A high slump retarding polycarboxylate superplasticizer and its preparation and application

A technology of retarding polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures, can solve the problems of poor slump retention, etc., and achieve the effects of improving construction workability, long-term dispersion retention, and improving loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

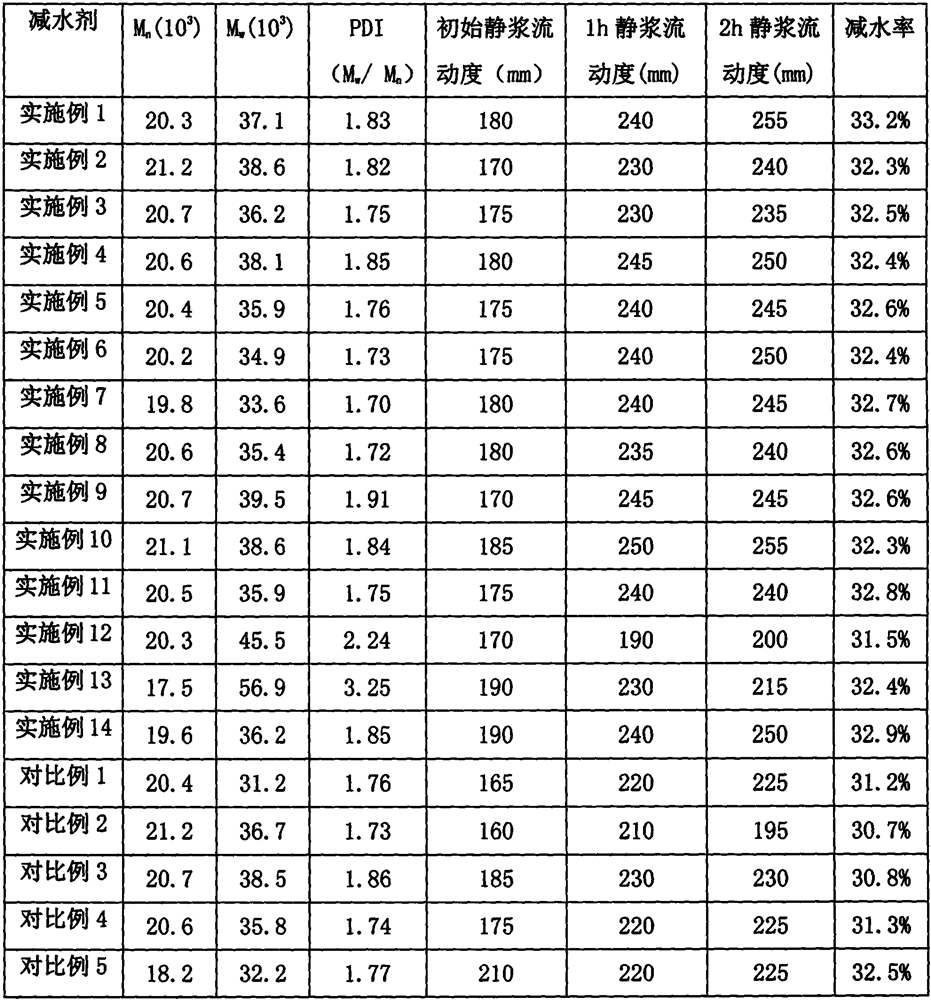

Examples

Embodiment 1

[0029] Add a certain amount of acrylic acid, methyl acrylate, sodium acrylate, polyethylene glycol diacrylate, methallyl alcohol polyoxyethylene ether (HPEG, number average molecular weight 2400), acrylamide into a 500mL flask equipped with a stirrer. (AM), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 2-acrylamido-2-phenylethanesulfonic acid (AMSS) and deionized water, heated to 50 ° C, stirred to make all the raw materials Dissolve, heat up to 70°C, add initiator sodium persulfate and chain transfer agent mercaptoacetic acid dropwise, add dropwise for 3 hours, keep warm for 1 hour, cool to room temperature after the reaction, and neutralize with NaOH solution to obtain the product polycarboxylic acid Water reducing agent.

[0030] Wherein the amount of each raw material is 0.5mol acrylic acid, 0.2mol methyl acrylate, 0.1mol sodium acrylate, 0.1mol polyethylene glycol (PEG400) diacrylate, 0.05mol methallyl alcohol polyoxyethylene ether (HPEG), 0.3mol Acrylamide (AM), 0.1...

Embodiment 2

[0032] The unsaturated polyether macromonomer was changed to allyl polyoxyethylene ether (APEG, number average molecular weight 1800), and the others were the same as in Example 1.

Embodiment 3

[0034] The unsaturated polyether macromonomer was changed to isopentenol polyoxyethylene ether (TPEG, number average molecular weight 2500), and the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com