Method for repairing oil-contaminated soil through reinforcement of biochar-base complex microbial inoculant

A compound bacterial agent, oil pollution technology, applied in the restoration of polluted soil and other directions, can solve the problems of slow growth of oil-degrading microorganisms, reduced survival rate, resource consumption, etc., and achieves easy control of process parameters, guaranteed degradation efficiency, and degradation quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (1) Preparation of biochar-based composite bacterial agent: using biochar as a carrier, mycobacterium CSC-6 bacterial liquid was prepared by adsorption method; the preservation number of mycobacterium CSC-6 is CCTCC No: M 2017726, a typical culture in China Preserved by the preservation center, the preservation date is November 27, 2017; biochar can be one or a mixture of rice husks, cotton stalks, japonica rice or rattan.

[0034] (2) Preparation of biosurfactant: with mannitol as carbon source, Pseudomonas aeruginosa W-3 is fermented and cultivated to obtain a fermentation broth containing biosurfactant, which is rhamnolipid ; The preservation number of Pseudomonas aeruginosa W-3 is CCTCC NO:M2010048, which was preserved in China Center for Type Culture Collection, and the preservation date was March 05, 2010.

[0035] (3) Conservation of polluted soil: the polluted soil is crushed, and the polluted soil is sieved with a fineness greater than 10 mesh sampling sieves, ...

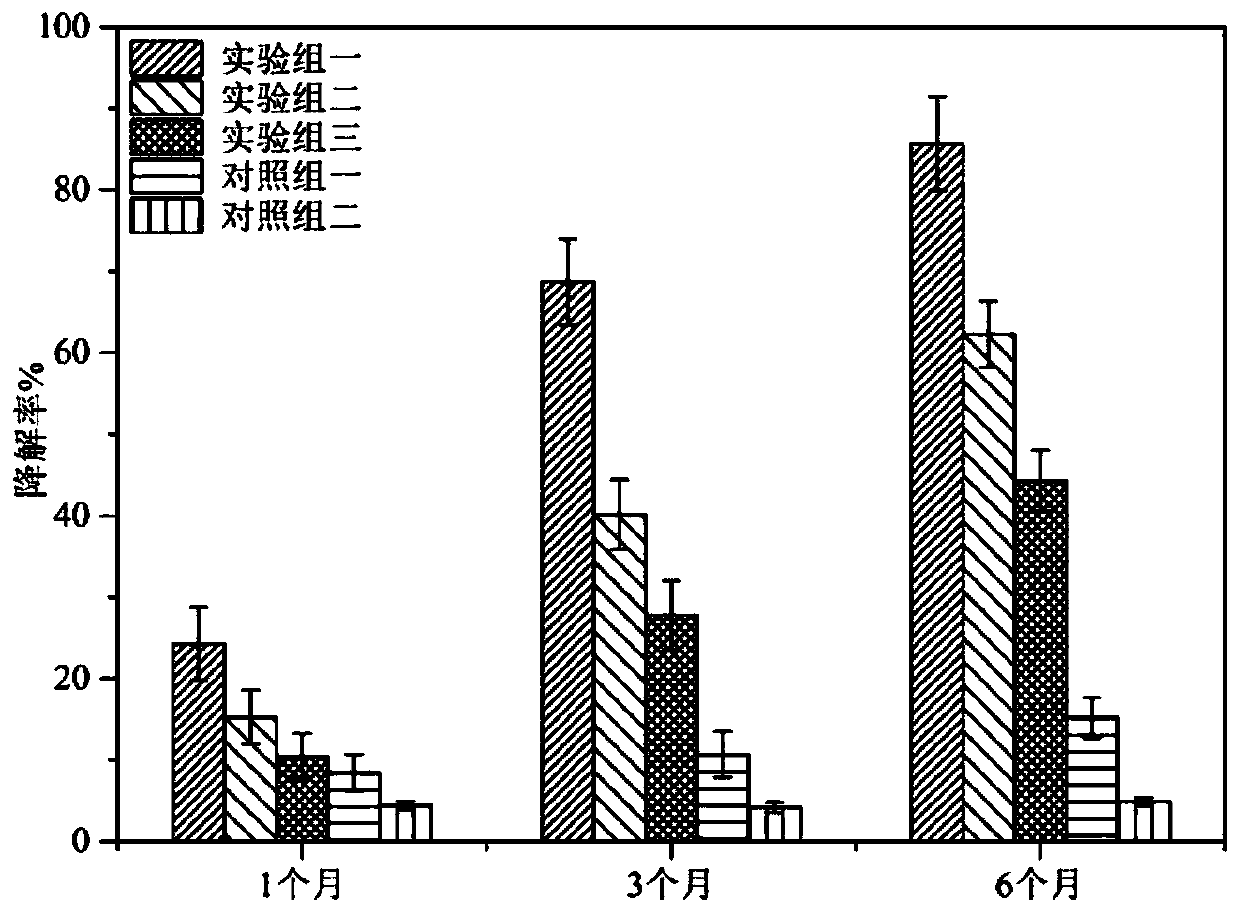

Embodiment 1

[0041] In this embodiment, the method of strengthening and repairing oil-contaminated soil with a biochar-based composite bacterial agent is used to treat fresh oil-contaminated soil. The test method is as follows:

[0042] (1) Collect unpolluted fresh soil, pass through a 10-mesh sieve after crushing, add petroleum to make the oil content be 30000mg / kg, and obtain the fresh petroleum-contaminated soil that the oil content is 30000mg / kg;

[0043] (2) Using biochar as a carrier, prepare mycobacterium CSC-6 bacterium liquid by adsorption method, wherein the mass fraction of mycobacterium CSC-6 is 1%, and biochar is selected from rice husk charcoal; with mannitol as carbon source, the Pseudomonas aeruginosa W-3 is fermented and cultured to obtain a fermentation liquid containing a biosurfactant, and diluted with water to obtain a dilution of a fermentation liquid containing a biosurfactant, wherein the biosurfactant is rhamnolipid, and fermented with a biosurfactant The mass frac...

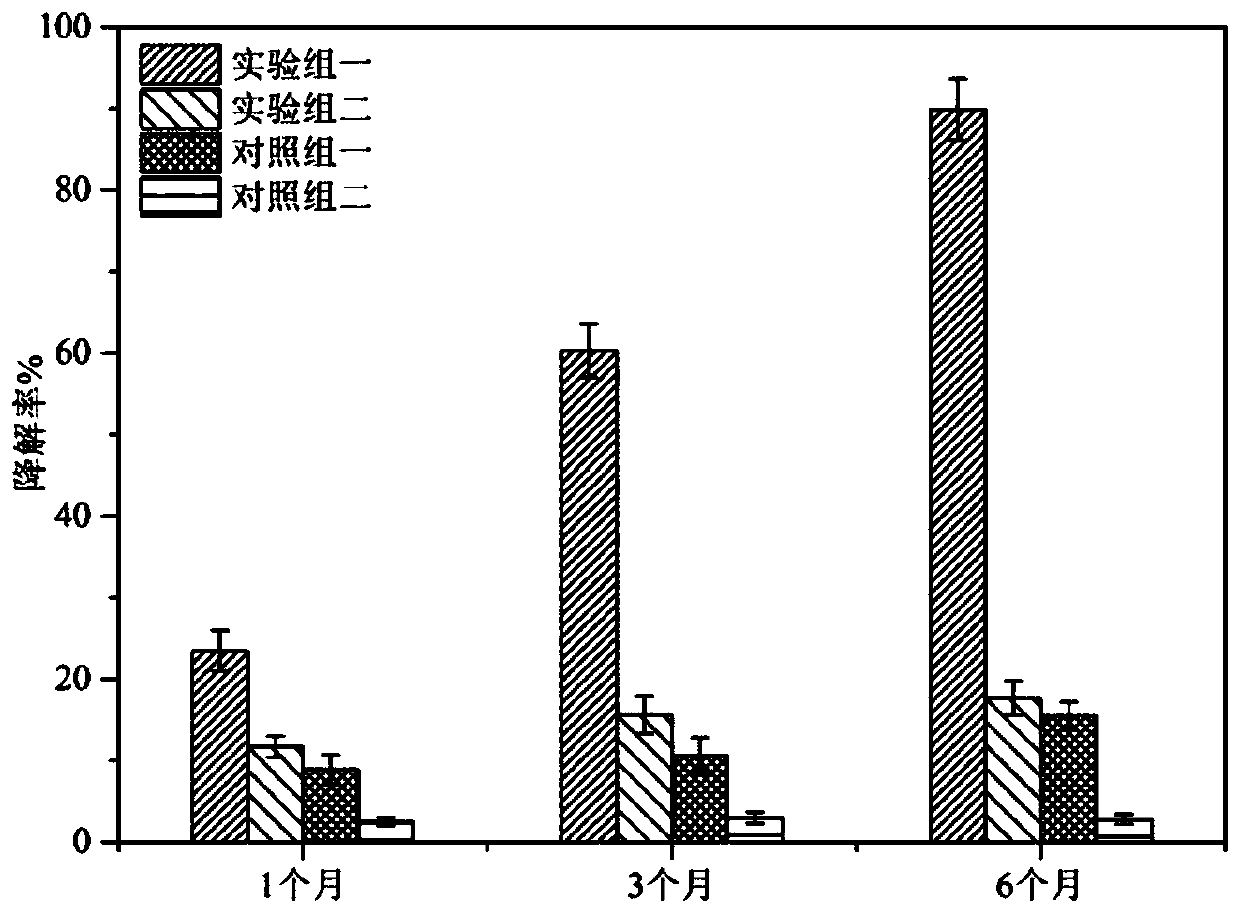

Embodiment 2

[0048] In this embodiment, the method of strengthening and repairing oil-contaminated soil with a biochar-based composite bacterial agent is used to treat fresh oil-contaminated soil. The test method is as follows:

[0049] (1) Collect unpolluted fresh soil, pass through a 10-mesh sieve after crushing, add petroleum to make the oil content be 50000mg / kg, and obtain the fresh petroleum-contaminated soil that the oil content is 50000mg / kg;

[0050] (2) Using biochar as a carrier, prepare mycobacterium CSC-6 bacterium liquid by adsorption method, wherein the mass fraction of mycobacterium CSC-6 is 1%, and biochar is selected from rice husk charcoal; with mannitol as carbon source, the Pseudomonas aeruginosa W-3 is fermented and cultured to obtain a fermentation liquid containing a biosurfactant, and diluted with water to obtain a dilution of a fermentation liquid containing a biosurfactant, wherein the biosurfactant is rhamnolipid, and fermented with a biosurfactant The mass frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com