Positive electrode material, preparation method thereof, battery positive electrode, and lithium ion battery

A positive electrode material, battery positive electrode technology, applied in the field of materials, can solve the problems of reducing electronic products, existing safety hazards, automatic shutdown, etc., to achieve the effects of large capacity, simple and convenient operation, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

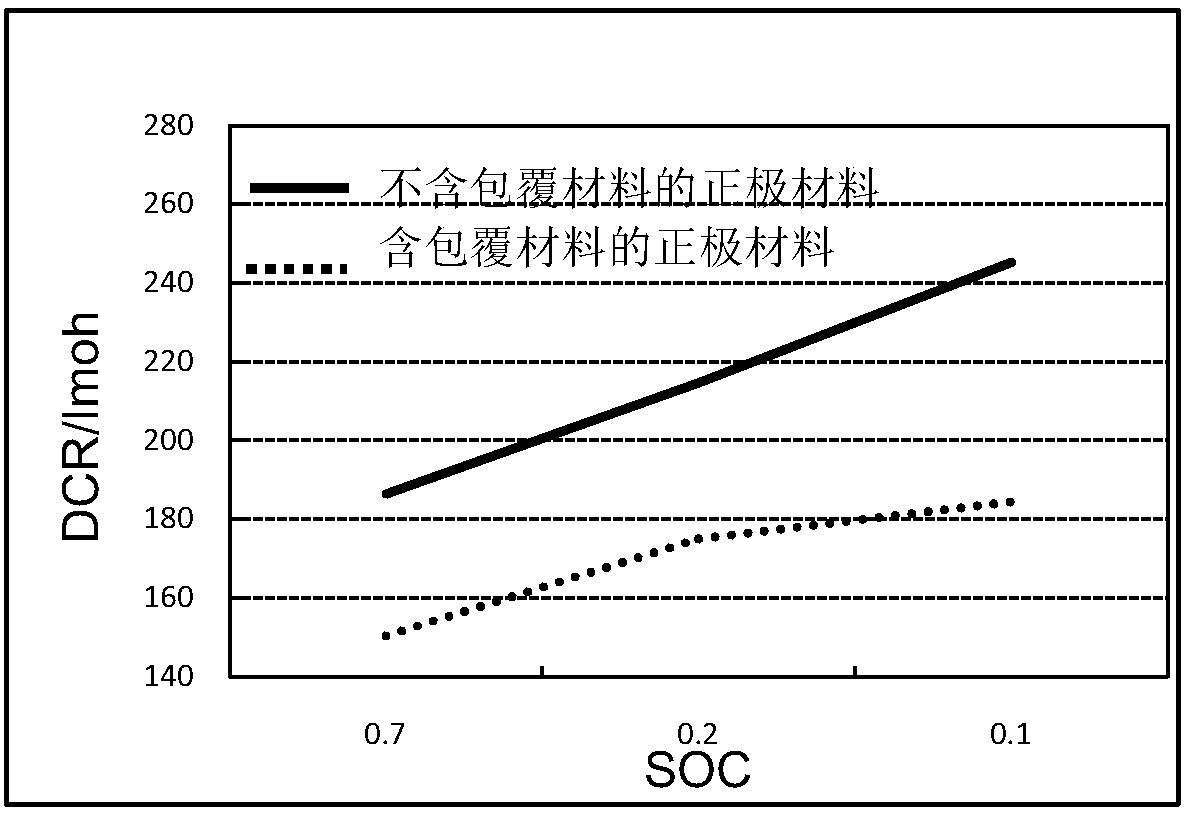

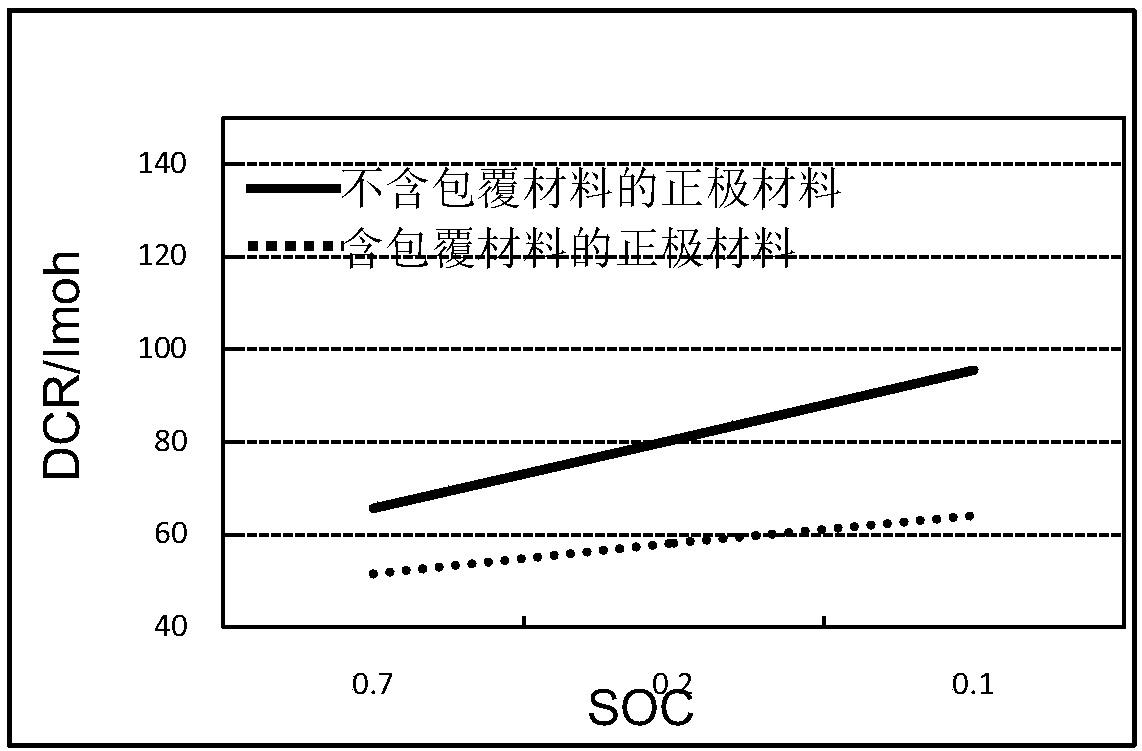

[0093] 0.62g LiOH·H 2 O, 6.67g Gd(NO 3 ) 3 ·6H 2 O and 3.9g (NH 4 ) 2 HPO 4 Dissolve in water, stir to mix, and react to form a white precipitate. After filtering out the precipitated substance, dry it, grind it, sieve it, add 5000g LiCoO 2 , after ball milling in a high-energy ball mill for 24 hours, calcined at 650°C for 3 hours in an air atmosphere; the sintered samples were crushed and sieved to obtain LiGdP with an average particle size of about 4 μm 2 o 7 coated cathode material. For the obtained LiGdP 2 o 7 The coated cathode material was prepared as a full cell and tested for DCR.

Embodiment 2

[0095] The preparation method is consistent with that of Example 1, except that what is obtained in Example 2 is LiGdP with an average particle size of about 10 μm 2 o 7 coated cathode material.

Embodiment 3

[0097] The preparation method is the same as in Example 1, except that what is obtained in Example 3 is LiGdP with an average particle size of about 15 μm 2 o 7 coated cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com