first mixed polymer and the second mixed polymer with a mass ratio of 1: (0.7-0.9) and then disperse and stir for 2-5 minutes under the condition of 2-25,000 r / min, and then in 1- Dispersing ...

Embodiment 1

[0066] Embodiment 1 water retaining agent and preparation method thereof

[0067] Grinding the dried weathered coal to 300 mesh, adding sulfuric acid with a mass of 20% of the pulverized weathered coal and a concentration of 60 for 3 hours to obtain a flocculent reactant, and then adding a mass of flocculent reactant to the flocculent reactant 20% of the humic substance is stirred and mixed to obtain the first mixed polymer;

[0068] Using ethyl acetate as a solvent, add crushed plastic to it, dissolve it for 24 hours, add starch with a mass of 25% of the crushed plastic, shear and emulsify at a speed of 30,000 r / min for 2 hours, and obtain No. Dimixture;

[0069] Mix the first mixed polymer and the second mixed polymer at a mass ratio of 10:7, then disperse and stir at 20,000 r / min for 2 minutes, and then disperse and stir at 10,000 r / min 6 minutes, obtain the 3rd mixed polymer;

[0070] Mix the third mixed polymer and the inorganic salt mixture at a mass ratio of 5:1 and ...

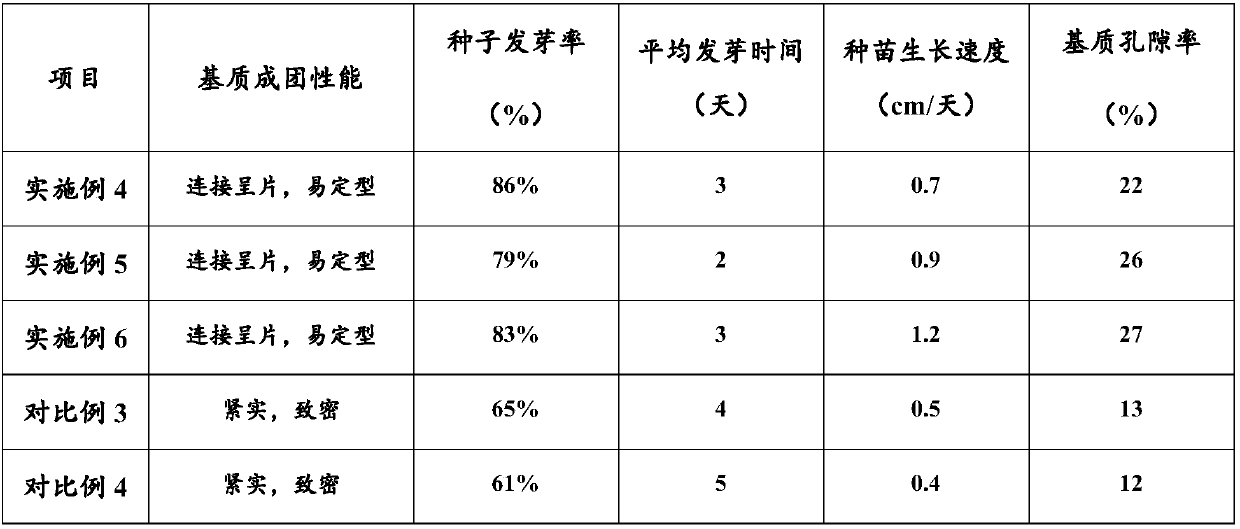

Embodiment 4

[0093] The preparation method of embodiment 4 pellets

[0094] Mix lignin fiber, diatomaceous earth and peat soil according to the weight ratio of 1:80:40;

[0095] Add polyacrylamide twice the mass of lignin fiber to the mixture, add water at 80°C and stir until it becomes a slurry, place the slurry at a temperature of 120°C for 1 hour, and then pulverize it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com