Self-repairing grouting material and preparation method thereof

A grouting material and self-repairing technology, which is applied in the field of concrete, can solve problems such as detachment, affecting the stability of prefabricated building structures, and damage the joints between grouting materials and steel bars, so as to achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

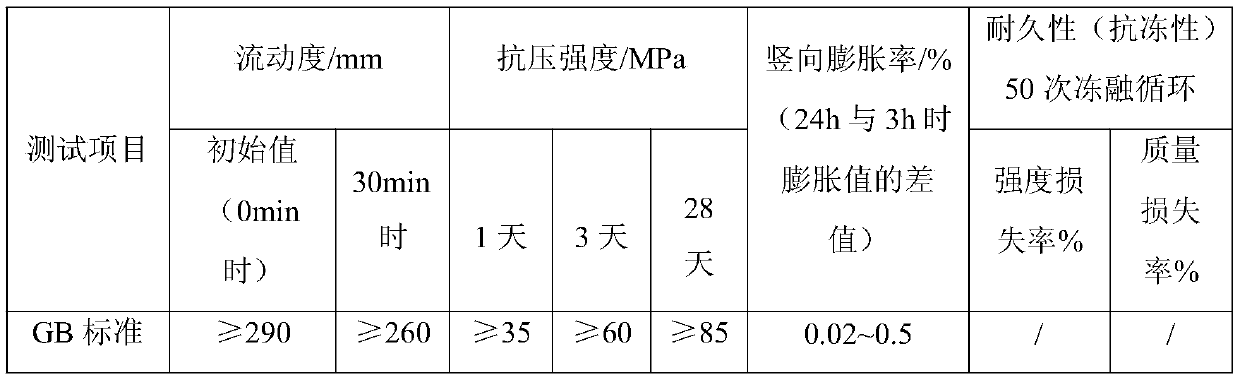

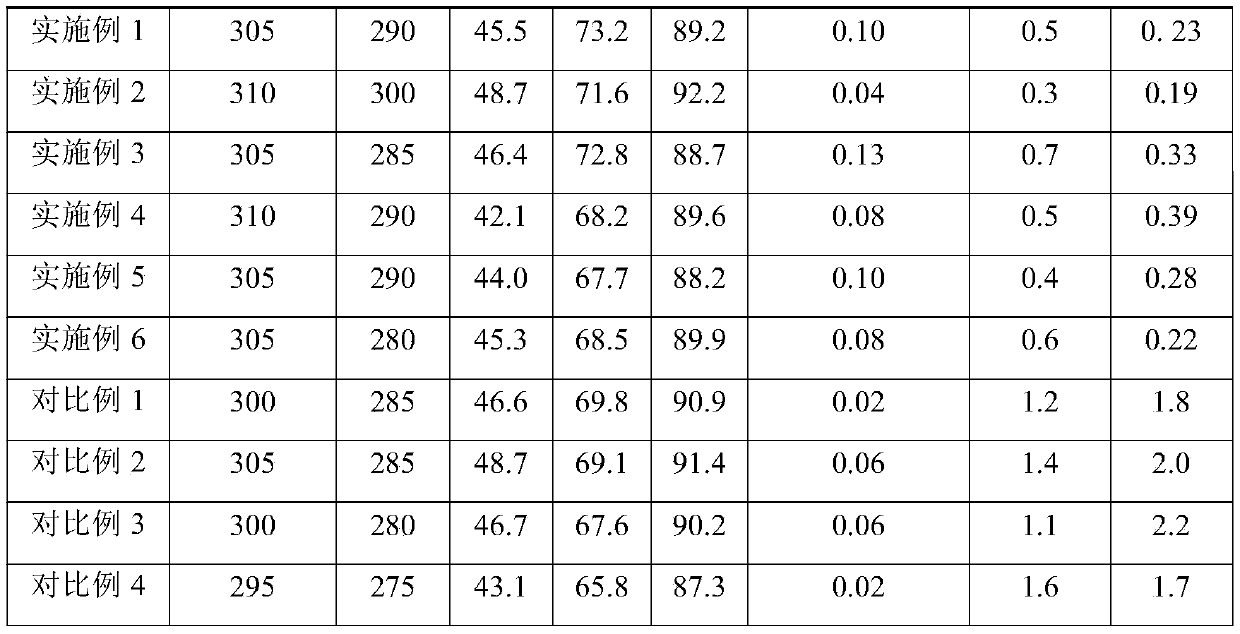

Examples

Embodiment 1

[0030] A self-repairing grouting material, prepared by mixing grouting powder and water, the grouting powder is calculated by preparing 100kg of self-repairing grouting material, including the following raw material components: 45kg of cementitious material, 10kg of micro-aggregate , 40kg of fine aggregate, 0.05kg of admixture and 4.95kg of self-healing agent.

[0031] The self-healing agent includes 1.5kg self-healing capsule, 2kg catalyst and 1.45kg magnesium oxide.

[0032] The self-repairing capsule includes a chemical repairing agent for repairing cracks and a capsule shell for wrapping the chemical repairing agent. The capsule shell is made of a polymer membrane material, wherein the polymer membrane material is polymethacrylic acid glycidol ester, the chemical restoration agent and the catalyst undergo a polymerization reaction.

[0033] The chemical restoration agent is epoxy propylene silicone resin, and the catalyst is sebacic acid dihydrazide.

[0034] The cementi...

Embodiment 2

[0045] The difference from Example 1 is that the self-healing agent includes 2.5kg self-healing capsule, 2kg catalyst and 0.45kg magnesium oxide.

Embodiment 3

[0047] The difference from Example 1 is that the self-healing agent includes 1.5kg self-healing capsule, 1.5kg catalyst and 1.95kg magnesium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com