Downhole dust removal method

A technology of underground ventilation and bubbles, which is applied in dust prevention, earth square drilling, mining equipment, etc., can solve the problems of poor dust removal effect and achieve good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

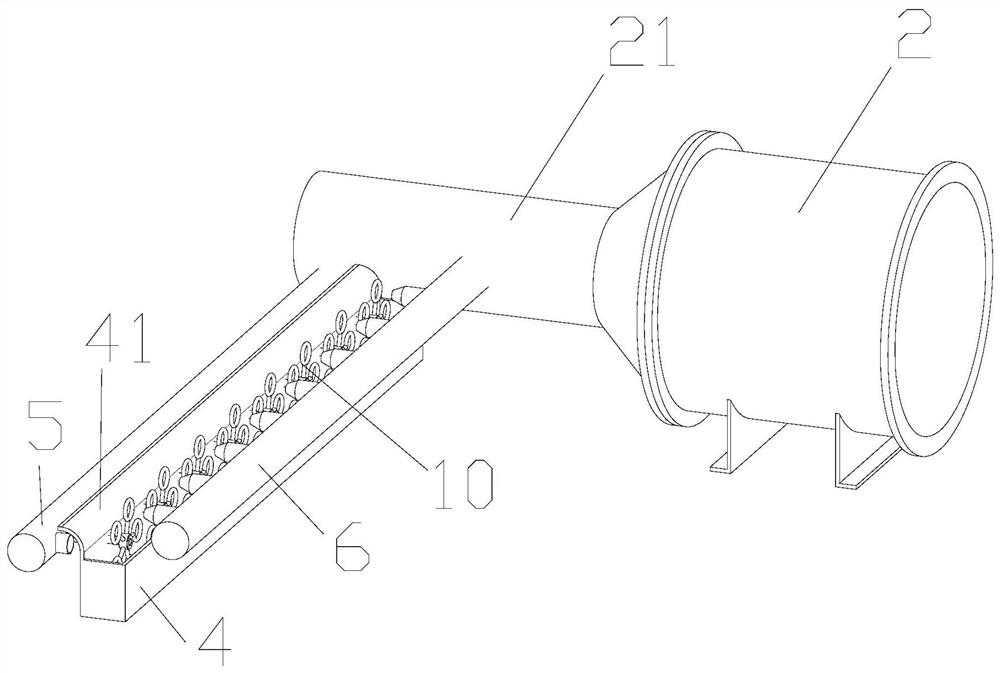

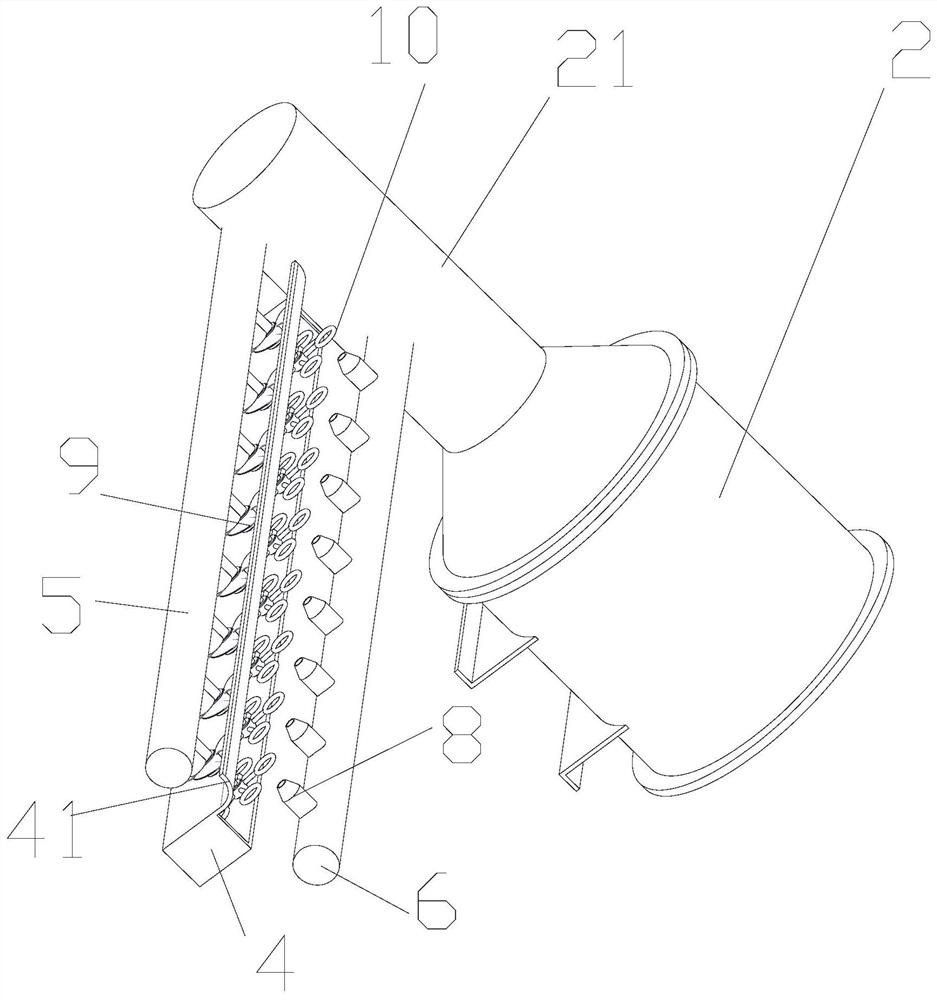

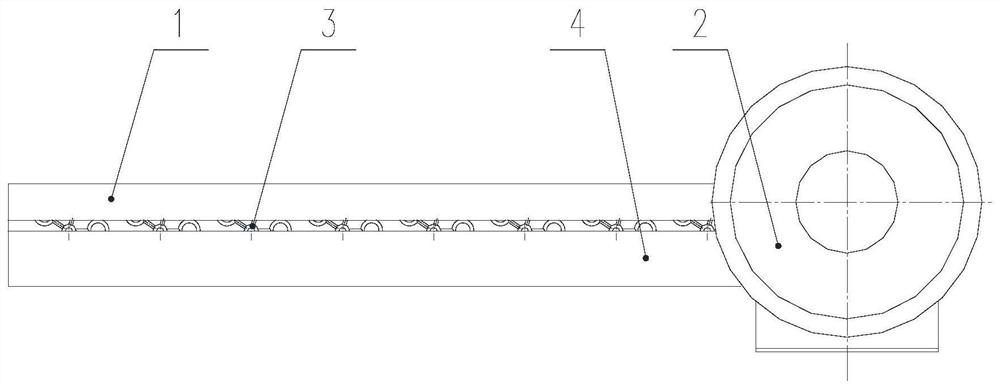

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, downhole dedusting method of the present invention comprises:

[0031] Step A: Continuously generate bubbles with a foaming device downhole;

[0032] Step B: draw the wind for blowing bubbles from the blower 2 for downhole ventilation;

[0033] Step C: Use the wind for blowing bubbles to blow out and diffuse the bubbles continuously generated by the foaming device, and use the blown bubbles to remove dust down the well.

[0034] Further, the wind for blowing bubbles is drawn from the side of the air blower 2, so that the normal ventilation function of the air blower is not affected.

[0035] Further, in step A, wind power is used as the power of the foaming device to reduce power cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com