Microstructure keyway broach for surfaces of bionic dung beetle elytra, and preparation method thereof

A keyway broach and microstructure technology, which is applied to broaches, broaching machines, manufacturing tools, etc., can solve the problems that the bionic effect needs to be further developed, and the microstructure broaching performance cannot be brought into play, so as to improve the service life and protect the Tool, cutting load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below with reference to the accompanying drawings.

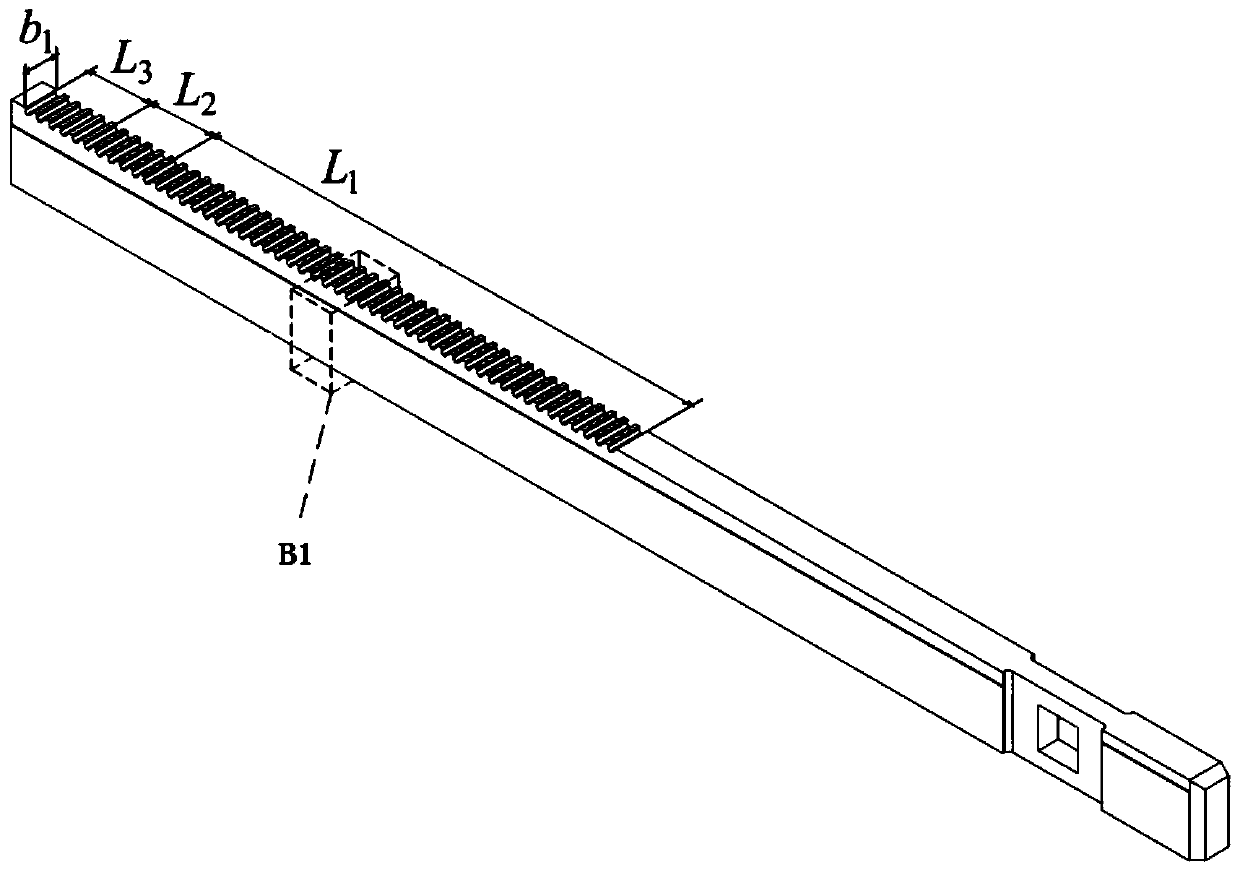

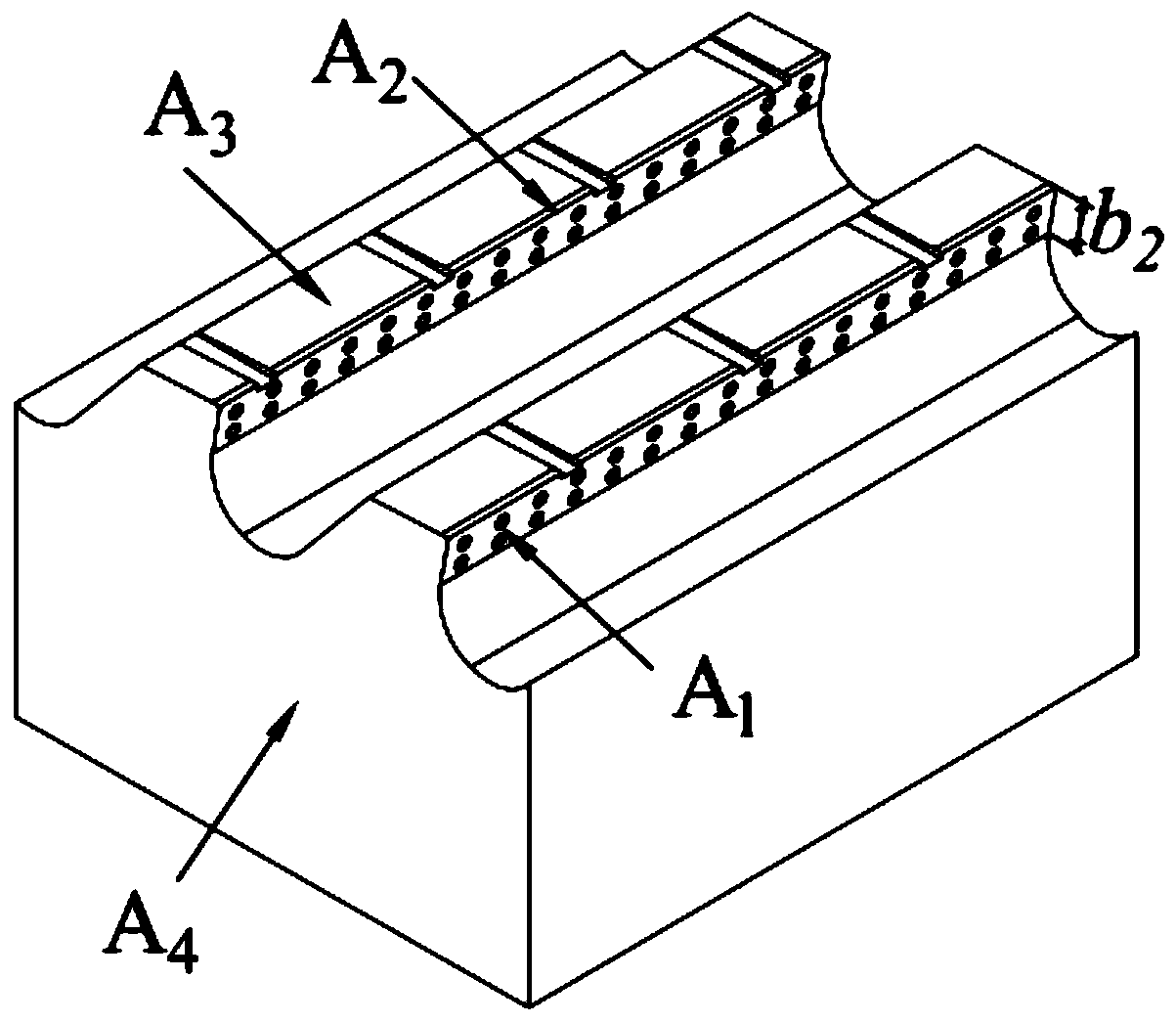

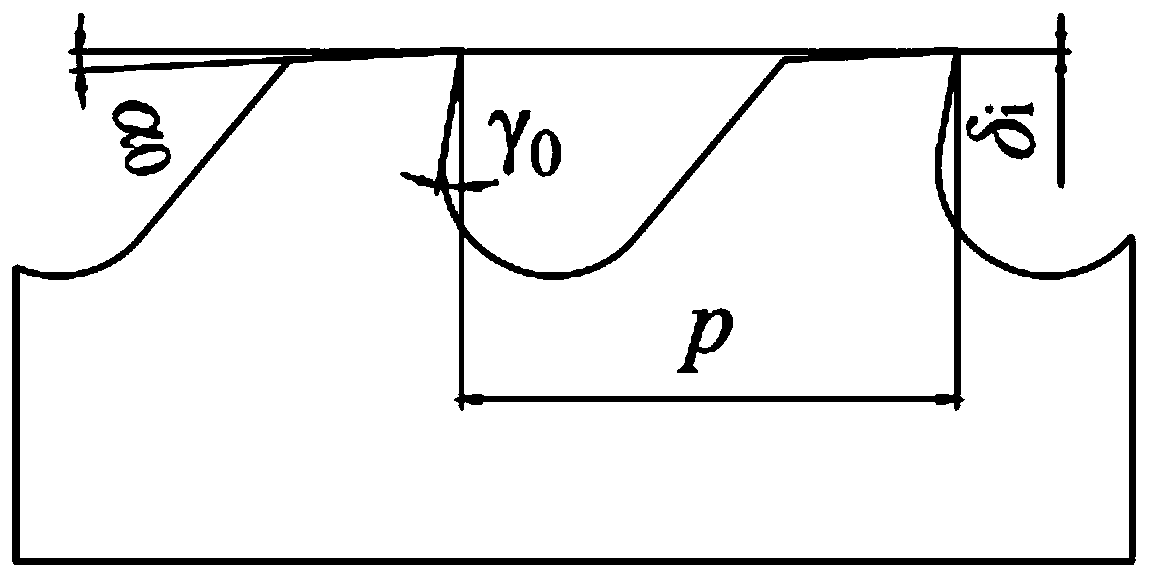

[0047] like Picture 1-1 , 1-2 As shown in and 1-3, the microstructure keyway broach imitating the surface of the dung beetle elytra of the present invention is made of high-speed steel (W6Mo5Cr4V2), and the specific dimensions of the broach are: the total length is 600mm, the tooth width is b 1 16mm, rake face width b 2 is 2mm, and the number of teeth is 50. Tooth Rake Angle¶ 0 is 12°, the rear angle α 0 is 6°, and the tooth pitch p is 6mm. The first 40 teeth are rough drawing area L 1 , its tooth lift δ i is 0.04mm, and the 41st to 45th teeth are semi-fine drawing area L 2 , its tooth lift δ i is 0.01mm, and the 46th to 50th teeth are the fine drawing area L 3 , its tooth lift δ i is 0mm. Teeth include rake face A 1 , Flank A 3 and blade A 2 , in the rough drawing area L 1 and semi-fine pull area L 2 Each tooth inside the rake face A 1 2 rows × 16 colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com