High-speed roadway concrete stirring construction device

A technology for construction devices and highways, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as large energy consumption, uneven mixing, long waiting time, etc., achieve good results, reduce waste, The effect of reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

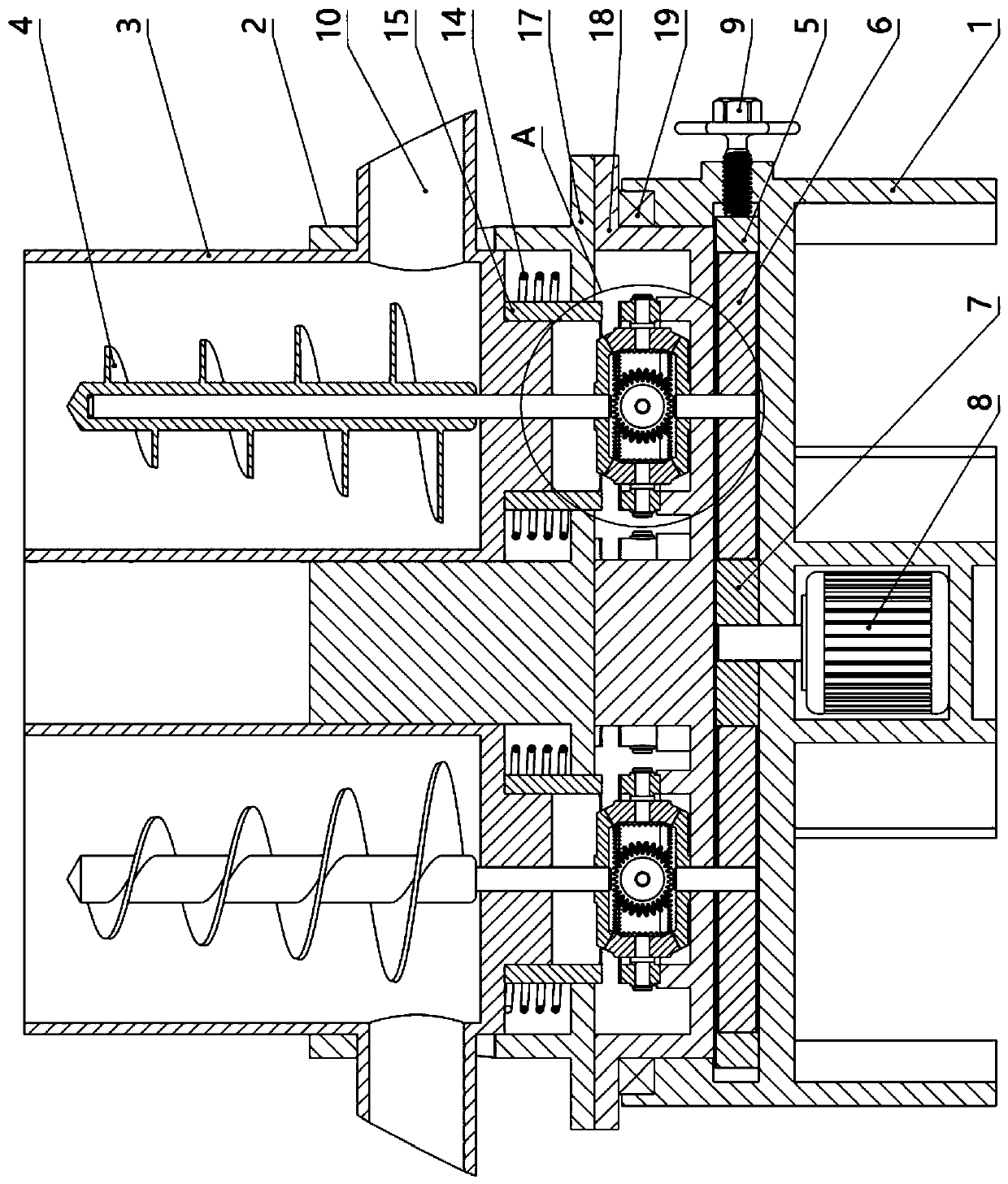

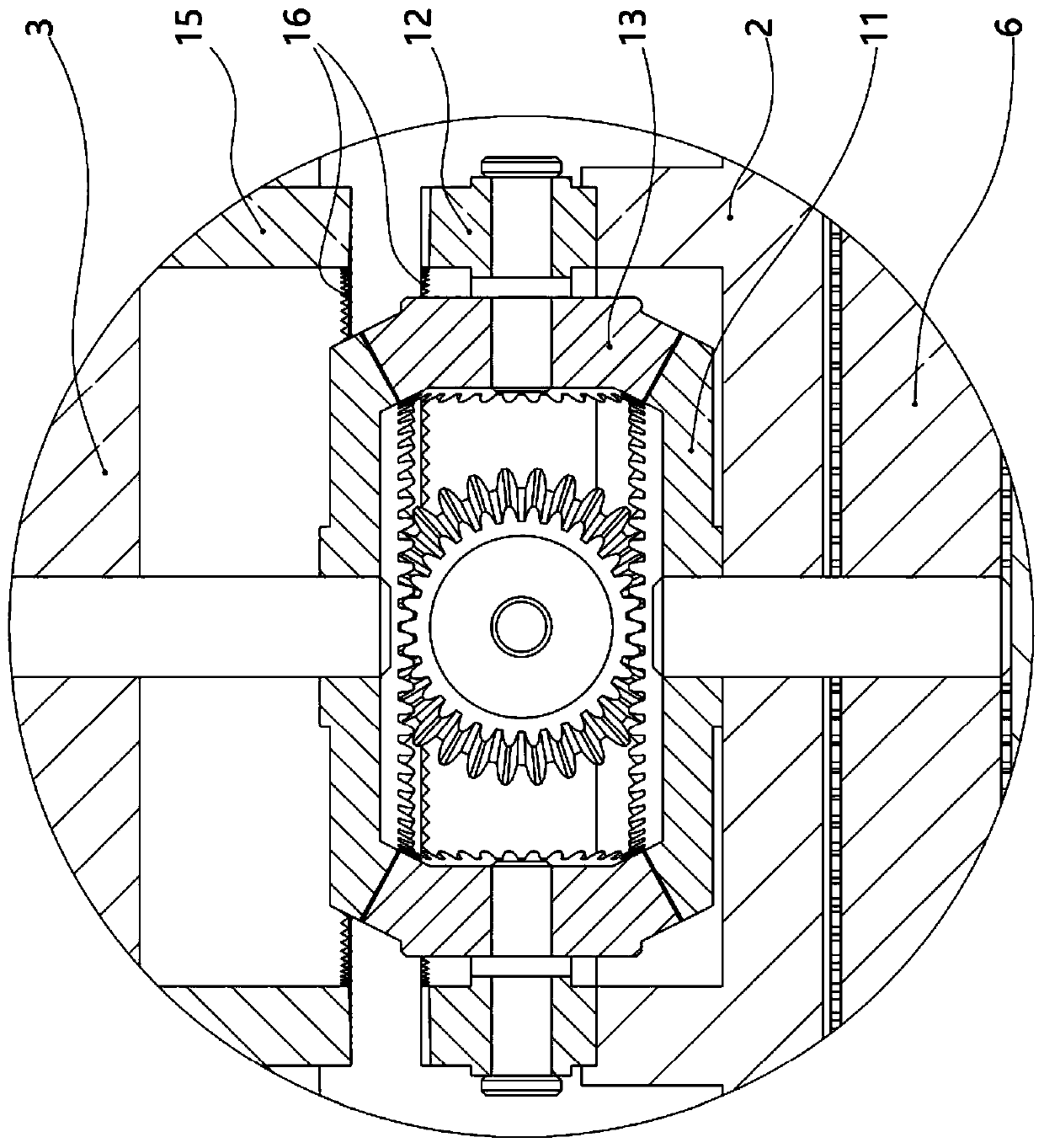

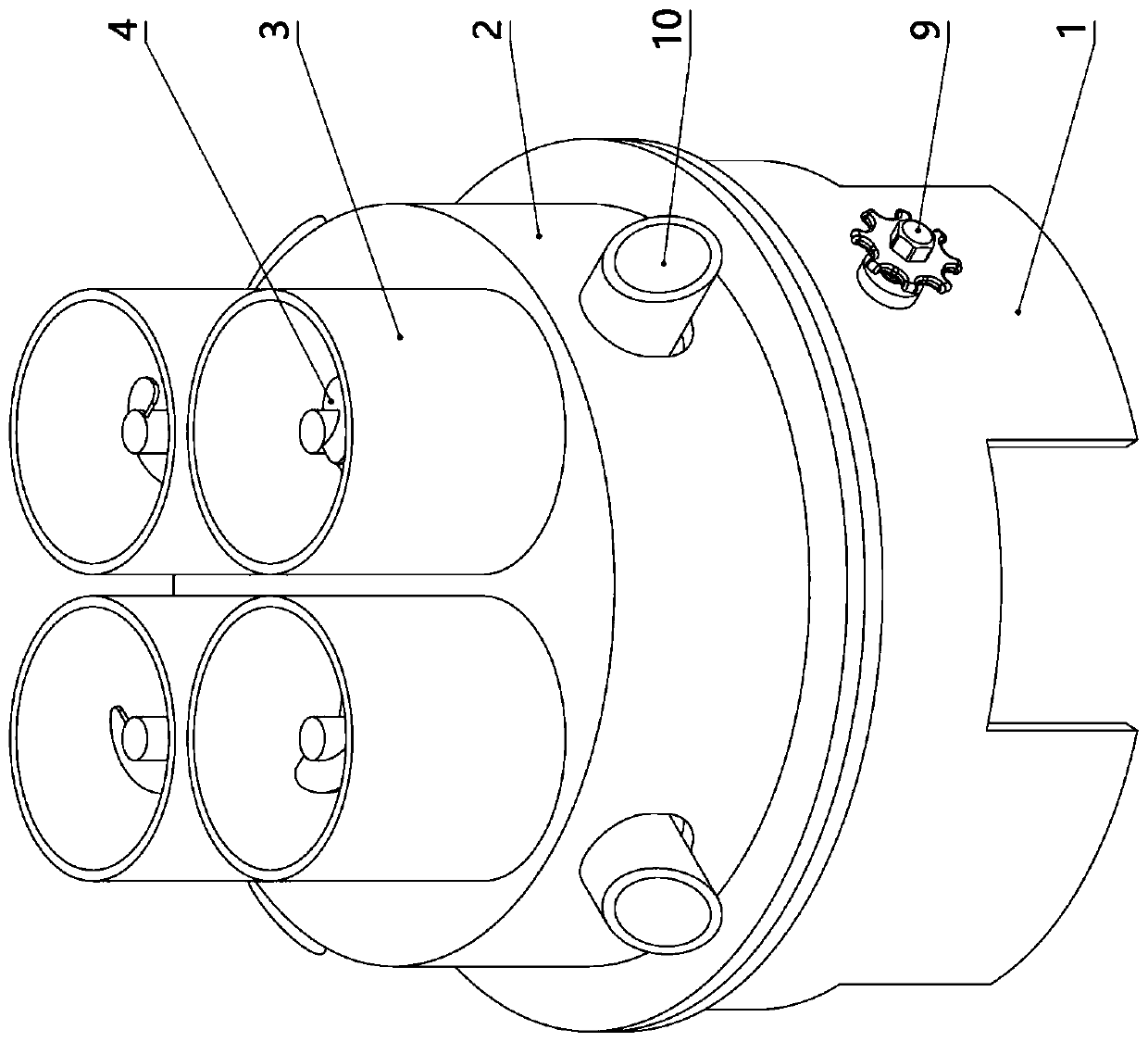

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Depend on Figure 1 to Figure 4 Given, the present invention comprises a base 1, a rotatable carrier plate 2 with an axis vertically arranged on the base 1, and a plurality of vertically arranged mixing drums uniformly distributed along the axis of the carrier plate 2 on the carrier plate 2 3. There is a stirring paddle 4 coaxially connected to the mixing drum 3 in the mixing drum 3; a planetary gear mechanism placed below the carrier plate 2 on the base 1 and coaxially arranged with the carrier plate 2, the planetary gear The ring gear 5 of the mechanism is rotationally connected with the base 1, the planetary gear 6 of the planetary gear mechanism is coaxially connected with the stirring paddle 4, and the sun gear 7 of the planetary gear mechanism is driven by a motor 8 and a reduction gear; the base 1 There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com