Ultrasonic suspension conveying device capable of achieving multi-excitation large loads

A transmission device, large load technology, applied in transportation and packaging, conveyors, non-mechanical conveyors and other directions, can solve the problems of inability to achieve long-distance transmission, low efficiency, system instability, etc., to avoid heating and shortening. Axial dimension, effect of reducing acoustic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

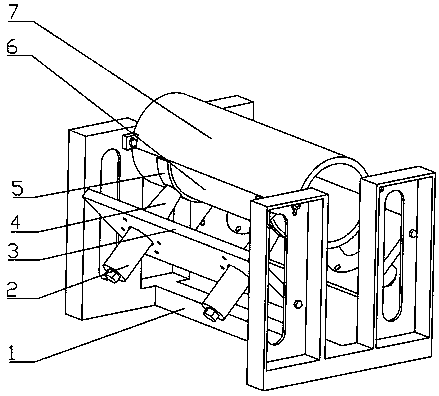

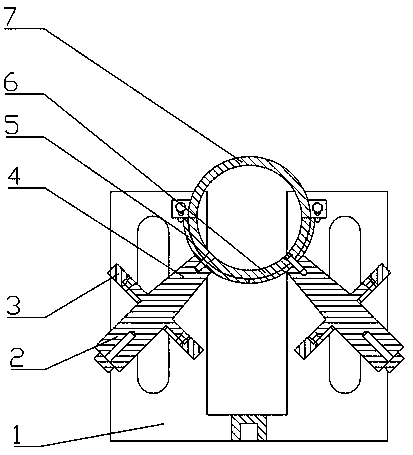

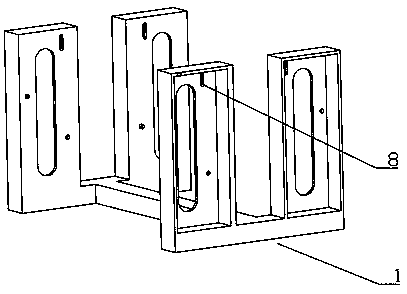

[0033] Example: see Figure 1-Figure 9 , in the figure, 1-outer frame, 2-ultrasonic transducer, 3-fixed horizontal plate, 4-ultrasonic horn, 5-supporting plate, 6-semicircular transmission plate, 7-semicircular reflector, 8- Height adjustment slot, 9-reflection end, 10-piezoelectric ceramic sheet, 11-high-strength external hexagonal bolt, 12-flange positioning slot, 13-first-level horn, 14-second-level horn, 15-method Lan, 16-locking groove.

[0034] The ultrasonic levitation transmission device that can realize multiple excitations and large loads has a technical solution: the ultrasonic levitation transmission device includes an external frame, an ultrasonic vibration mechanism, a fixed horizontal plate, a supporting plate, a semicircular transmission plate and a semicircular reflector, and an ultrasonic power supply.

[0035] The outer frame 1 and the fixed horizontal plate 3, the outer frame adopts an I-shaped base, and its upper end is provided with four height adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com