A kind of nitride led manufacturing method based on metal mask substrate

A metal mask and manufacturing method technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as increasing device leakage current, device damage, affecting device light extraction efficiency, performance and stability, and improving heat dissipation. performance, improved crystal quality, strong absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

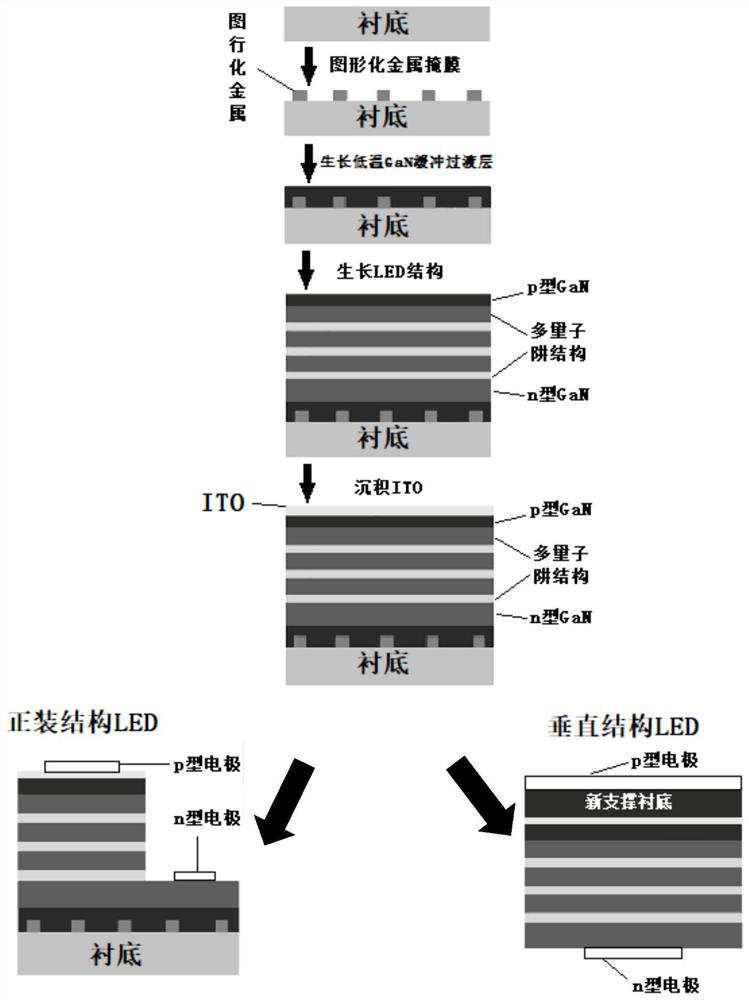

[0049] Embodiment 1: The preparation of front-mounted c-plane LED, see figure 2 .

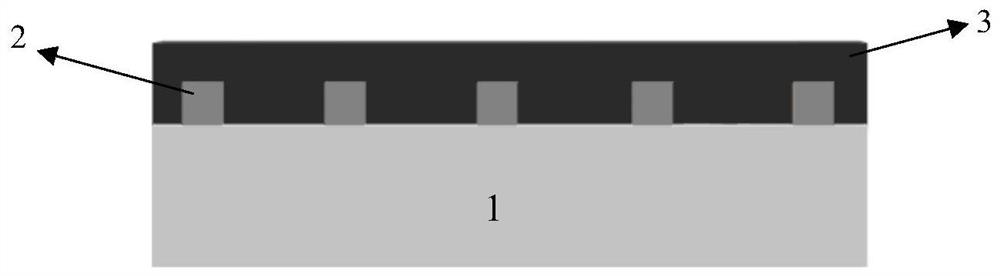

[0050] 1. The substrate can be sapphire, silicon carbide, Si and other substrates. Using photolithography technology, a patterned photoresist with an opening size of 1-500 μm and a duty ratio (without photoresist: with photoresist) of 1: (10-1) is formed on the substrate. The pattern can be: Long rectangles, regular hexagons or circles, etc., the single-layer patterns can be arranged in an equiperiod arrangement or a disordered arrangement; then magnetron sputtering technology is used to deposit a metal with a melting point greater than 1000°C on the substrate, with a thickness of In 10 ~ 150nm. The patterned metal layer can be a single layer or multiple layers, and the pattern direction and deposition thickness of each layer can be designed according to needs. After the metal deposition is completed, the photoresist is removed by using acetone or other solutions that can remove the photore...

Embodiment 2

[0060] Example 2: Preparation of c-plane vertical structure LED:

[0061]1. The substrate can be sapphire, silicon carbide, Si and other substrates. Using photolithography technology, a patterned photoresist with an opening size of 1-500 μm and a duty ratio (without photoresist: with photoresist) of 1: (10-1) is formed on the substrate. The pattern can be: Long rectangles, regular hexagons or circles, etc., the single-layer patterns can be arranged in an equiperiod arrangement or a disordered arrangement; then magnetron sputtering technology is used to deposit a metal with a melting point greater than 1000°C on the substrate, with a thickness of In 10 ~ 150nm. The patterned metal layer can be a single layer or multiple layers, and the pattern direction and deposition thickness of each layer can be designed according to needs. After the metal deposition is completed, the photoresist is removed by using acetone or other solutions that can remove the photoresist without damagin...

Embodiment 3

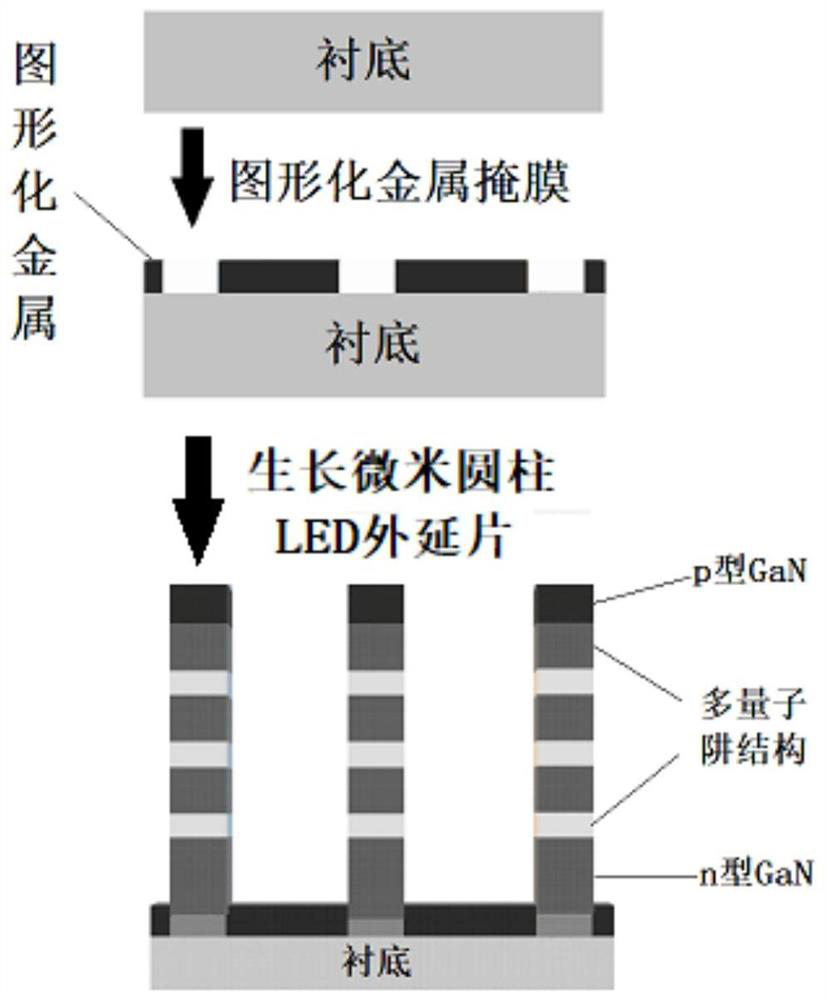

[0075] Embodiment 3: Preparation of micro-cylindrical LED epitaxial wafer:

[0076] 1. The substrate can be sapphire, silicon carbide, Si and other substrates. Using photolithography technology, a patterned photoresist with an opening size of 100nm to 10μm and a duty ratio (with photoresist: without photoresist) of 1: (10~1) is formed on the substrate. The pattern can be: Long rectangles, regular hexagons or circles, etc., the single-layer patterns can be arranged in an equiperiod arrangement or a disordered arrangement; then magnetron sputtering technology is used to deposit a metal with a melting point greater than 1000°C on the substrate, with a thickness of In the range of 10-150nm, the pattern direction and deposition thickness of each layer can be designed according to needs. After the metal deposition is completed, the photoresist is removed by using acetone or other solutions that can remove the photoresist without damaging the epitaxial wafer, and ultrasonic cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com