Method for boiler flue gas multi-stage heat exchange white smoke removal

A technology for boiler flue gas and flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as flue gas tailing, achieve the effect of eliminating flue gas tailing and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

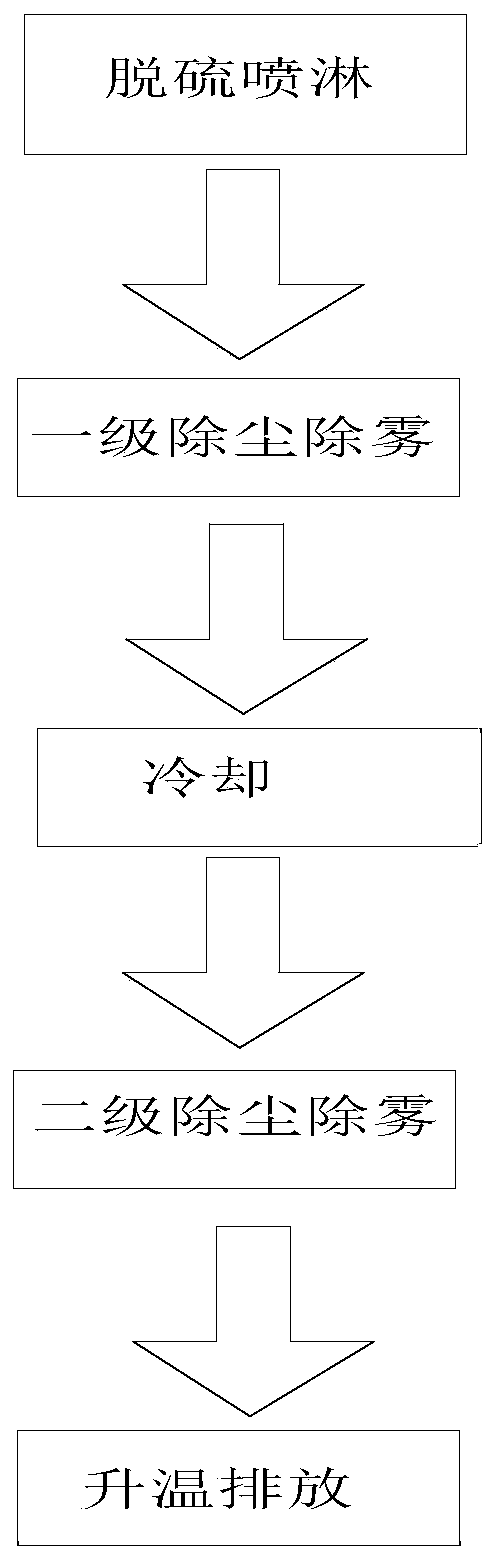

[0053] Such as figure 1 As shown, a method for multi-stage heat exchange dewhitening of boiler flue gas comprises the following steps:

[0054] S1: Desulfurization spraying, the boiler flue gas enters the desulfurization tower for desulfurization by spraying, the flue gas enters from the lower part of the desulfurization spraying area and contacts the desulfurization spraying liquid countercurrently, after passing through the desulfurization spraying area, it is saturated or nearly saturated by water vapor, and the flue gas After desulfurization and spraying, the temperature drops to 55-70°C; S2: first-stage dust and fog removal, the flue gas after S1 desulfurization continues to flow to the upper part of the desulfurization tower at a flow rate of 5m / s-10m / s, and enters the first-stage swirl plate Dust and mist eliminator, under the guidance of the swirl plate, the flue gas rotates at a high speed in the swirl plate dust and mist eliminator to remove water mist and fine dust ...

Embodiment 2

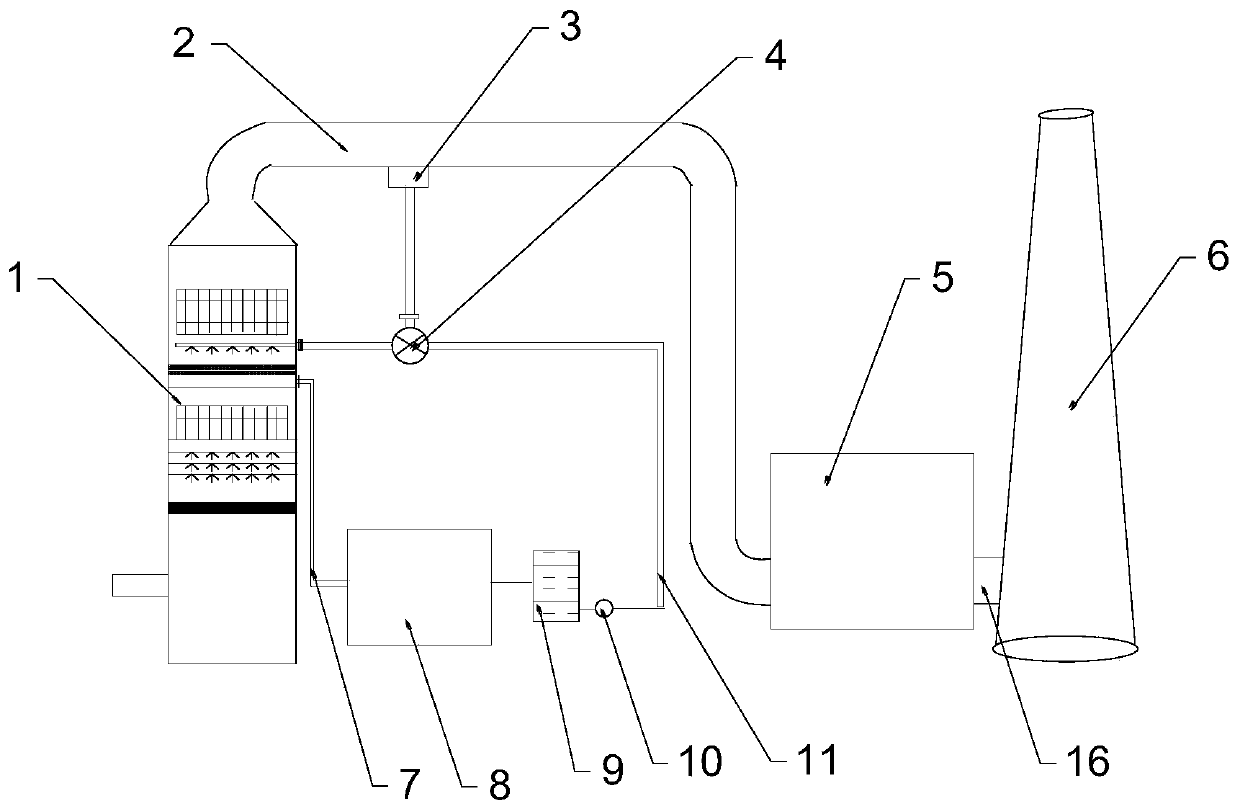

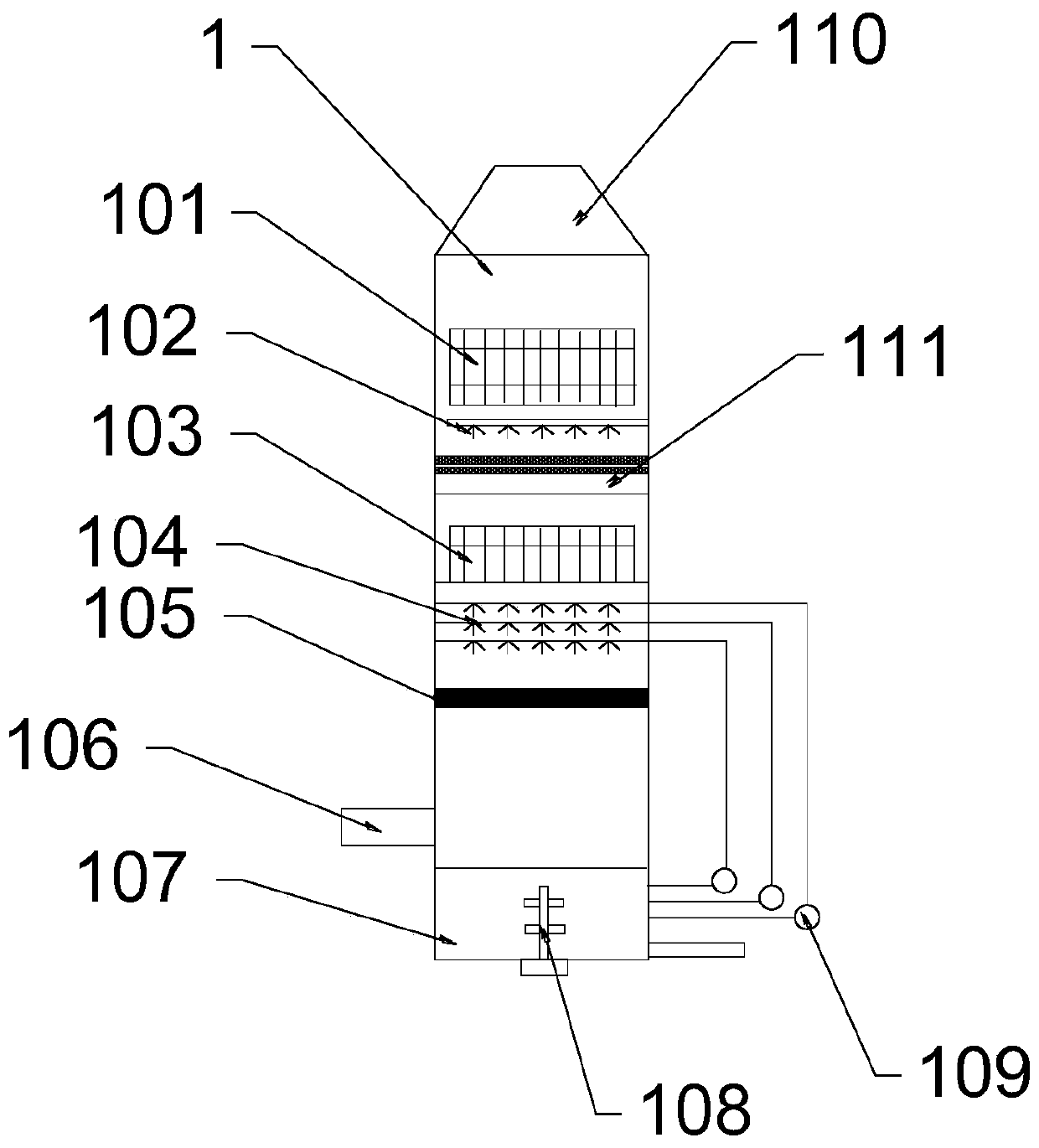

[0059] Such as figure 2 As shown, the first spray pipe 104 is connected to the slurry tank 107 through a circulation pump 109, the slurry tank 107 is provided with an agitator 108, and the first spray pipe 104 is provided with at least two layers. Further, the The flue gas inlet of the desulfurization tower is connected to the boiler through a dust collector and an induced draft fan in sequence, and the end of the slurry tank far away from the air inlet is provided with a liquid discharge port, and the liquid discharge port is connected to a cyclone, and the liquid collection tank is drained by a circulating pump 109. The desulfurization liquid in 107 is sprayed into the desulfurization tower 1 through the first spray pipe 104, sprayed to the reaction area after being atomized by the nozzle, and the contact area between the slurry and the flue gas is increased to realize the desulfurization of the flue gas. There are conventional agitators with technology, the agitator 108 st...

Embodiment 3

[0061] Described heat exchanger 105 adopts any one of glass plate, silicon carbide ceramic tube, fluoroplastic heat exchanger, preferred heat exchanger 105 adopts fluoroplastic heat exchanger, and the pipe diameter of described fluoroplastic heat exchanger is 10 ~50mm, wall thickness 1~1.5mm, the fluoroplastic heat exchanger adopts modular design, the tube bundle includes 600~5000 tubes, the tubes are separated and fixed by fluoroplastic coils, fluoroplastic Strong corrosion resistance, stable chemical properties, can be used normally in the range of -190 ° C ~ 220 ° C, smooth surface and moderate flexibility, not easy to scale, low smoke resistance, aging resistance, long service life and self-cleaning Function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com