Large-length-diameter-ratio nut inverted planetary roller screw

A planetary roller, large aspect ratio technology, used in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problem that the structural advantages of the reversed planetary roller screw cannot be fully utilized, and the reversed planetary The nut length, thread structure parameters, and accuracy grade of the roller screw are difficult to guarantee, so as to achieve the effect of high bearing capacity, lower production cost, and strong impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

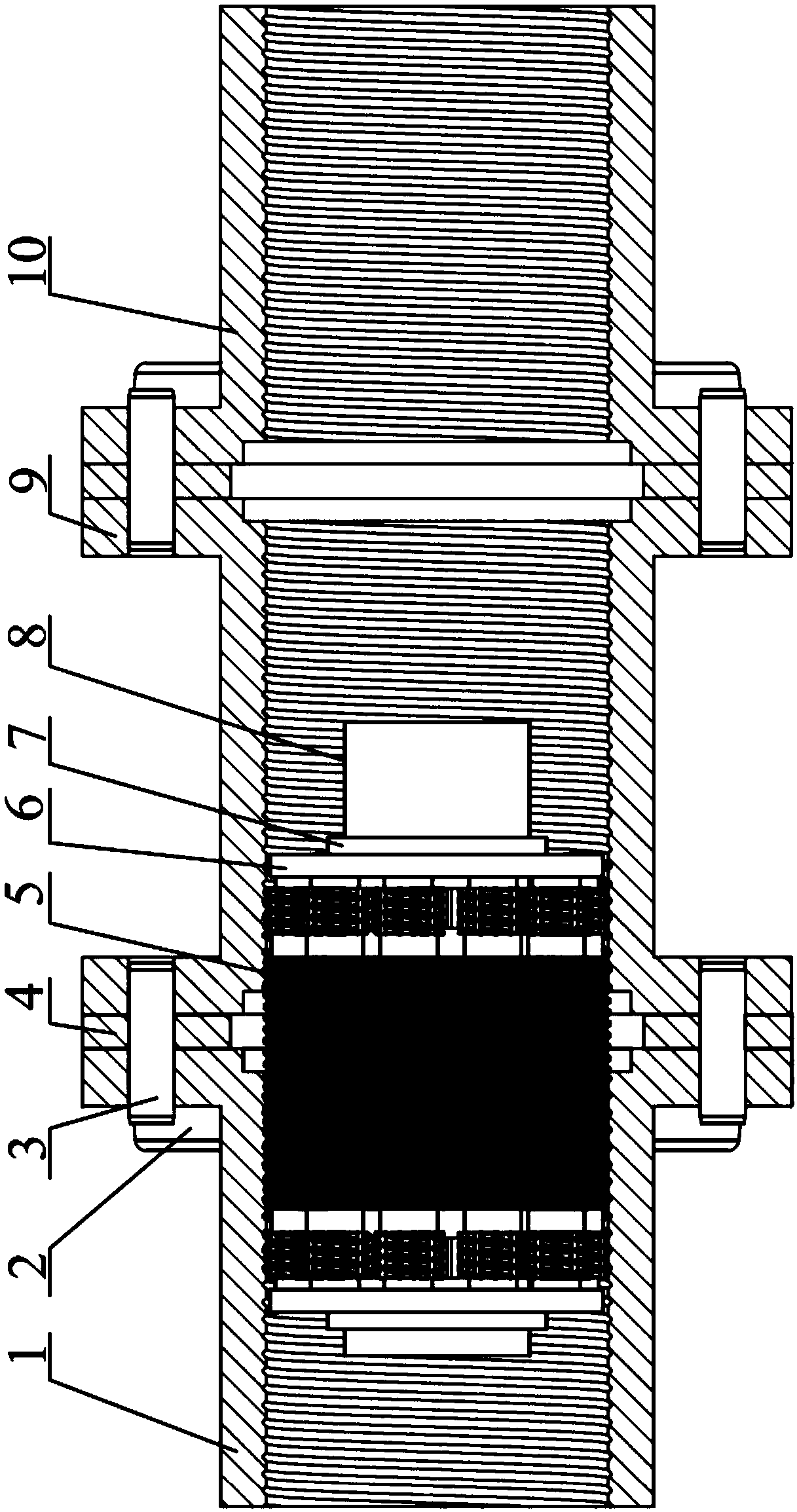

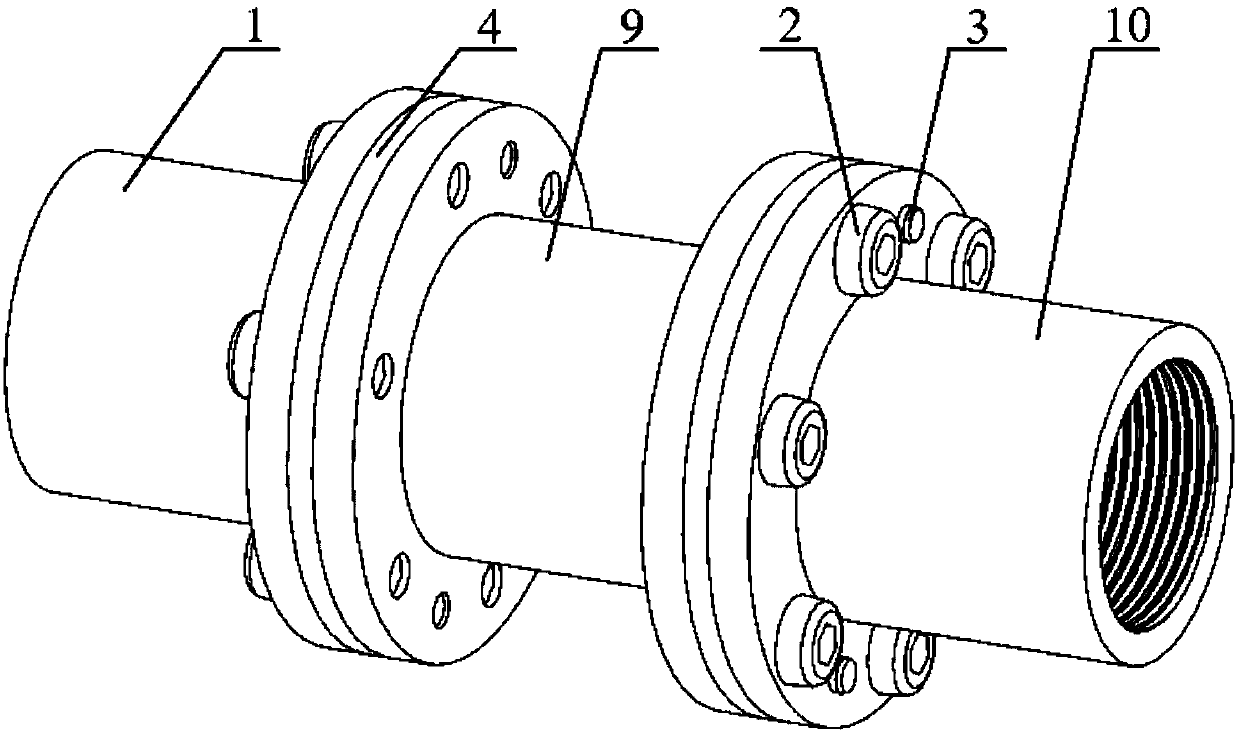

[0023] Embodiment one: if Figure 1-5 As shown, a large length-to-diameter ratio nut reverse planetary roller screw involved in this embodiment includes a nut a, a hexagon socket head cap screw, a cylindrical pin, an adjusting washer, a planetary roller, and a roller cage , Shaft circlip, screw, nut b and nut c, rollers, roller cages, shaft circlips and screw are all set in nut a, nut b and nut c; planetary rollers along the circumference The direction is evenly set between nut a, nut b, nut c and the screw rod, and the two ends of the planetary roller are the roller cage and the elastic retaining ring for the shaft in turn; the screw rod is coaxially set between the nut a, nut b, nut In c, the screw rod is provided with multi-head external threads, and the two ends of the screw rod are provided with involute gears; one end of nut a and nut c has flanges, and both ends of thread b have flanges, and the flanges There are threaded holes equidistantly distributed along the circu...

Embodiment 2

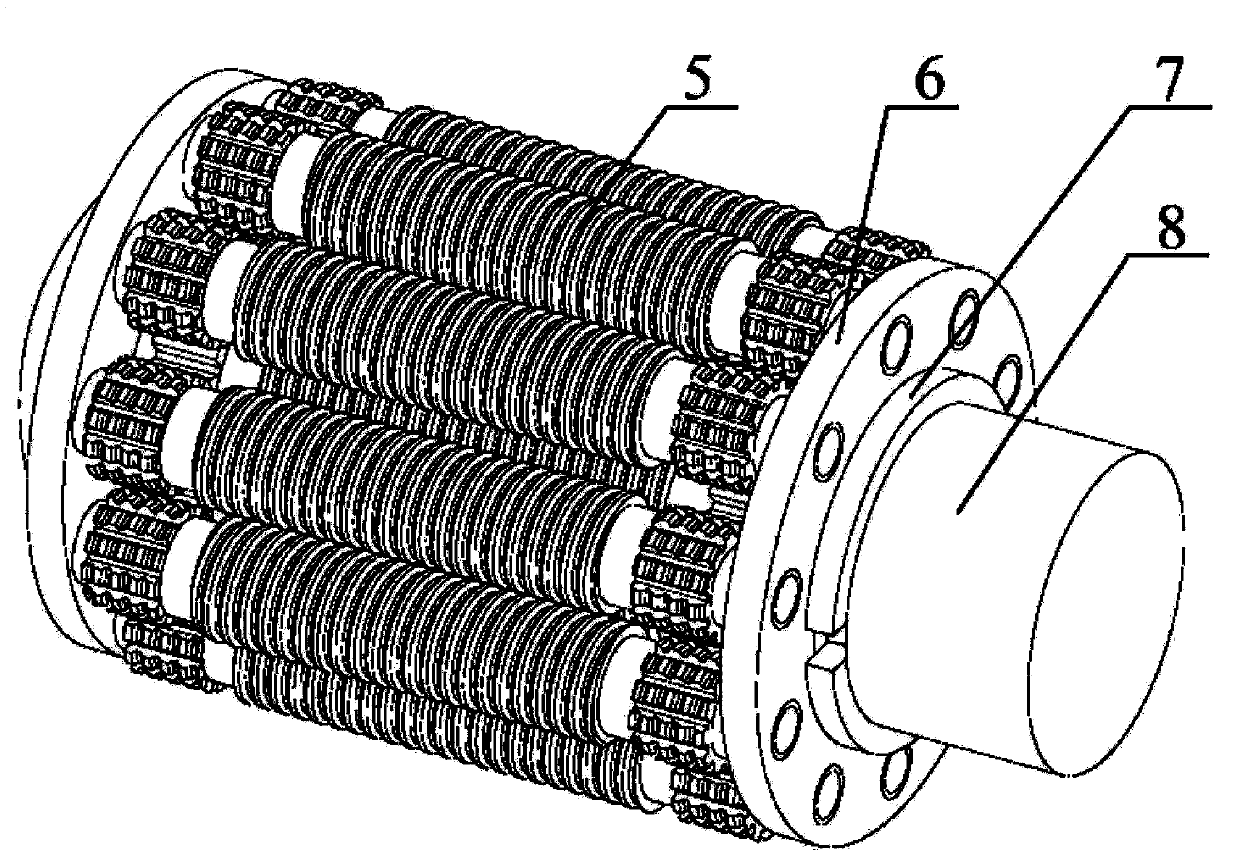

[0025] Embodiment two: if figure 1 , 2 As shown in and 5, a large aspect ratio nut reverse planetary roller screw involved in this embodiment, the plurality of planetary rollers are evenly arranged on the screw rod and nut a, nut b, nut Between c, a planetary thread transmission mechanism is formed; the plurality of planetary rollers are all provided with single-threaded threads that mesh with the multi-headed external threads on the screw rod, and both ends of the planetary rollers have cylindrical optical axes and involutes Gears, the optical axes at both ends of the planetary rollers are respectively connected to the inner holes of the roller cages at both ends of the planetary rollers along the circumferential direction, the gears at both ends of the planetary rollers mesh with the upper gear of the screw, and the The gear transmission ratio is the same as the number of heads of the multi-start external thread of the screw rod and the number of heads of the planetary roll...

Embodiment 3

[0027] Embodiment three: as figure 1 and 3 As shown in the present embodiment, a large length-to-diameter ratio nut reverse type planetary roller screw, the nut a, nut b, and nut c are all provided with the same number of threads as the multi-head external threads on the screw rod. Multi-start internal threads, nut a, nut b, nut c cooperate with single-start external threads of a plurality of planetary rollers to form thread pair transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com