A process for purifying flue gas from spray granulation

A spray granulation and process technology, applied in the direction of gas treatment, dispersed particle separation, air quality improvement, etc., can solve the problems of a large amount of waste, complex process parameters, waste of resources, etc., to improve the adhesion effect, save the operation process, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A process for purifying flue gas from shotcrete granulation, comprising the steps of:

[0028] First, it is sprayed and washed through the spray washing tower, and the temperature is lowered to 35°C, and then it enters the reaction chamber equipped with microbial preparations for flue gas purification treatment. After the treatment is completed, it is discharged;

[0029] The microbial preparation is prepared according to the following process:

[0030] 1) Preparation of adsorption carrier: put the straw into the pulverizer, and pass through a 100-mesh sieve to obtain straw powder; , attapulgite and phosphoric acid solution were added to the reaction kettle according to the mass ratio of 5:10:1:12, stirred at 300rpm for 10min, and then entered into the drum granulator for granulation, the particle size was controlled to be 2mm, and then placed under the condition of 100°C , drying for 30min to obtain an adsorption carrier; the concentration of the phosphoric acid solut...

Embodiment 2

[0038] A process for purifying flue gas from shotcrete granulation, comprising the steps of:

[0039] First, spray and wash through the spray washing tower, lower the temperature to 33°C, and then enter the reaction chamber equipped with microbial preparations for flue gas purification treatment. After the treatment is completed, it is discharged;

[0040] The microbial preparation is prepared according to the following process:

[0041] 1) Preparation of adsorption carrier: put the straw into the pulverizer, and pass through a 100-mesh sieve to obtain straw powder; , attapulgite and phosphoric acid solution were added to the reaction kettle according to the mass ratio of 5:10:1:12, stirred at 300rpm for 10min, and then entered into the drum granulator for granulation, the particle size was controlled to be 2-3mm, and then placed at 100°C Under conditions, dry for 30 minutes to obtain an adsorption carrier; the concentration of the phosphoric acid solution is 0.1mol / L; the pa...

Embodiment 3

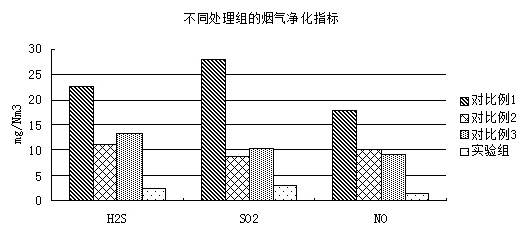

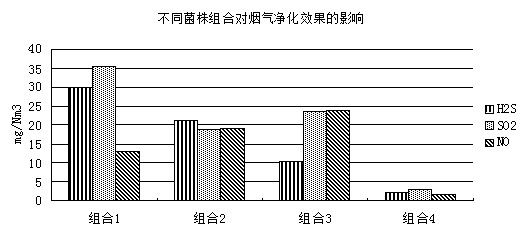

[0049] The spray granulation flue gas from the spray granulation workshop in Fufeng, Inner Mongolia was selected for treatment. The composition of the tail gas after spraying is as follows: H 2 S is 146.7mg / Nm 3 , SO 2 139.4mg / Nm 3 , NOx is 167.1mg / Nm 3 , the temperature is 33℃, and the space velocity is 5000h -1 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com